Assembled resin module wall structure

A wall structure and assembly technology, applied in the direction of walls, building components, building structures, etc., can solve problems such as limiting the demand and application of resin modules combined walls, poor overall stability of resin walls, and inability to guarantee overall stability. , to achieve the effect of improving construction efficiency and construction quality, reliable assembly, and convenient plugging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below with reference to the accompanying drawings and specific embodiments.

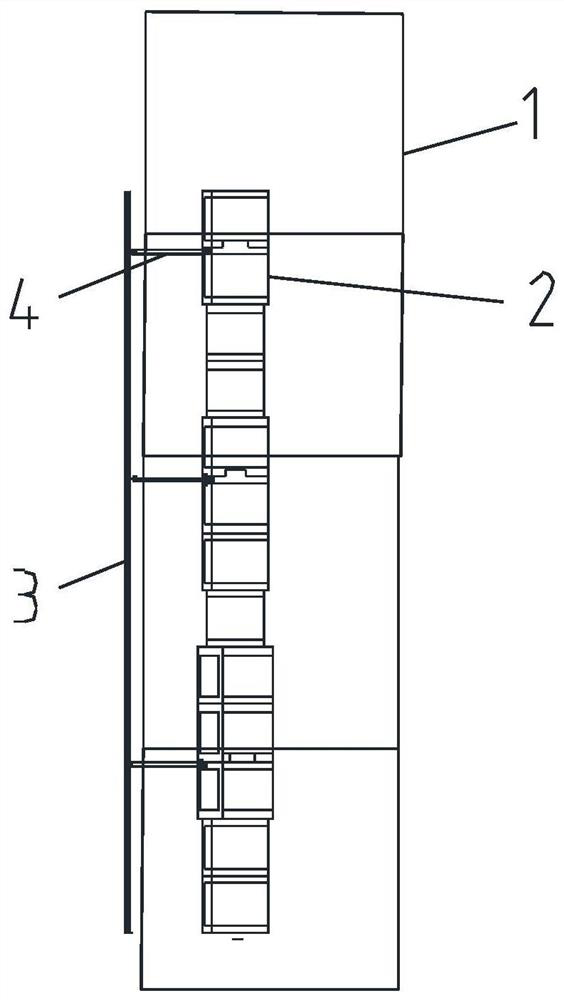

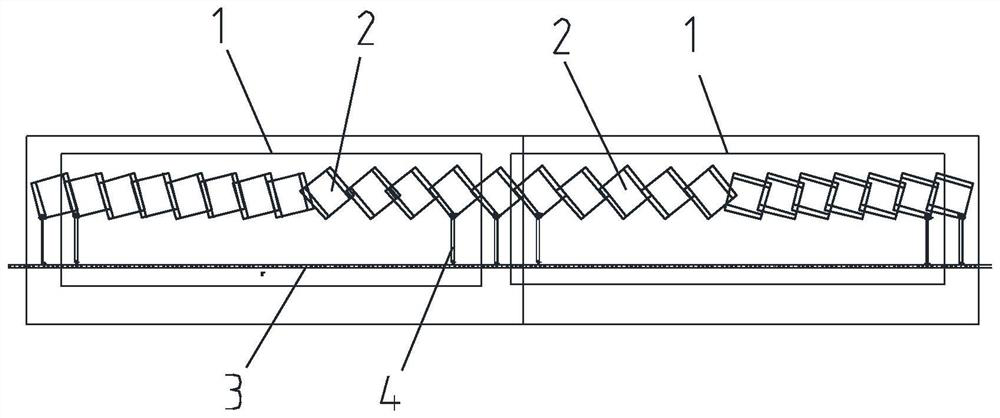

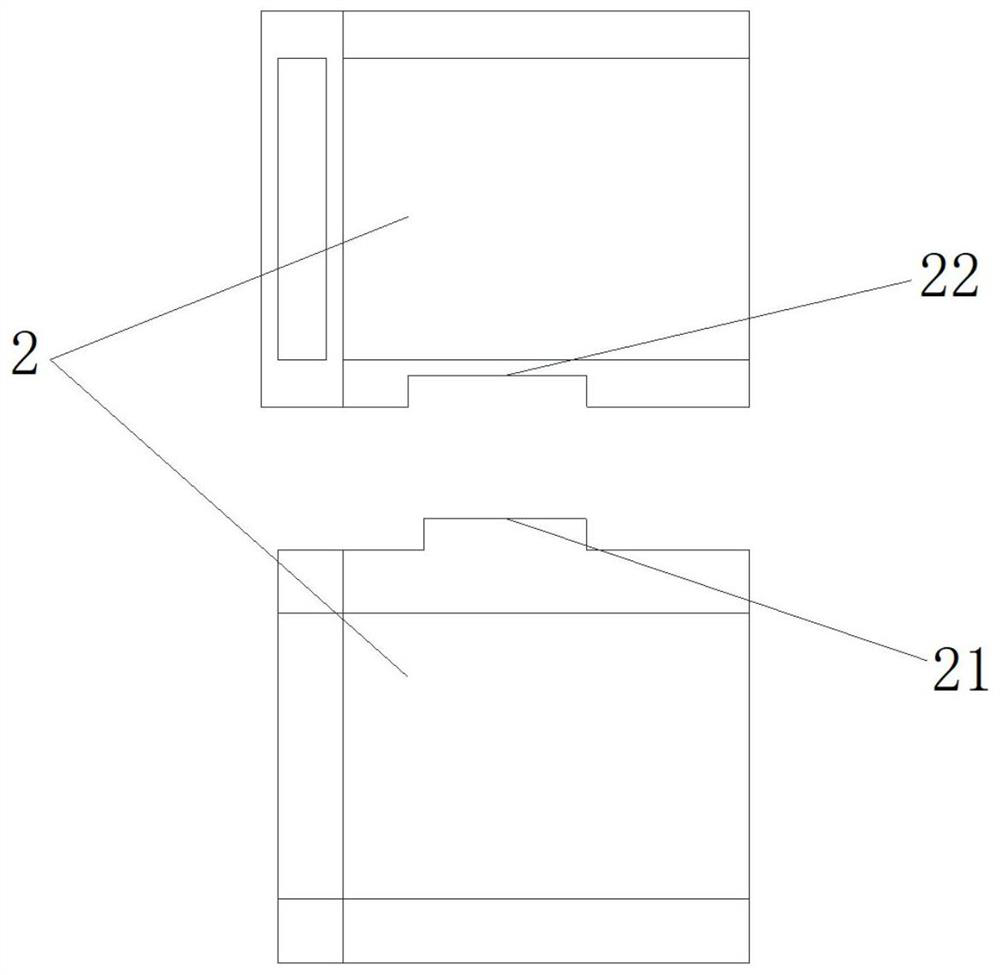

[0024] Please see attached figure 1 to the attached Figure 4 , an assembled resin module wall structure, including a module wall unit 1, several modular wall units 1 can be spliced horizontally, vertically and obliquely to form a resin module wall, and each module wall unit 1 passes through Several groups of tie rod assemblies 4 are fixedly installed on the building components 3; each modular wall unit 1 is formed by splicing several resin modules 2 horizontally and vertically in turn, and is located in the multiple resin modules 2 on the top of the modular wall unit 1. A connection bump 21 is formed on the top of the block resin module 2, which is located in the plurality of resin modules 2 at the bottom of the modular wall unit 1, and a connection groove 22 is formed at the bottom of each resin module 2, and the connection bump 21 is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com