Sludge dewatering method adopting low-pressure hot air segmentation type filter pressing and purging

A technology of sludge dehydration and hot air, applied in water/sludge/sewage treatment, sludge treatment, chemical instruments and methods, etc., can solve the problems of high energy consumption, limited dehydration effect, high auxiliary cost of conditioner, etc. Low cost, reduced production cost, and easy recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1 A kind of sludge dewatering method of low pressure hot air split type filter press purging

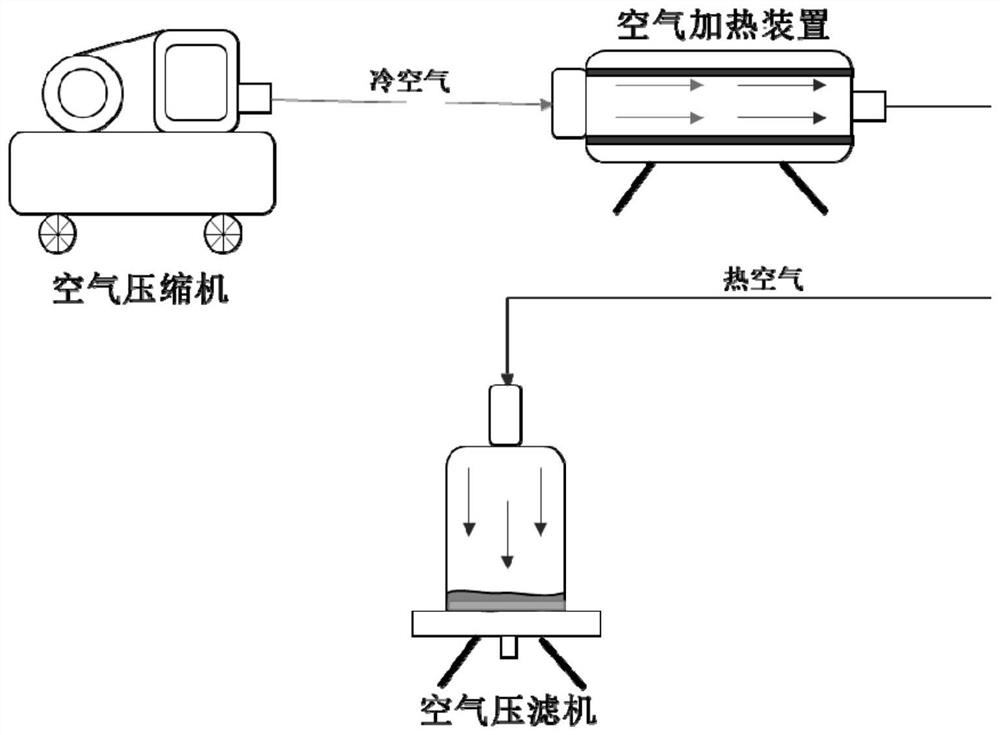

[0029] The sludge dewatering method of the low-pressure hot air split type filter press purging comprises the following steps (see the schematic diagram for the process flow). figure 1 ):

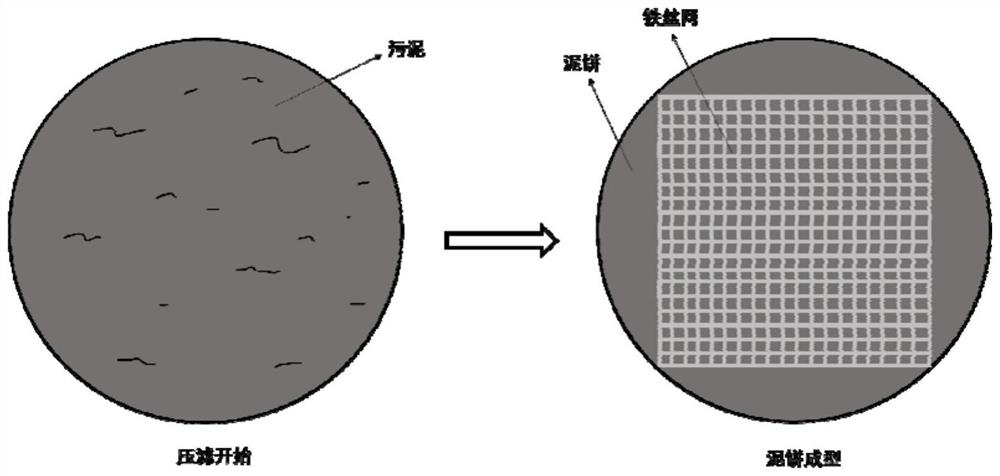

[0030] S1. Place a wire mesh with a diameter of 7 mm, a number of holes of 75, and a wire meridian of 1.25 mm on the filter cloth, and pour 100g of uniformly stirred sludge into the filter press;

[0031] S2. Turn on the air compressor, adjust the valve, keep the air pressure in the filter press at 0.6MPa, and start filtering the sludge;

