Detection tool and method for detecting square groove of fifth balance block of crankshaft

A technology of balance weights and crankshafts, which is applied in the field of auto parts manufacturing, can solve the problems of not being suitable for mass production product testing, being unable to perform testing, and slow testing beats, etc., to achieve stable and reliable testing, good consistency, and low production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

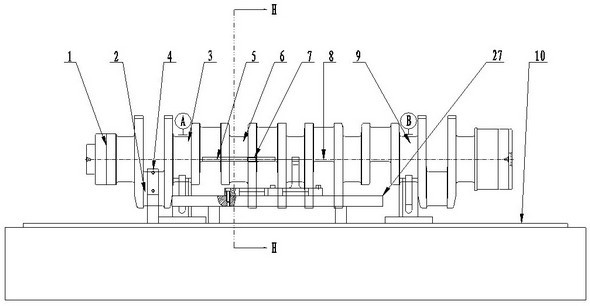

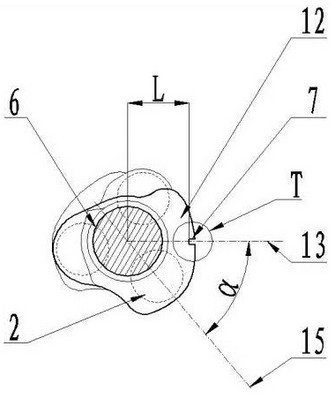

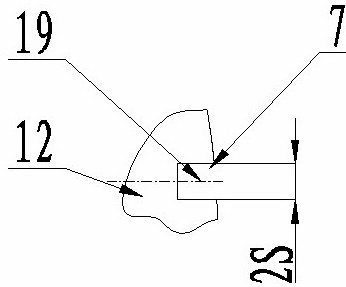

[0030] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 As shown, the inspection tool of the present invention mainly includes a square groove depth inspection tool for detecting the square groove of the fifth balance block 12, a square groove position degree inspection tool and a standard part 37, a measuring key 5, a small platform 27, and two sets of roller supports. seat 26, angular positioning seat 21, etc.

[0031]The small platform 27 is connected to the operation side of the large platform 10 by bolts 5 40 and 641. After the small platform 27 is installed, it does not interfere with the crankshaft 1 and the roller support seat 26; the upper surface of the small platform 27 is parallel to the upper surface of the large platform 10. The distance between the upper surface of the small platform 27 and the crankshaft center line 8 is H; the roller suppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com