Laser marking system

A laser marking and device box technology, applied in laser welding equipment, auxiliary welding equipment, welding equipment and other directions, can solve the problems of high and low temperature workpiece deformation, difficult to discharge, and reduce the quality of the workpiece, to improve quality, prevent offset printing, The effect of reducing the slight deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make it easy to understand the technical means, creation features, achieved goals and effects of the present invention, the present invention will be further described below with reference to the specific embodiments.

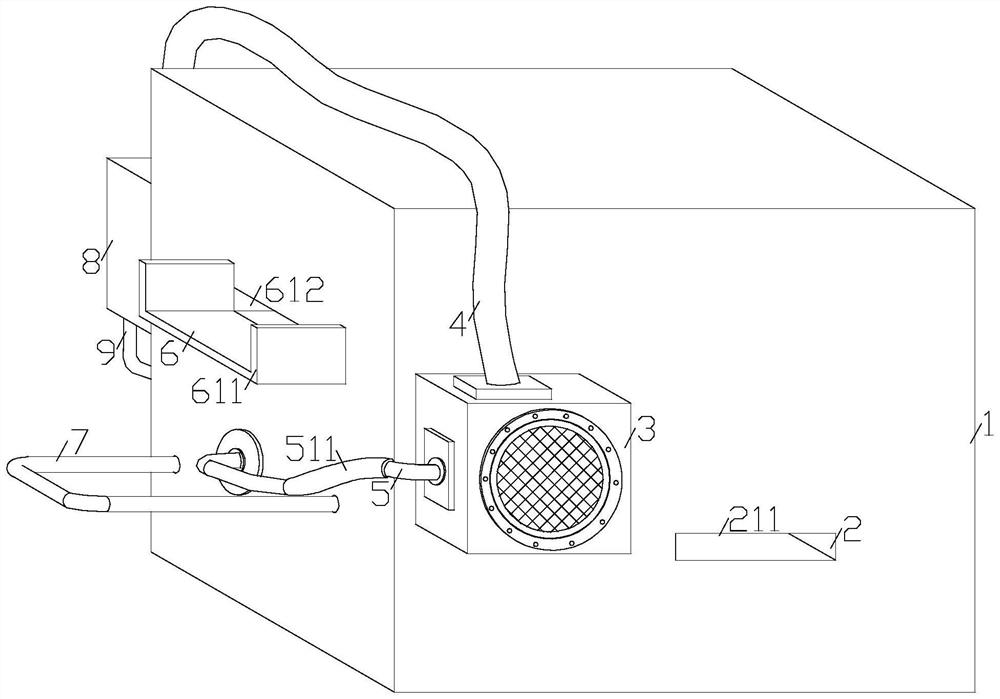

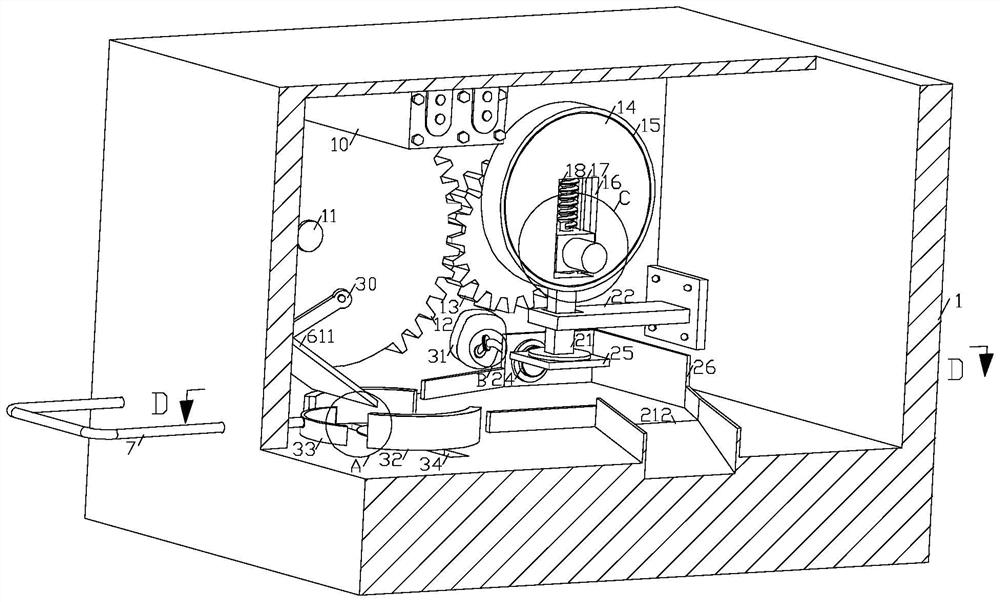

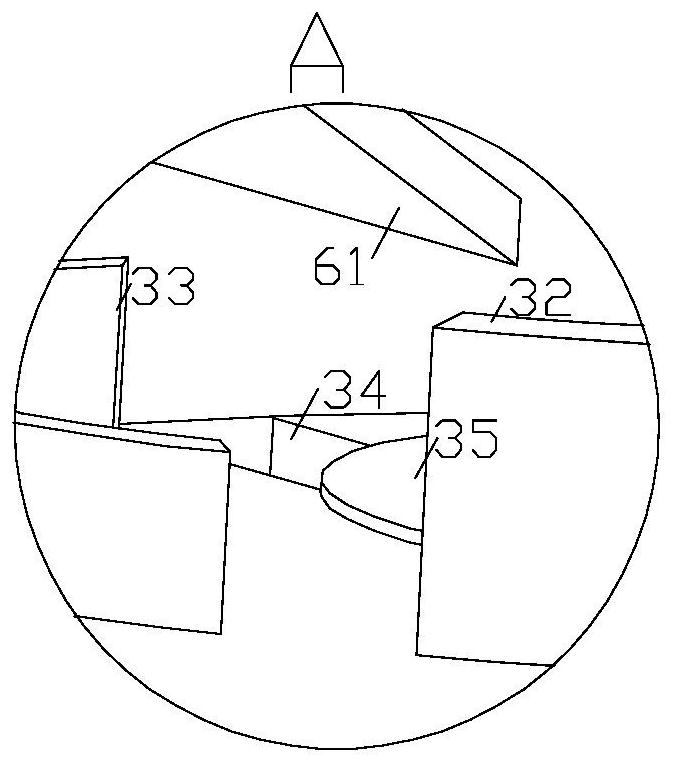

[0029] like Figure 1-Figure 7As shown in the figure, a laser marking system according to the present invention includes a device box 1, a fan 3 is fixedly installed on the front side of the device box 1, and a sealing box 8 is fixedly installed on the rear side of the device box 1, and a first fan 3 is fixedly installed on the left side of the fan 3 Two air pipes 5, a filter pipe 511 is fixed on the second air pipe 5, and the other end of the second air pipe 5 is connected to the left side of the device box 1, and the first air pipe 4 is fixedly installed on the upper end of the fan 3, and the first The other end of the gas transmission pipe 4 is connected to the upper side of the airtight box 8, and a wind wheel 29 is rotatably installed in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com