Christmas tree with calibration function for oil field

A Christmas tree and functional technology, applied in the field of oil exploration, can solve the problems of not being able to directly detect the current viscosity of the fluid and the reduction of fluid accuracy, and achieve the effects of precise temperature rise and viscosity reduction control, flow performance improvement, and accuracy improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

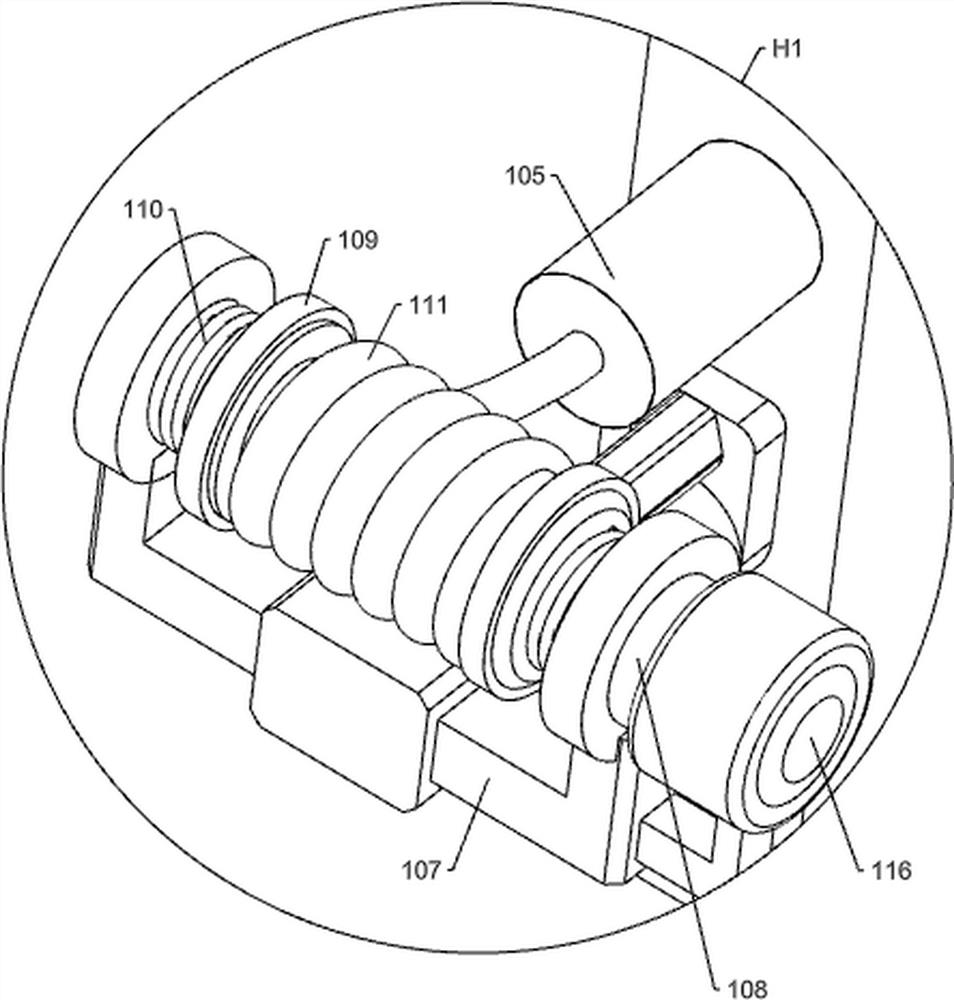

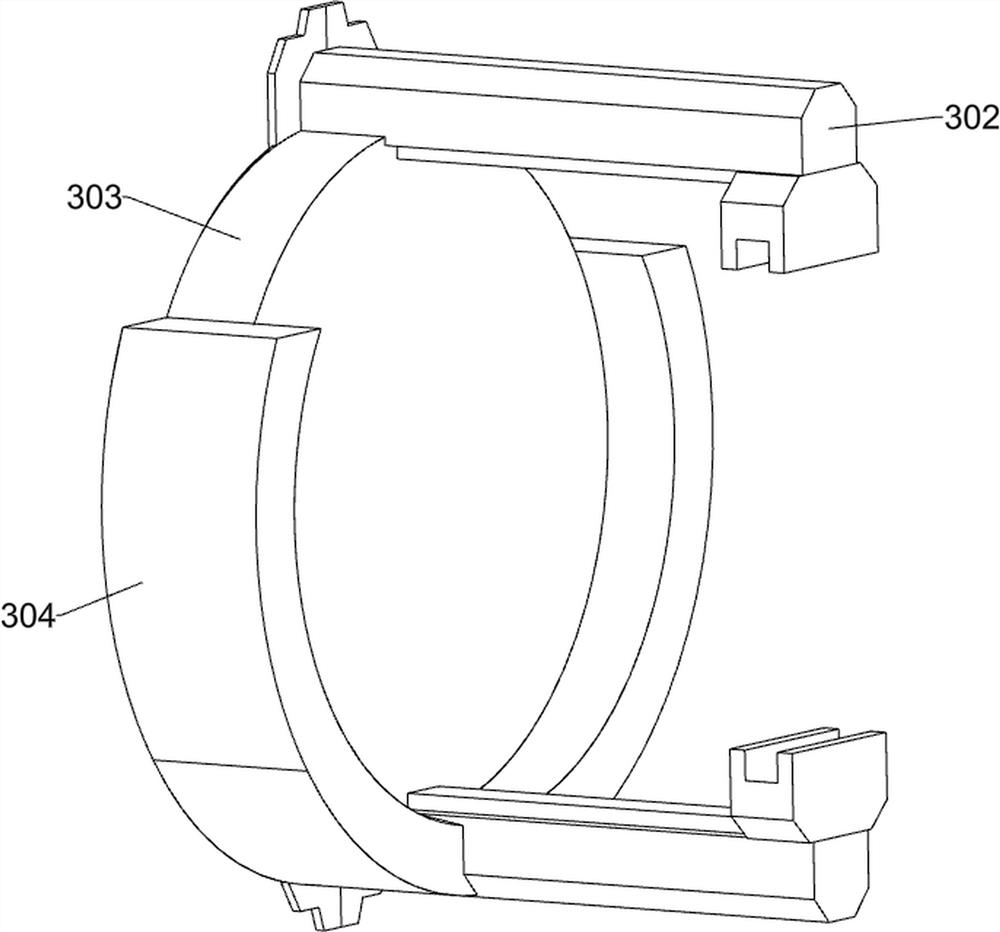

[0034] A kind of Christmas tree with calibration function for oil field, such as Figure 1-Figure 12 As shown, it includes a floating plate type viscosity monitoring unit, a heating unit, a viscosity correction unit, a Christmas tree body 1, a support pipeline 2, an oil pumping pipeline 3 and a monitoring pipeline 4; the Christmas tree body 1 is provided with a flowmeter for monitoring fluid flow; The lower end of the Christmas tree body 1 is connected with a support pipeline 2; the lower end of the support pipeline 2 is connected with an oil pumping pipeline 3; the inner side of the support pipeline 2 is connected with a monitoring pipeline 4; the monitoring pipeline 4 is connected with the oil pumping pipeline 3; A lower through groove 3a is reserved between the