Servo mechanism with guide rail matched with ball screw pair and transmission method of servo mechanism

A technology of ball screw pair and servo mechanism, which is applied in the field of servo transmission system, can solve the problems of material wear, system jitter, small signal tracking ability affecting the deflection accuracy of the servo system, etc., to eliminate fit clearance, reduce friction, and avoid output accuracy low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

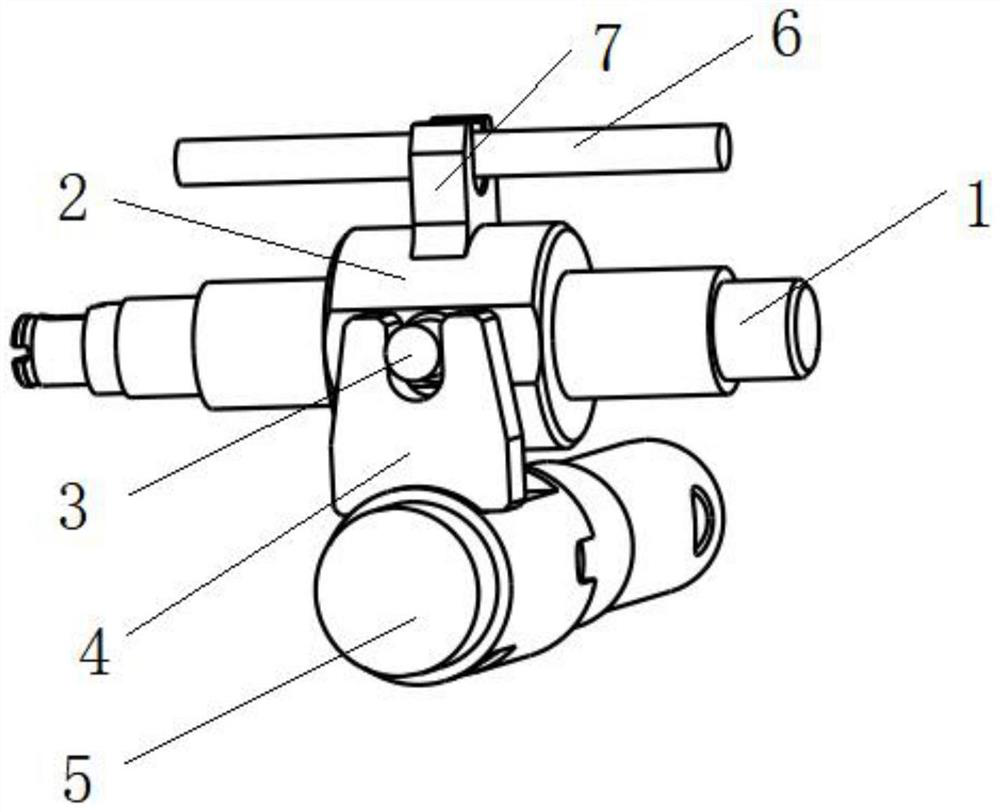

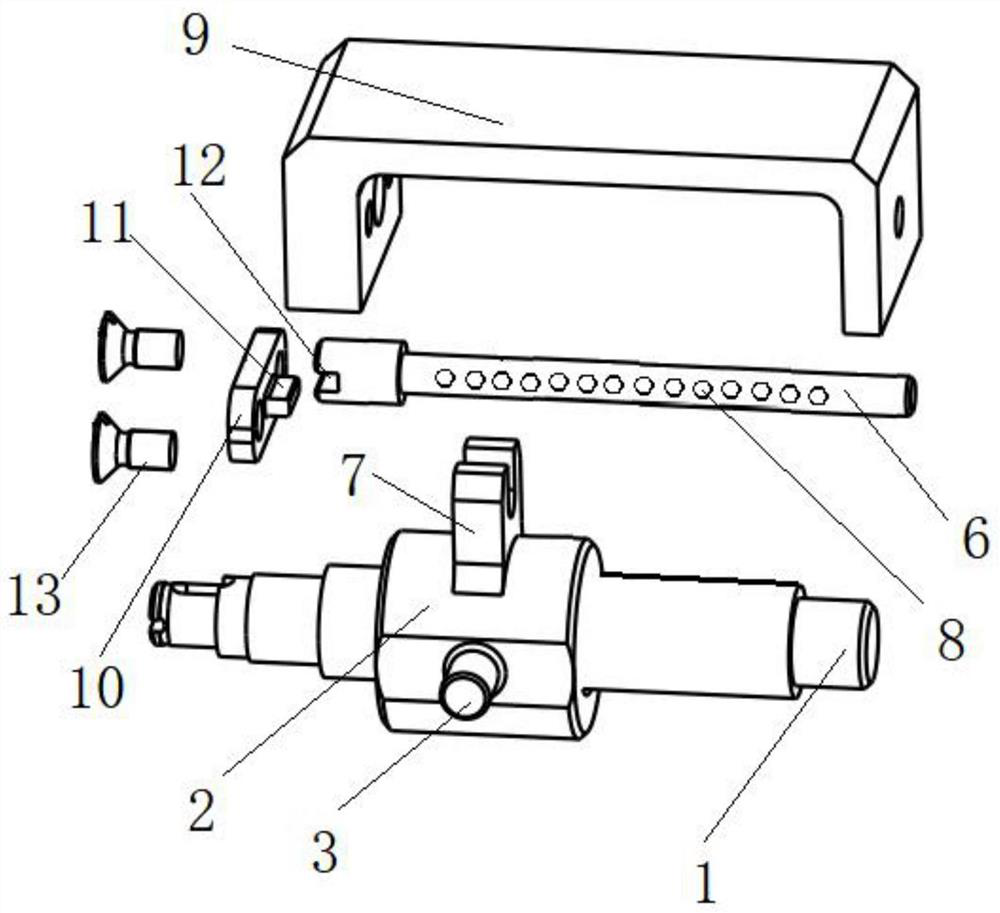

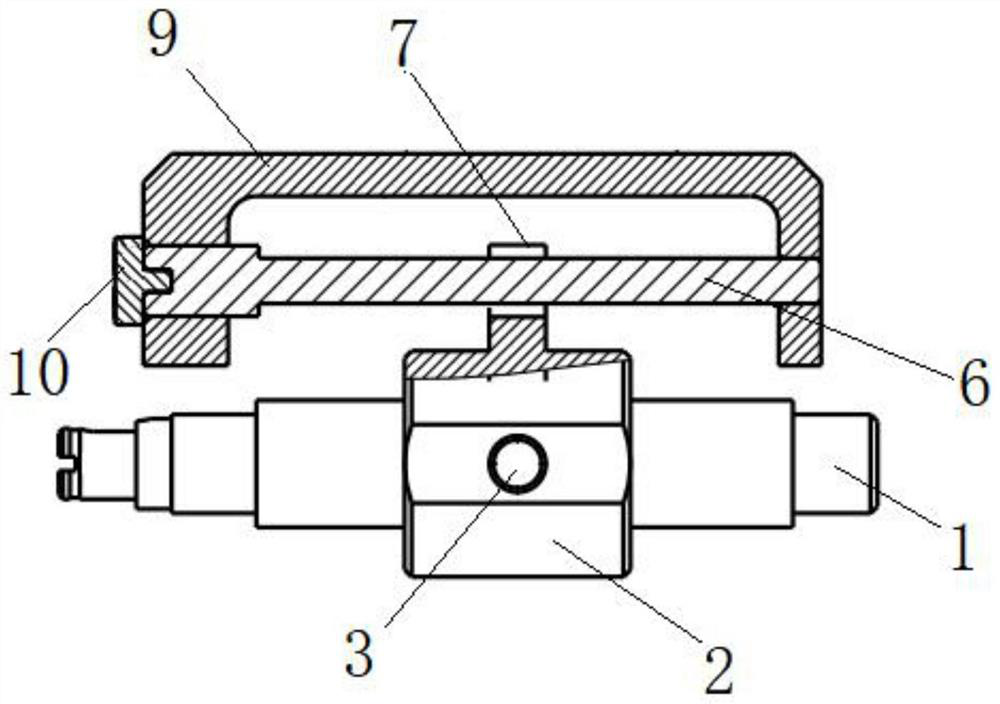

[0042] A specific embodiment of the present invention, such as Figure 1-9 As shown, a servo mechanism with a guide rail and a ball screw pair is disclosed, including: a lead screw 1, a ball nut 2, a guide rail 6, a shift fork 4 and an output shaft 5, wherein the lead screw 1 and the ball nut 2 form a screw Lever nut pair.

[0043] Further, as figure 1 As shown, the ball nut 2 is provided with a lug 7 and a trunnion 3, the lug 7 is provided with a U-shaped groove, and the lug 7 is matched with the guide rail 6 through the U-shaped groove and can slide relatively; when the lead screw 1 rotates, The ball nut 2 slides along the guide rail 6, and the shift fork 4 is undulated by the trunnion 3, and the output shaft 5 is driven by the shift fork 4 to rotate through a certain angle.

[0044] Further, as Figure 4 As shown, the lug 7 and the trunnion 3 are both integrally formed with the ball nut 2, and the lug 7 and the trunnion 3 are perpendicular to each other.

[0045] Furthe...

Embodiment 2

[0078] A specific embodiment of the present invention provides a transmission method of the servo mechanism in which the guide rail and the ball screw pair cooperate with the guide rail in the first embodiment, including the following steps:

[0079] Step S1: the motor drives the lead screw 1 to rotate;

[0080] Step S2: the lead screw 1 and the ball nut 2 form a lead screw nut pair, and the lead screw 1 drives the ball nut 2 to slide along the guide rail 6;

[0081] Step S3: The trunnion 3 slides the ball nut 2 synchronously, and drives the output shaft 5 to deflect.

[0082] In the step S2, the ball nut 2 is matched with the guide rail 6 through the support lug 7; Side contact; when the ball nut 2 slides relative to the guide rail 6, the ball 8 rolls relative to the lug 7.

[0083] Through the contact between the balls 8 and the lugs 7, the sliding friction is replaced by rolling friction, and the line contact is replaced by point contact. In the process of sliding the bal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com