Enterprise green production management and control method and system based on big data

A green production and big data technology, applied in the field of data processing, can solve the problems of low pollution control quality and inability to accurately analyze the production process of enterprises.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

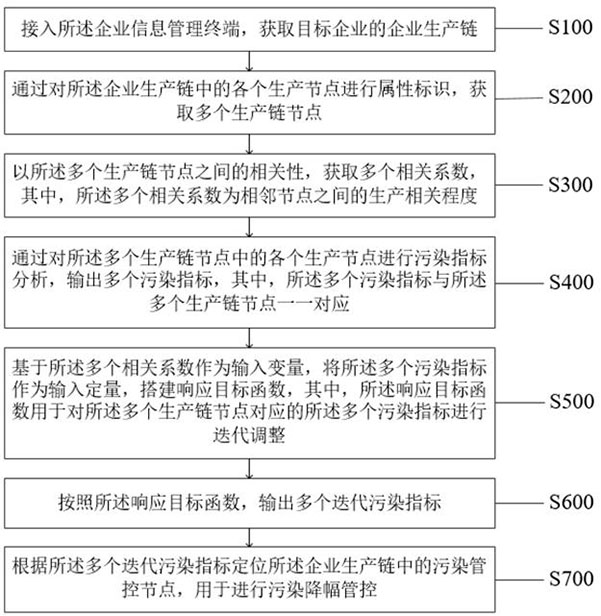

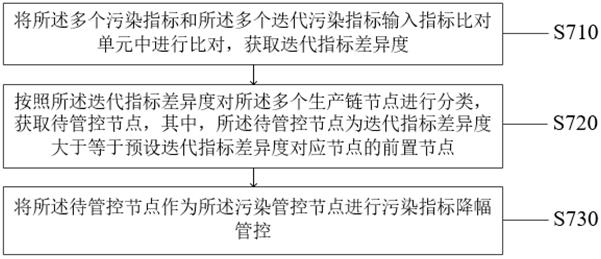

[0021] like figure 1 As shown, the present application provides a big data-based enterprise green production management and control method, wherein the method is applied to an enterprise green production management and control system, and the system is communicatively connected to an enterprise information management terminal, and the method includes:

[0022] Step S100: accessing the enterprise information management terminal to obtain the enterprise production chain of the target enterprise;

[0023] Specifically, the enterprise information management terminal is a terminal that manages information in the entire production cycle of the enterprise, and can store, call, and process enterprise information. The target enterprise refers to any enterprise that needs to conduct green production management and control. The enterprise production chain refers to the process and the main body involved in the process of a certain product in the enterprise from project initiation to pro...

Embodiment 2

[0073] Based on the same inventive concept as the big data-based enterprise green production management and control method in the foregoing embodiment, such as Figure 4 As shown, the present application also provides an enterprise green production management and control system based on big data, wherein the system includes:

[0074] A production chain acquisition module 11, the production chain acquisition module 11 is used to access the enterprise information management terminal to acquire the enterprise production chain of the target enterprise;

[0075] Node acquisition module 12, the node acquisition module 12 is configured to acquire a plurality of production chain nodes by performing attribute identification on each production node in the production chain of the enterprise;

[0076] Correlation coefficient acquisition module 13, the correlation coefficient acquisition module 13 is used to obtain a plurality of correlation coefficients based on the correlation between th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com