upper side of the oil pipeline 3 and the support pipeline 2; the inner side of the oil pumping pipeline 3 is provided with a number of thread grooves 3b; an upper part is reserved between the upper side of the monitor...

Embodiment 2

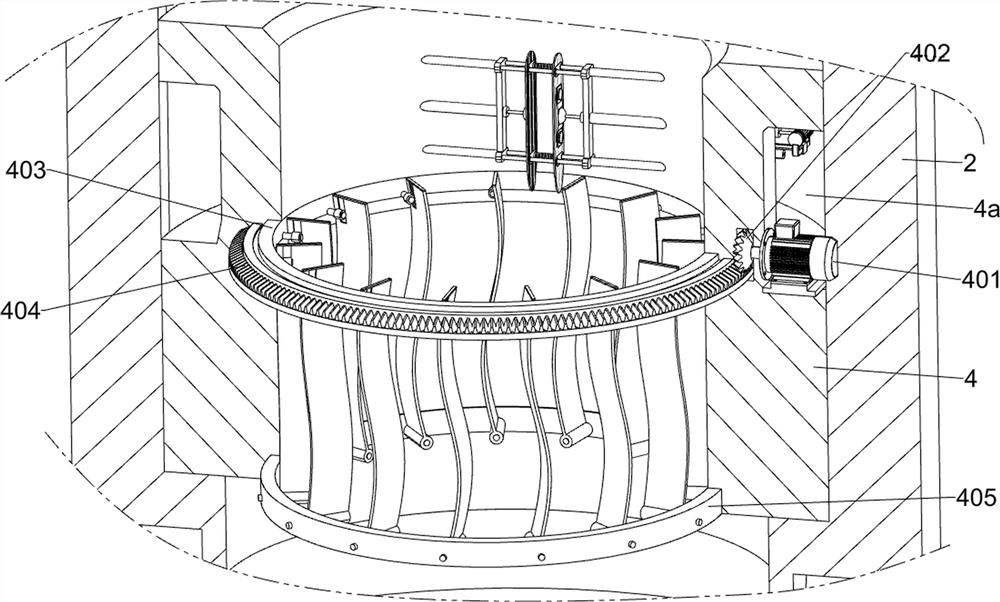

[0049] This embodiment is further optimized on the basis of Embodiment 1, such as Figure 1-Figure 15 As shown, it also includes a flow stabilizing unit, and the monitoring pipeline 4 is provided with a flow stabilizing unit. The flow stabilizing unit includes a drive motor 401, a bevel gear 402, an annular slider 403, an annular bevel tooth plate 404, an annular fixed plate 405, a guide The flow plate 406 and the second slider 407; the right side of the upper through groove 4a of the monitoring pipe 4 is bolted with the driving motor 401; the output shaft of the driving motor 401 runs through the inner and outer sides of the monitoring pipe 4; the left end of the output shaft of the driving motor 401 is fixed The bevel gear 402 is connected; the upper part of the inner side of the monitoring pipeline 4 is slidably connected with an annular slider 403; the outer surface of the annular slider 403 is fixed with an annular bevel tooth plate 404; the annular bevel tooth plate 404 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com