Direct current screen capable of rapidly extinguishing fire

A DC screen and fast technology, applied in the field of DC screen, can solve problems such as damage to electrical components and inability to carry out self-extinguishing fire-fighting treatment, and achieve the effect of reducing fire and facilitating use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

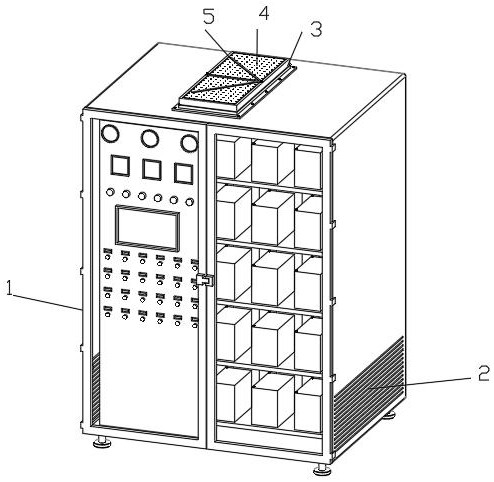

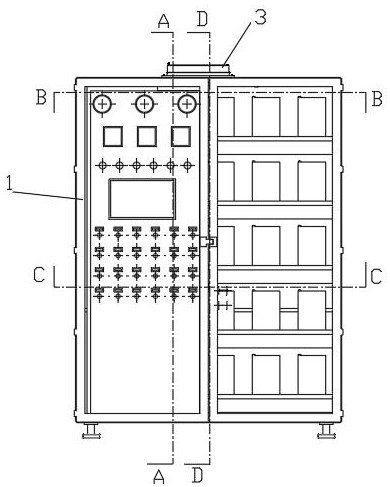

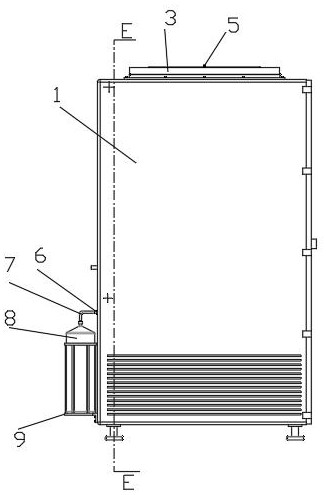

[0043] like Figure 1-13The DC screen that can quickly extinguish the fire includes the DC screen body 1, the air outlet 2 and the leakage protector 25. The electric control input end and the electronic control output end of the DC screen body 1 are connected with a leakage protector 25, and the top of the DC screen body 1 is connected There is an air intake structure, the top of the air intake structure is provided with a filter screen 4, the top of the air intake structure is provided with a pressing structure for pressing the filter screen 4, the bottom of the air intake structure is connected with an air intake blocking structure, and the DC screen body is on one side. The lower end of the wall is evenly provided with air outlet holes 2, and the DC screen body 1 is connected with an air outlet blocking structure for blocking the air outlet holes 2 at the inner side of the air outlet hole 2. Connected with rapid fire extinguishing structure.

[0044] It can carry out self-...

Embodiment 2

[0046] On the basis of Example 1, see figure 1 , 2 , 3 and 5, the air intake structure includes an air intake hood 3 and a fan 18. The air intake hood 3 is fixed with a fan 18 at equal intervals through the mounting frame. 4 is installed on the inner top of the air intake hood 3 .

[0047] The fan 18 of the air intake structure drives the air flow, and the air flows into the DC screen body 1, and drives a large amount of heat generated in the DC screen body 1 away for rapid cooling, which is beneficial to the use of electrical components and reduces the possibility of fire.

Embodiment 3

[0049] On the basis of Example 2, see figure 1 , 2 , 3, 4 and 10, the pressing structure includes a baffle 5, a connecting shaft 10, a locking rod 31 and a first spring 32. A connecting shaft 10 is fixed at one end of the top of the air inlet cover 3, and the connecting shaft 10 is connected to one end of the baffle 5. Rotationally connected, the top of the other end of the baffle 5 is connected with a first spring 32, the top of the first spring 32 is fixed with a lock rod 31, and the other end of the top of the air inlet cover 3 is inserted into the bottom of the lock rod 31 through the opening hole.

[0050] Pull the locking rod 31 of the pressing structure upward to move, then rotate the baffle 5, take out the filter screen 4 and place the new filter screen 4 in the air intake hood 3, rotate the baffle 5 along the connecting shaft 10, the baffle 5 After the rotation, the first spring 32 drives the lock rod 31 to move, and the lock rod 31 is inserted into the hole opened a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com