Heat flow calibration method for ground thermal intensity cabin test of aerospace plane

A technology of aerospace aircraft and calibration method, which is applied in the direction of aircraft component testing, aerodynamic testing, machine/structural component testing, etc. It can solve problems such as test errors, achieve improved heating accuracy, high degree of freedom, and accurate and effective assessment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

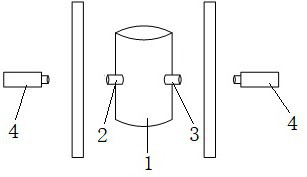

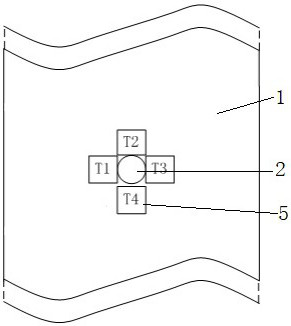

[0025] In order to make the implementation purpose, technical solutions and advantages of the present application clearer, the technical solutions in the embodiments of the present application will be described in more detail below with reference to the accompanying drawings in the embodiments of the present application.

[0026] A heat flow calibration method used for ground thermal strength cabin test of aerospace aircraft. The main factors affecting heat convection are: temperature difference, thermal conductivity and thickness and cross-sectional area of thermally conductive objects. The thermal conductivity is the objective physical quantity of the fluid. Therefore, the main simulation objects of this patent include temperature difference and thickness and cross-sectional area of thermally conductive objects.

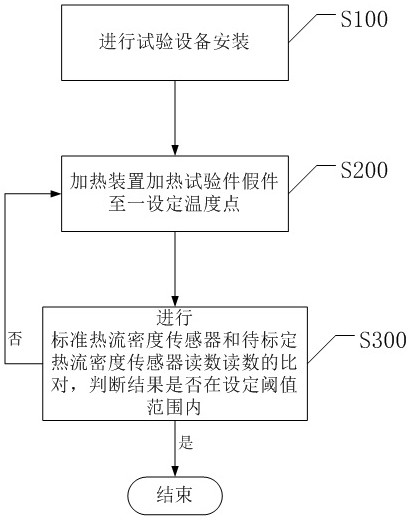

[0027] There are two kinds of heat flow calibration methods: absolute method and comparison method. The calibration method of this patent is the comparison met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com