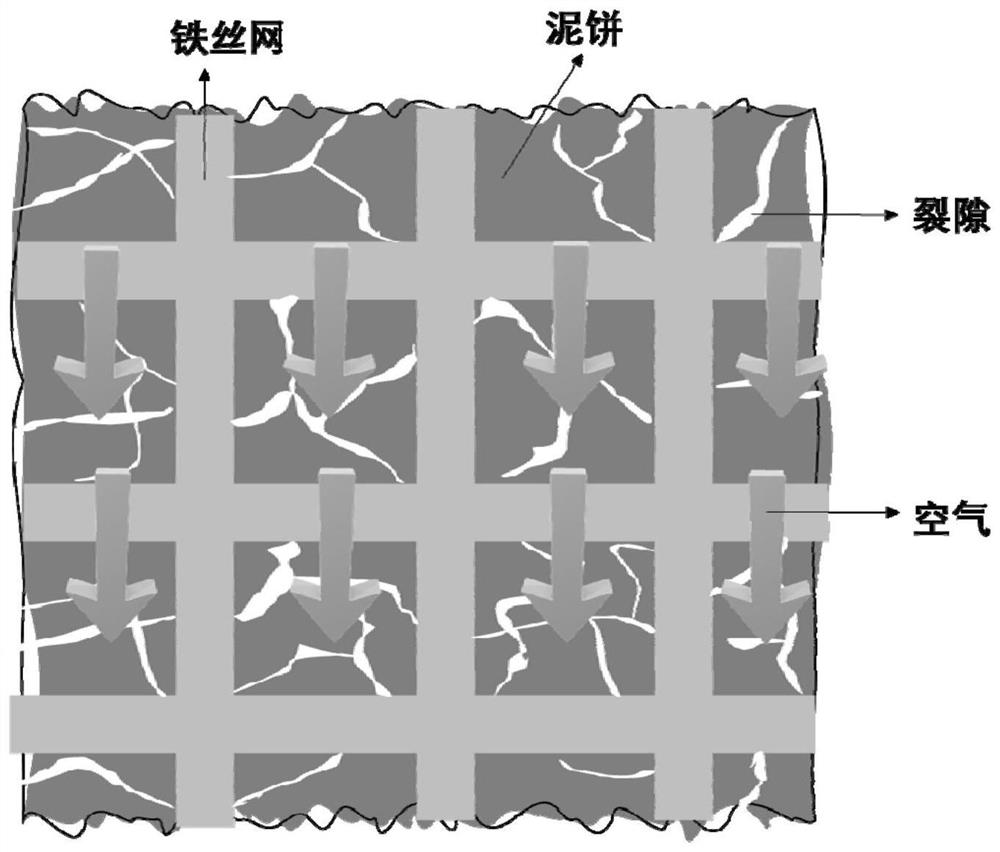

[0032] S3. When the pressure in the filter press drops rapidly, it means that there are many cracks formed on the sludge filter cake (see the schematic diagram of sludge dewatering). figure 2 ), turn on the air heating device at this time, set the temperature to 35 ° C, close all devices after 60 min, and take out the mud cake (see the schem...

Embodiment 2

[0035] Embodiment 2 A kind of sludge dewatering method of low pressure hot air split type filter press purging

[0036] The sludge dewatering method of the low-pressure hot air split type filter press purging comprises the following steps:

[0037] S1. Place a wire mesh with a pore diameter of 4 mm, a number of holes of 225, and a wire meridian thickness of 0.8 mm on the filter cloth, and pour 100 g of uniformly stirred sludge into the filter press;

[0038] S2. Turn on the air compressor, adjust the valve, keep the air pressure in the filter press at 0.6MPa, and start filtering the sludge;

[0039] S3. When the pressure in the filter press drops rapidly, it means that there are many cracks formed on the sludge filter cake. At this time, turn on the air heating device, set the temperature to 35 °C, close all devices after 60 minutes, and take out the mud cake.

[0040] Refer to Example 1 for the evaluation of the effect of the sludge dewatering method.

[0041] In this examp...

Embodiment 3

[0042] Embodiment 3 A kind of sludge dewatering method of low pressure hot air split type filter press purging

[0043] The sludge dewatering method of the low-pressure hot air split type filter press purging comprises the following steps:

[0044] S1. Place a wire mesh with a diameter of 6 mm, a number of holes of 100, and a wire meridian of 1.25 mm on the filter cloth, and pour 100 g of uniformly stirred sludge into the filter press;

[0045] S2. Open the air compressor and adjust the valve to keep the air pressure in the filter press at 0.8MPa, and start filtering the sludge;

[0046] S3. When the pressure in the filter press drops rapidly, it means that there are many cracks formed on the sludge filter cake. At this time, turn on the air heating device, set the temperature to 35 °C, close all devices after 60 minutes, and take out the mud cake.

[0047] Refer to Example 1 for the evaluation of the effect of the sludge dewatering method.

[0048] In this example, T 0 It ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com