Hybrid power system

A hybrid power system and meshing technology, which is applied in the field of automobile hybrid power transmission system, can solve the problems of difficult shifting, large speed ratio difference, and large fluctuation range of engine speed ratio, etc., and achieve high-efficiency parking power generation function and small speed ratio difference Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

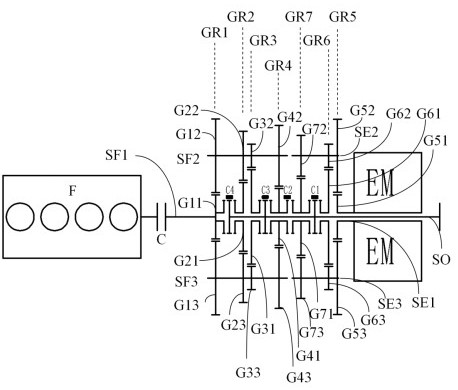

[0135] The present invention provides a hybrid power system, such as figure 1 Shown is the first embodiment of the present invention, in this embodiment, the hybrid power system includes an engine F, the output shaft of which is connected to the engine input shaft SF1 via a total clutch C; the engine input shaft SF1 passes through the first The gear set GR1 connects the engine first intermediate shaft SF2 and the engine second intermediate shaft SF3; the engine first intermediate shaft SF2 and the engine second intermediate shaft SF3 can selectively pass through the second, third and fourth gear sets GR2, respectively, GR3, GR4 are connected with the system output shaft SO; the output power of the engine is transmitted to the first intermediate shaft SF2 of the engine and the second intermediate shaft SF3 of the engine through the first gear set GR1, and then selectively through the second, third, or first intermediate shaft. The four gear sets GR2, GR3, GR4 are transmitted to...

no. 2 example

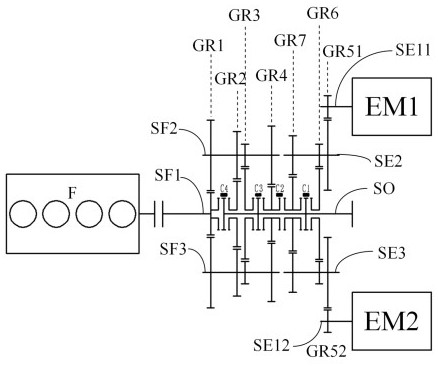

[0165] like figure 2 Shown is a hybrid power system provided by the second embodiment of the present invention, and the hybrid power system includes:

[0166] Engine F, the output shaft of which is connected to the engine input shaft SF1 via the total clutch C; the engine input shaft SF1 is connected to the engine first intermediate shaft SF2 and the engine second intermediate shaft SF3 through the first gear set GR1; An intermediate shaft SF2 and a second intermediate shaft SF3 of the engine are selectively connected to the system output shaft SO through the second, third and fourth gear sets GR2, GR3 and GR4, respectively.

[0167] The first motor EM1, the first motor output shaft SE11 is connected to the motor first intermediate shaft SE2 through the fifth and first gear set GR51, and the motor first intermediate shaft SE2 can selectively pass through the sixth and seventh gear sets GR6, respectively, GR7 is connected to the system output shaft SO.

[0168] For the secon...

no. 3 example

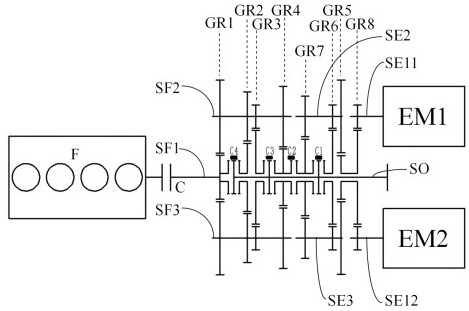

[0176] like image 3 Shown is a hybrid power system provided by a third embodiment of the present invention, and the hybrid power system includes:

[0177] Engine F, the output shaft of which is connected to the engine input shaft SF1 via the total clutch C; the engine input shaft SF1 is connected to the engine first intermediate shaft SF2 and the engine second intermediate shaft SF3 through the first gear set GR1; An intermediate shaft SF2 and a second intermediate shaft SF3 of the engine are selectively connected to the system output shaft SO through the second, third and fourth gear sets GR2, GR3 and GR4, respectively.

[0178]The first motor EM1, the first motor output shaft SE11 is connected to the fifth gear set GR5 through the eighth gear set GR8, and the fifth gear set GR5 is respectively connected to the motor first intermediate shaft SE2 and the motor second intermediate shaft SE3, so The first intermediate shaft SE2 of the motor and the second intermediate shaft SE...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com