New energy automobile steering controller cover and cable assembly table

A technology for steering controllers and new energy vehicles, applied in electric vehicles, vehicle parts, vehicle energy storage, etc., can solve the problems of different colloid extrusion, uneven colloid smearing, inconvenient use, etc., and achieve the effect of convenient reuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

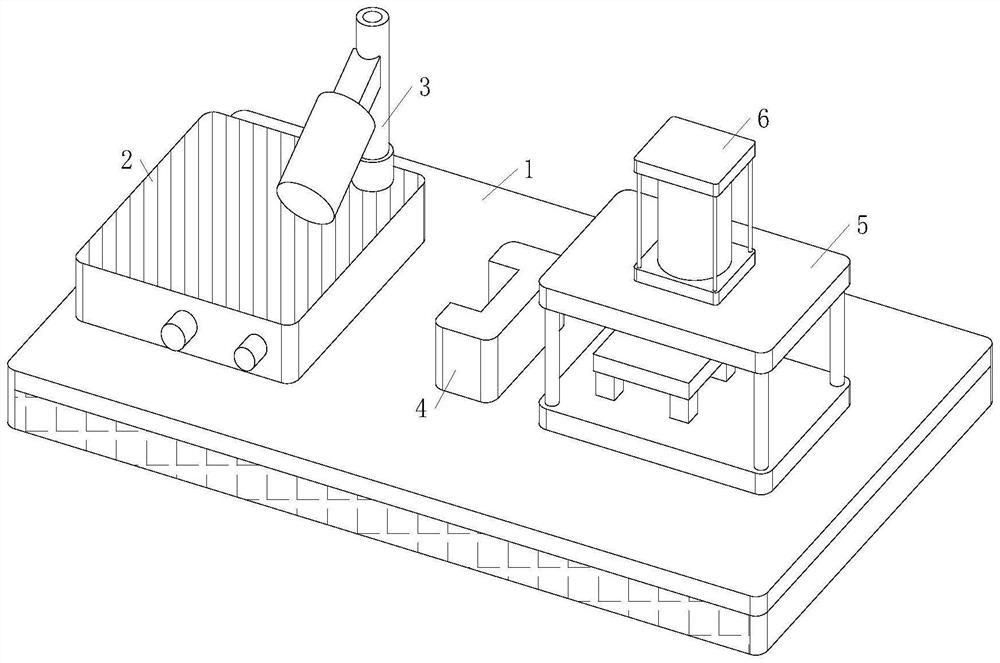

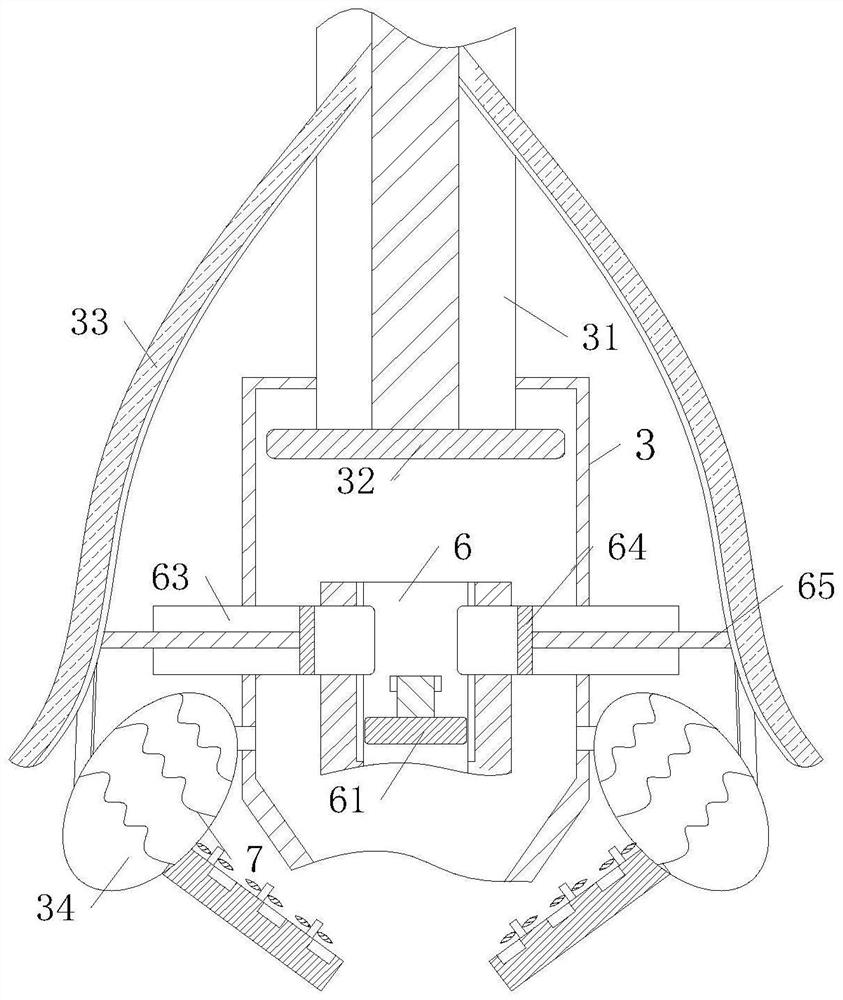

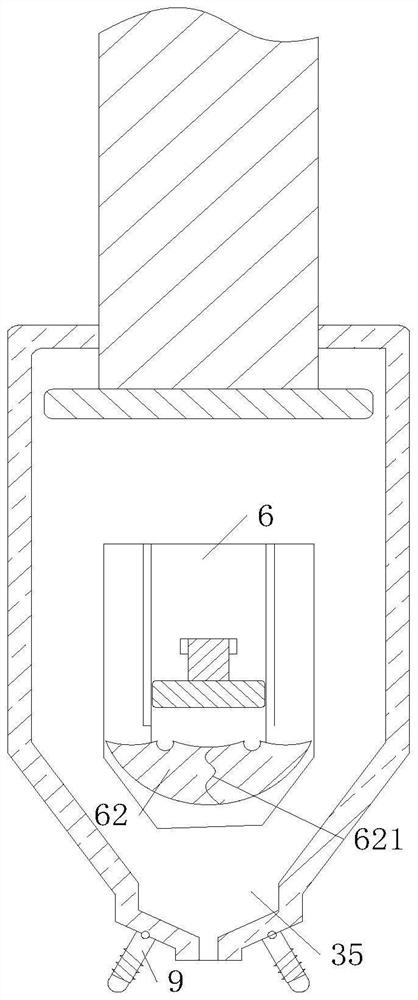

[0031] like Figure 1 to Figure 5 As shown, a new energy vehicle steering controller cover and cable assembly platform according to the embodiment of the present invention includes a workbench 1, and a placement plate 2 is fixedly connected to the left side of the upper surface of the workbench 1. The upper surface of the board 2 is fixedly connected with a gluing cylinder 3, the middle part of the upper surface of the workbench 1 is fixedly connected with an assembly seat 4, and the right side of the upper surface of the workbench 1 is fixedly connected with a test seat 5, and the test seat The upper surface of 5 is fixedly connected with a lower press 8. In this embodiment, a plurality of code scanning seats are arranged on the upper surface of the worktable 1, and a loading cavity 31 is fixedly connected to the upper side of the gluing cylinder 3, so The inside of the loading chamber 31 is slidably connected with a piston rod 32 , and the left and right sides of the piston ...

Embodiment 2

[0040] like Image 6 As shown, comparative example one, wherein another embodiment of the present invention is:

[0041] The inside of the assembly seat 4 is provided with a through groove, the inside of the assembly seat 4 is slidably connected with a push column 41 , the push column 41 is slidably connected to the inside of the through groove, and the push column 41 is close to the inner wall of the assembly seat 4 . A compression spring 42 is fixedly connected to one side, a first convex seat 43 is fixedly connected to the surface of the push column 41 , a slot is formed on the surface of the assembly seat 4 , and the surface of the assembly seat 4 is slidably connected in the slot. There is a clamping rod 44, and the side of the clamping rod 44 close to the first convex seat 43 is fixedly connected with a second convex seat 45; when the glue is applied, the cable and the controller cover are screwed together, and the controller cover is screwed. Place it on one side of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com