Paint spraying device with good environmental protection property for shipbuilding

An environmentally friendly and platform technology, applied in the direction of spraying device, spraying room, etc., can solve the problems of single spraying effect and single storage method, and achieve the effect of convenient cooling treatment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

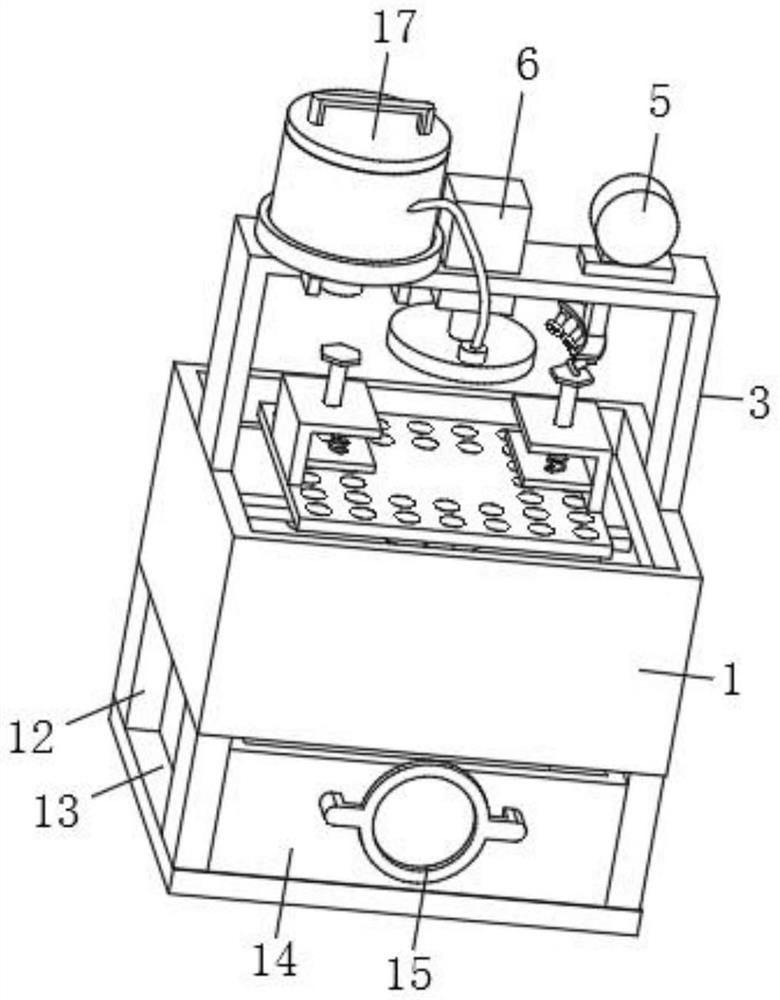

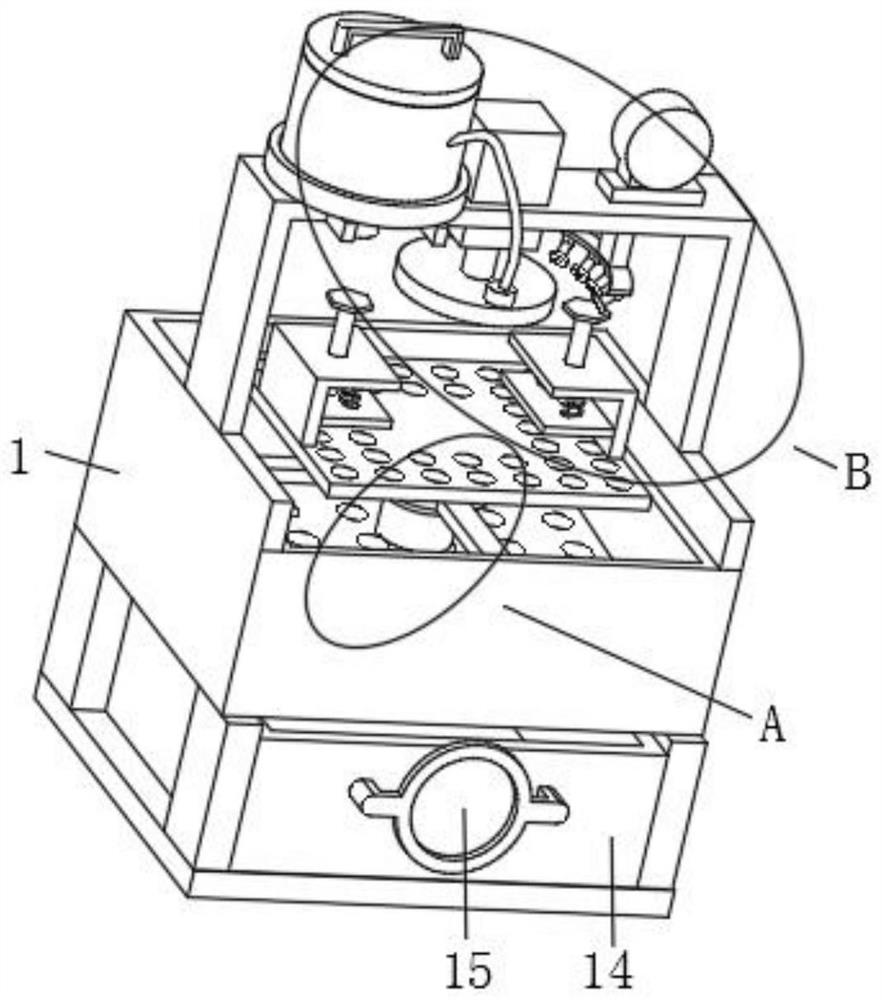

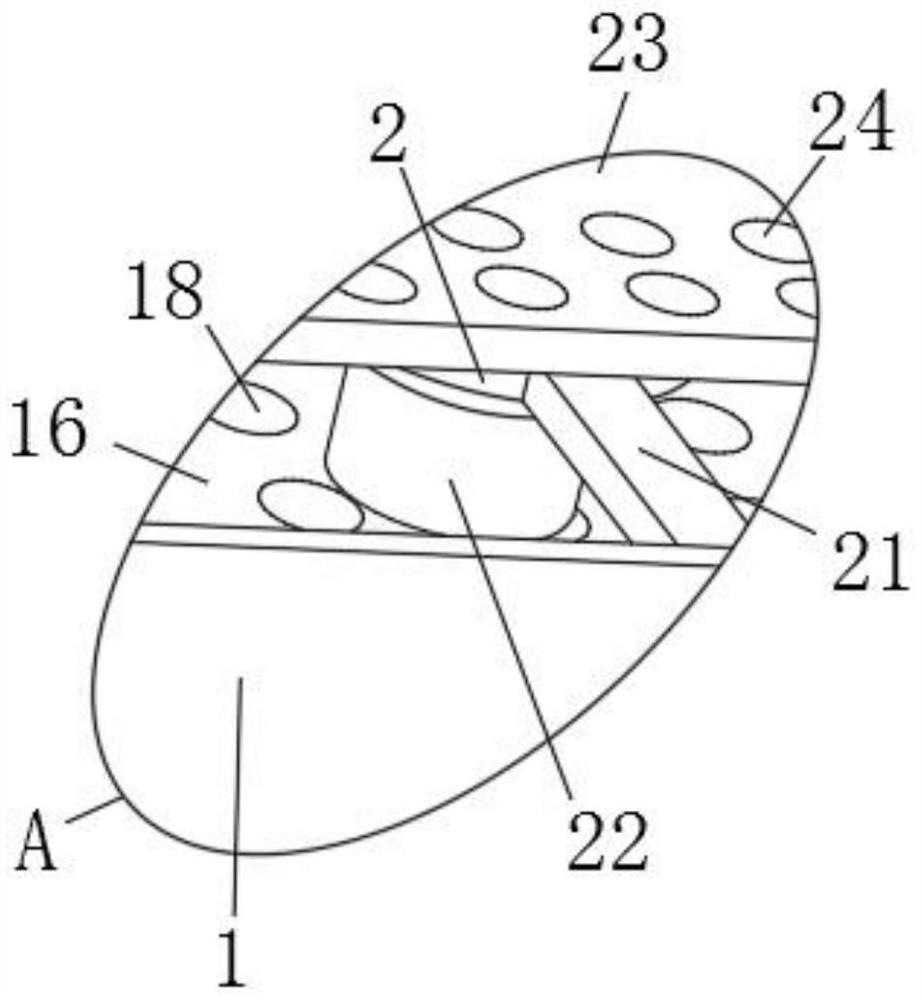

[0038] like Figure 1-Figure 5 As shown, a paint spraying device for shipbuilding with good environmental protection includes a paint spraying platform 1, and a rotating mechanism 2 is fixedly connected to the interior of the spraying platform 1. The rotating mechanism 2 is composed of a fixed frame 21, and the bottom of the fixed frame 21 is fixedly connected with a fixed motor 22, the fixed motor 22 is fixedly connected to the rotating platform 23 through the output end of the fixed frame 21, the interior of the rotating platform 23 is provided with a drain groove 24, the top of the painting platform 1 is fixedly connected with the top frame 3, and the top of the rotating platform 23 is fixedly connected There is a clamping mechanism 4. The clamping mechanism 4 is composed of a clamping frame 41. A pulling rod 42 is movably connected inside the clamping frame 41. The pulling rod 42 passes through one end of the clamping frame 41 and is fixedly connected to a clamping plate 43...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com