Mounting and fixing method of electric hanging basket suspension mechanism

A technology of suspension mechanism and fixing method, which is applied in the direction of scaffolding supported by house structure, building structure, scaffolding accessories, etc. It can solve the problems that the top floor cannot meet the conventional counterweight, installation is inconvenient, installation and fixing, etc., so as to save equipment rental Cost, practicality, and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

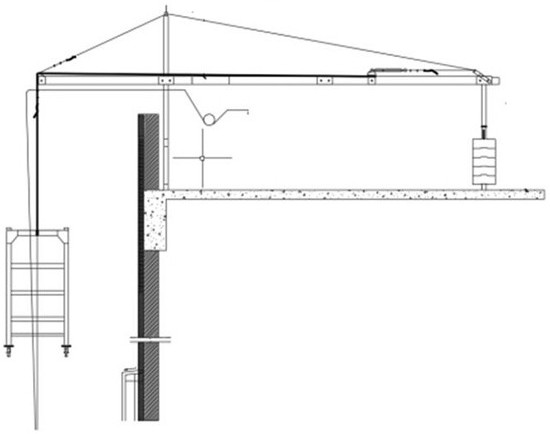

[0023] see now figure 1 , figure 1 Schematic diagram of the installation and fixing structure for the hanging basket of the traditional suspension mechanism. As shown in the figure, in the conventional suspension mechanism, the front bracket is fixed on the floor, and the rear bracket is fixed on the floor with a standard counterweight placed thereon. However, the top structure of the construction site is a flower trellis beam, and the rear beam of the roof hanging basket suspension structure cannot be installed and fixed on the roof plane with traditional counterweights.

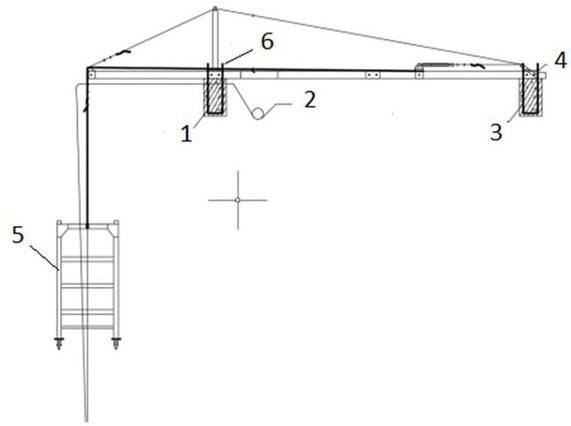

[0024] The installation and fixing method of the electric hanging basket suspension mechanism of the present invention, figure 2 It is a schematic diagram of the hanging basket installation and fixing structure of the embodiment of the present invention. The front bracket and the rear bracket in the conventional setting are cancelled, and the installation method of tying the flower frame beam is to fix t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com