Rotary table based on zero point positioning and application thereof

A technology of rotary table and zero-point positioning, applied in manufacturing tools, metal processing equipment, large fixed members, etc., can solve problems such as troublesome external pipelines and difficulties in exchangeable table, so as to improve efficiency, reduce labor intensity, Quick Swap Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

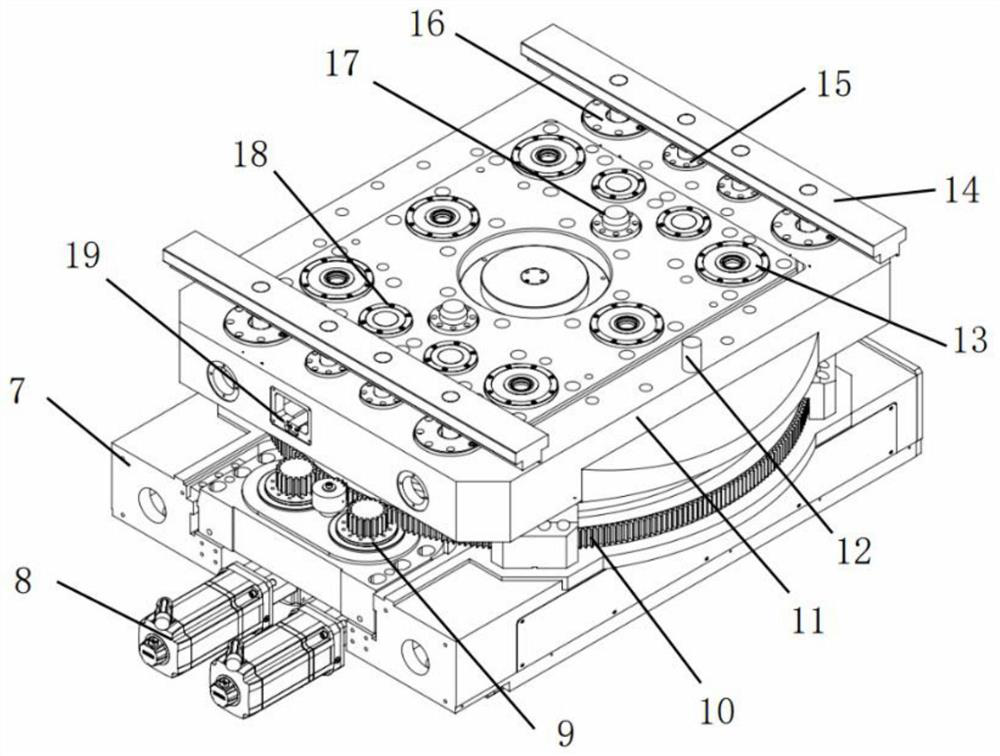

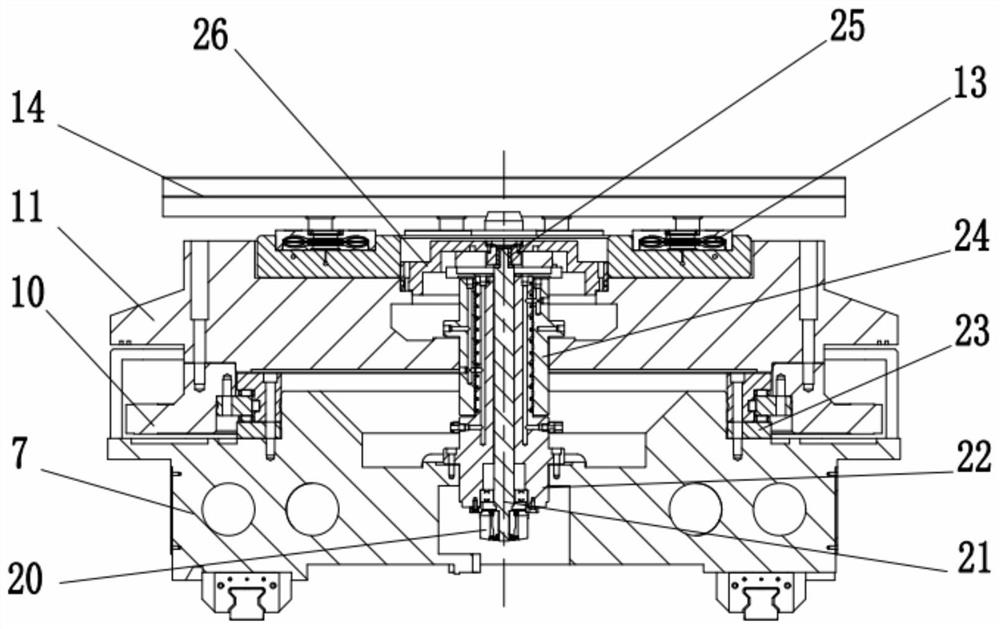

[0028] like Figure 1-3 As shown, a rotary table based on zero-point positioning includes a sliding seat 7, a rotary seat 11, a table board, a T-shaped guide rail 14, a rotary table bearing 23, a rotation control mechanism, a lifting control mechanism and a locking mechanism. The seat 11 is rotatably connected to the sliding seat 7 through a turntable bearing 23, two T-shaped guide rails 14 are symmetrically arranged on the upper end face of the turning seat 11, and two T-shaped guide grooves are arranged on the lower end face of the worktable, so The worktable is installed on the T-shaped guide rail 14 through the T-shaped guide groove; the upper end surface of the rotary seat 11 is provided with six zero-point positioning master disks 13, and the six zero-point positioning master disks 13 are distributed symmetrically in two rows; There are six zero-point positioning male heads 27 on the lower end surface of the worktable, and the zero-point positioning male heads 27 corresp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com