Dangerous chemical gas monitoring method based on NB-IOT (Narrow Band Internet of Things) technology

A gas monitoring and gas technology, which is applied in the field of hazardous gas monitoring based on NB-IOT technology, can solve the problems of low gas recognition rate and inaccurate detection results, and achieve inaccurate detection results, strong operability, and wide application overlay effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0081] It should be noted that the embodiments in the present application and the features in the embodiments may be combined with each other without conflict, and the present application will be further described in detail below with reference to the accompanying drawings and specific embodiments.

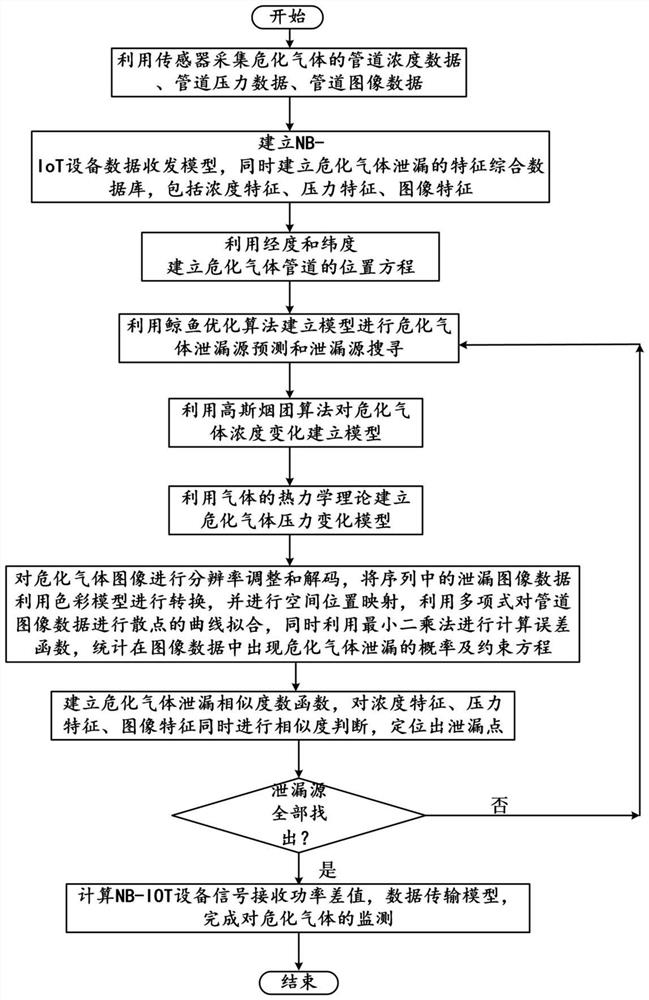

[0082] like figure 1 As shown, a hazardous gas monitoring method based on NB-IOT technology,

[0083] Step S1: Use a concentration sensor, a pressure sensor, and an image sensor to collect pipeline concentration data, pipeline pressure data, and pipeline image data of hazardous gas; the concentration sensor adopts a GC310 composite gas detector, and the pressure sensor adopts a CYYZ18 explosion-proof type The AcutEye used in the pressure transmitter and image sensor is a multi-target synchronous high-speed camera;

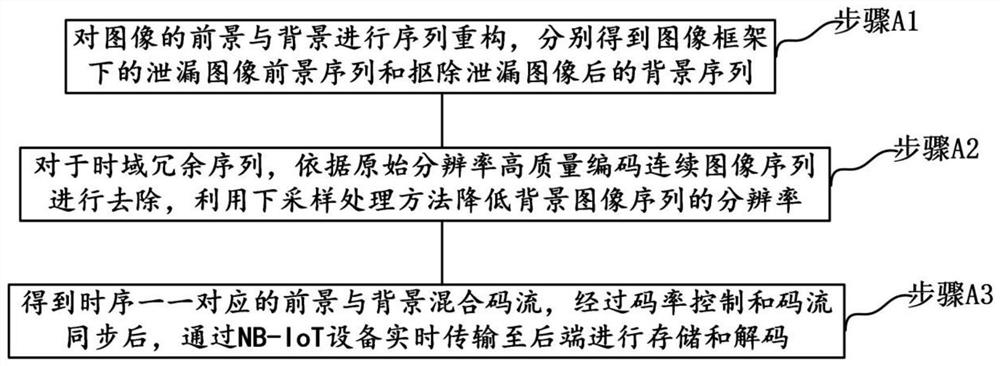

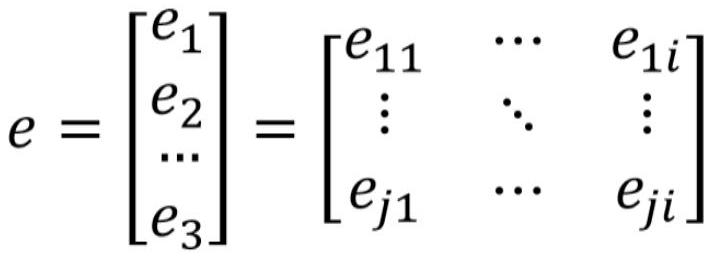

[0084] Step S2: Establish the NB-IoT device data sending and receiving model, and establish a comprehensive database of characteristics of hazardous gas leakage, incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com