Telescopic device of building highway bridge guardrail

A technology for highway bridges and telescopic devices, which is applied in construction, bridges, bridge construction, etc., can solve the problems of troublesome use, inconvenient operation and use, time-consuming and laborious, etc., and achieves convenient use, enhanced support stability, and convenient and time-saving use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, but not all of the embodiments.

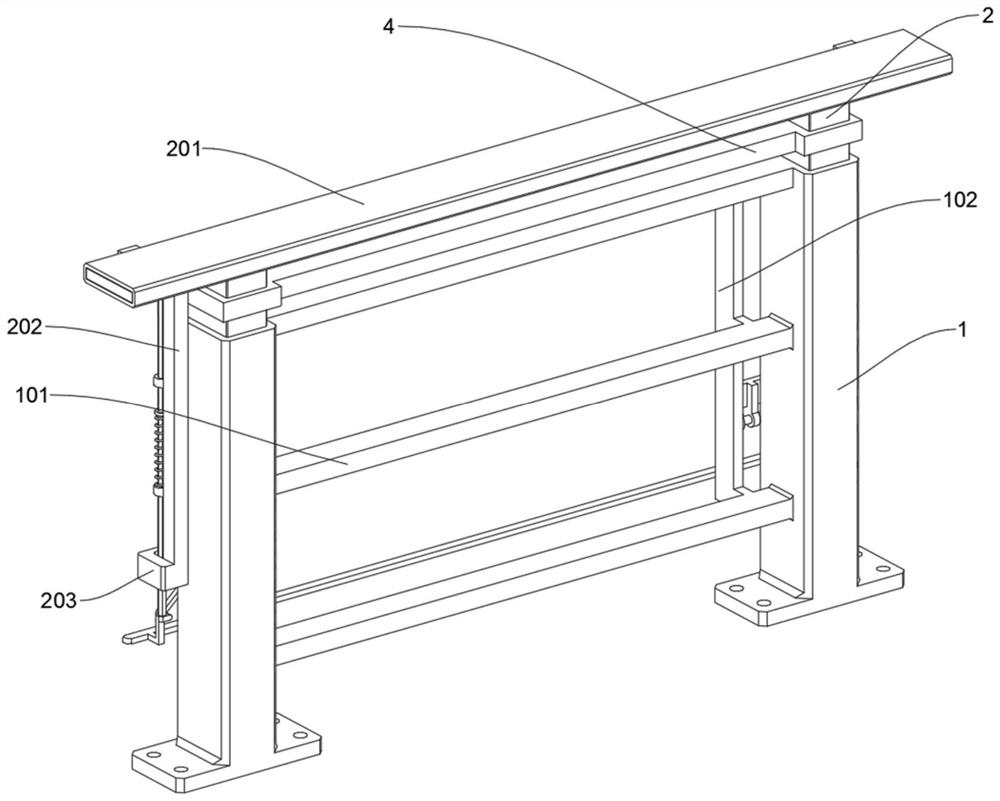

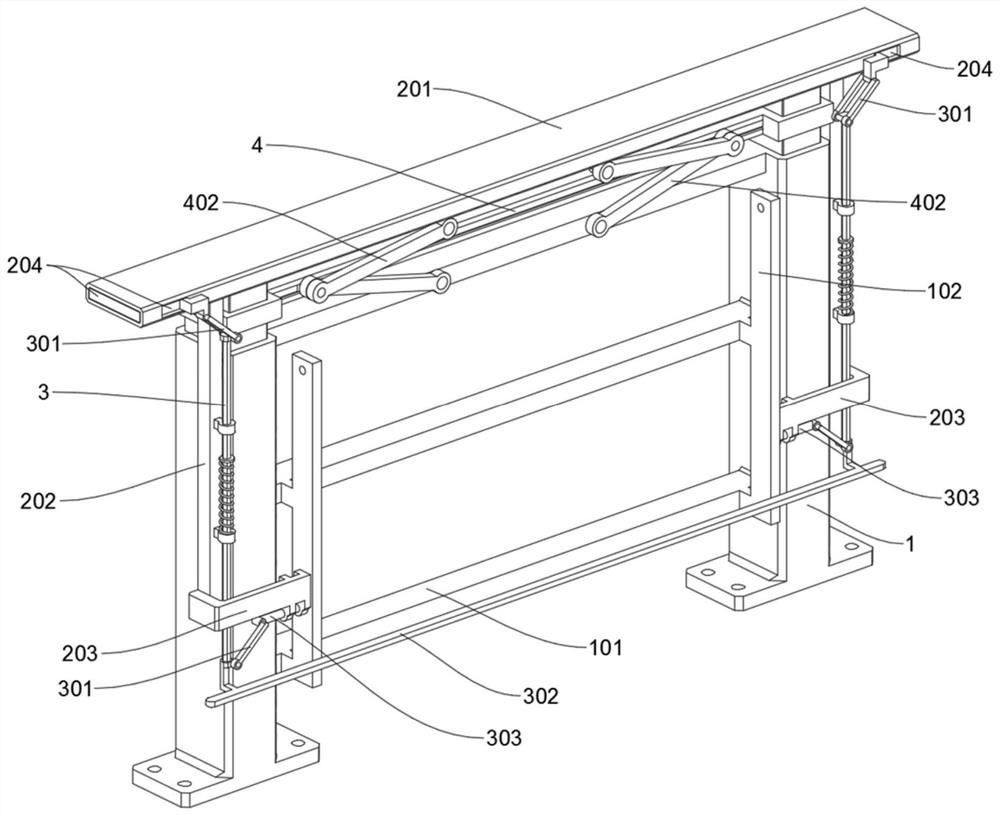

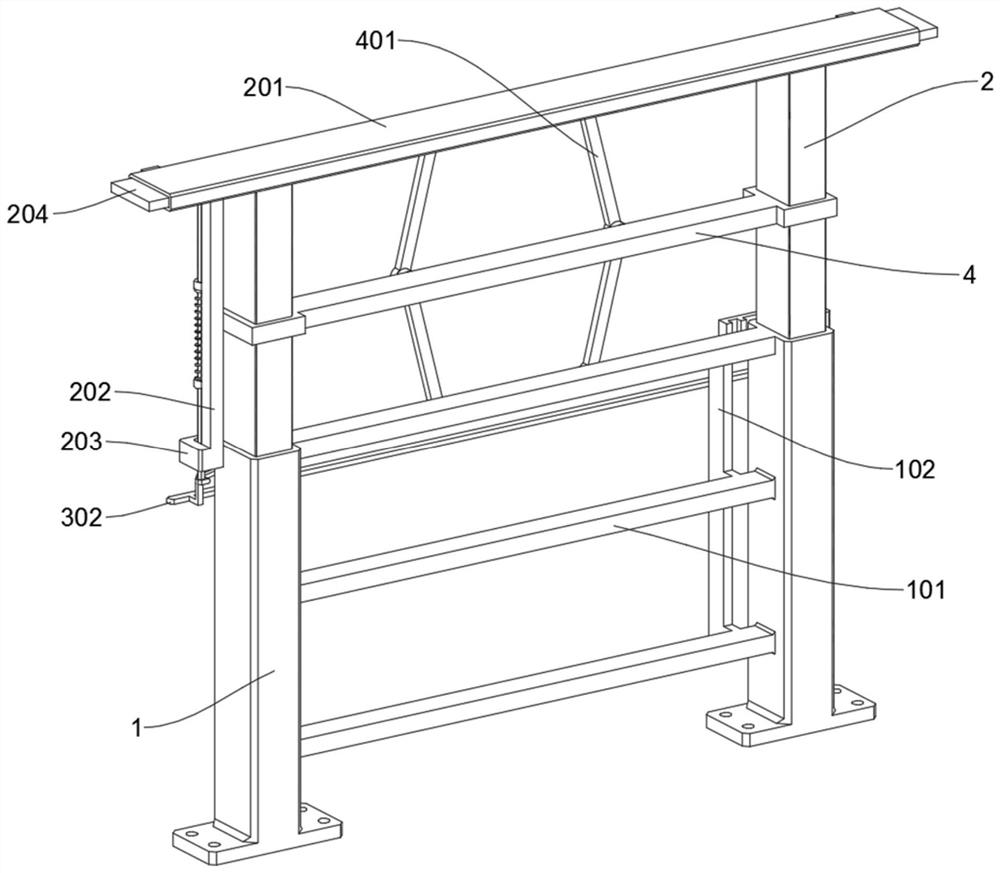

[0026] see Figure 1 to Figure 10 ;

[0027] The present invention proposes a telescopic device for building a highway bridge guardrail, comprising: a ground contact support portion 1; the ground contact support portion 1 includes a transverse support connection pipe 101, and the ground contact support portion 1 is integrally supported by two vertical support square pipes on the left and right. and three horizontal bracing connection pipes 101 welded between two vertical bracing square pipes at equal distances up and down. The bottom of the head end of the plate 203 is welded with two lifting rings at intervals, the two positioning rods 30...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com