Optical device production, processing and packaging device and packaging method thereof

A technology for packaging devices and optical devices, applied in the coupling of optical waveguides, etc., can solve the problems of increased labor intensity, inconvenient clamping and packaging of anti-drop nets, and easy sliding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The following description serves to disclose the invention to enable those skilled in the art to practice the invention. The preferred embodiments described below are given by way of example only, and other obvious modifications will occur to those skilled in the art.

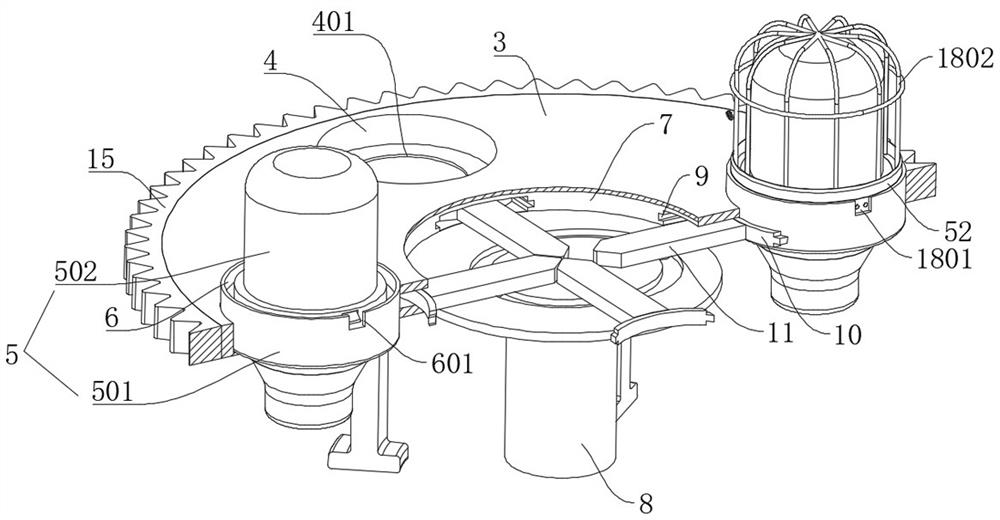

[0038] like Figure 2 to Figure 12 The shown optical device production, processing and packaging device includes a bottom plate 1 and a second circular plate 13. The top of the bottom plate 1 is slidably connected with four sliders 2, and the tops of the four sliders 2 are jointly and fixedly connected with a first circular plate. 3, is characterized in that, the top of the first circular plate 3 is provided with four first placement slots 4 in a circular array, the inner bottom of the first placement slot 4 is provided with a first through port 401, and the first placement slot 4 is inserted with Explosion-proof lamp 5. The explosion-proof lamp 5 is composed of a lamp holder 501 and a bulb 502 that are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com