Forging device for special material forge piece of maritime work equipment and forging method of forging device

A technology of special materials and equipment, applied in the field of forging, can solve the problems of difficulty in controlling the rotation of the ring billet, reducing forging efficiency, and difficult operation, so as to achieve the effect of improving forging effect, improving forging efficiency, and low operation degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

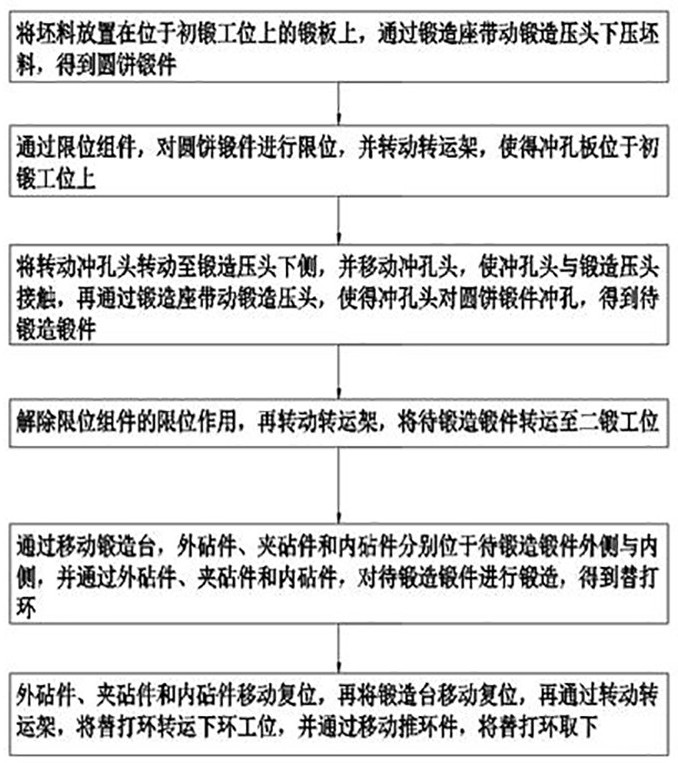

Method used

Image

Examples

Embodiment

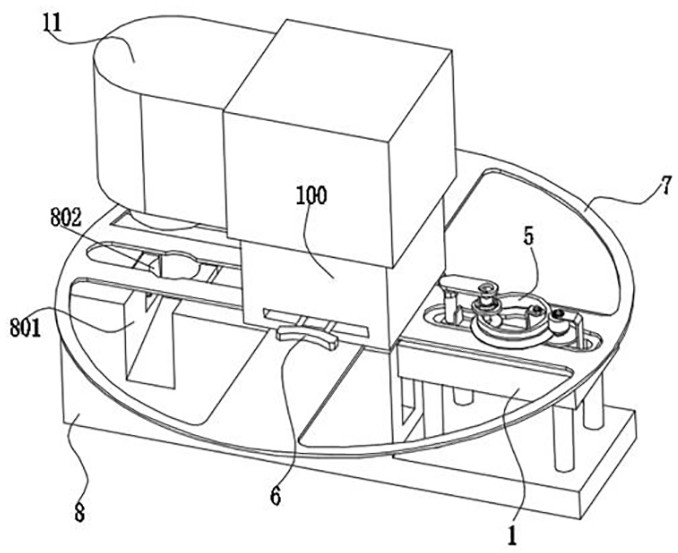

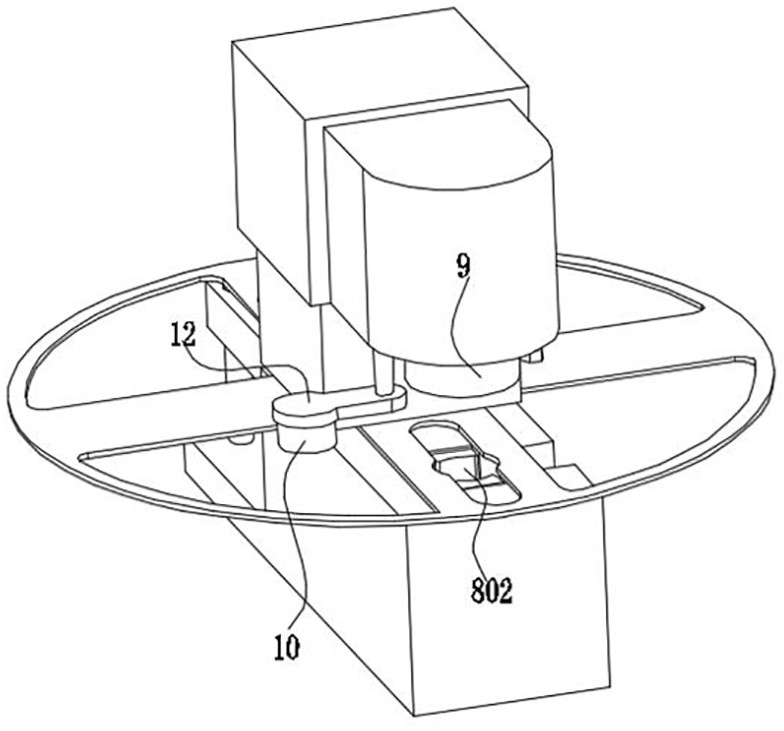

[0046] For a forging device of a special material forging of marine equipment in this embodiment, refer to Figure 2-12 : Including a replacement ring mechanism, the replacement ring mechanism includes a forging table 1, an outer anvil piece 2, an anvil clamping piece 3 and an inner anvil piece 4, wherein the forging table 1 is set horizontally, and the upper side of the forging table 1 (with figure 2 For the reference direction, the same below) is provided with a groove 101, and the outer anvil 2, the clamping anvil 3 and the inner anvil 4 slide in sequence from right to left on the forging table 1, and the three are on the same straight line.

[0047] The outer anvil 2 includes an outer anvil frame 202 and an outer anvil wheel 201 that rotates in the outer anvil frame 202; wherein, the outer anvil frame 202 slides in the groove 101, and the outer anvil wheel 201 includes a special shape for extruding the outside of the forging to be forged. Wheel 2011, the side of the cross...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com