Variable-speed constant-frequency power generation system

A technology of constant frequency power generation and generator, applied in wind power generation, electromechanical devices, electrical components, etc., can solve the problems of inconvenient exciter disassembly and exciter maintenance, and achieve the effect of easy fixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

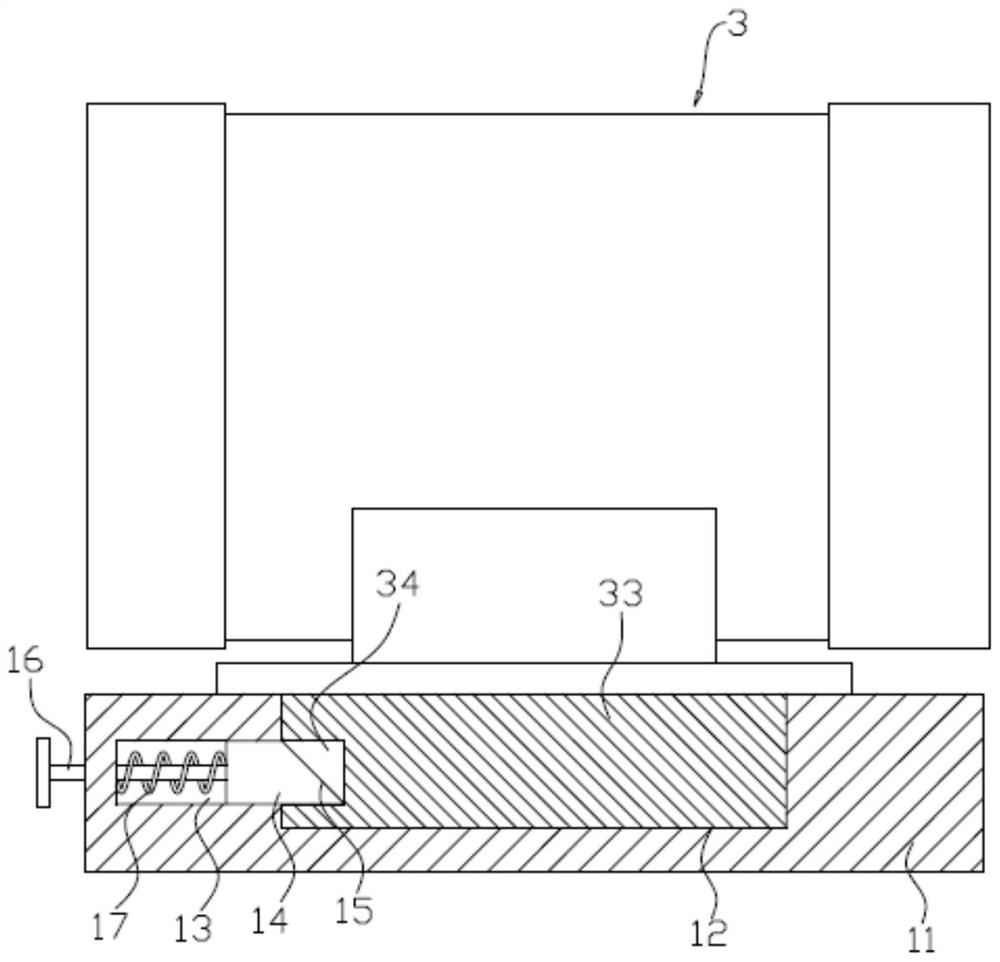

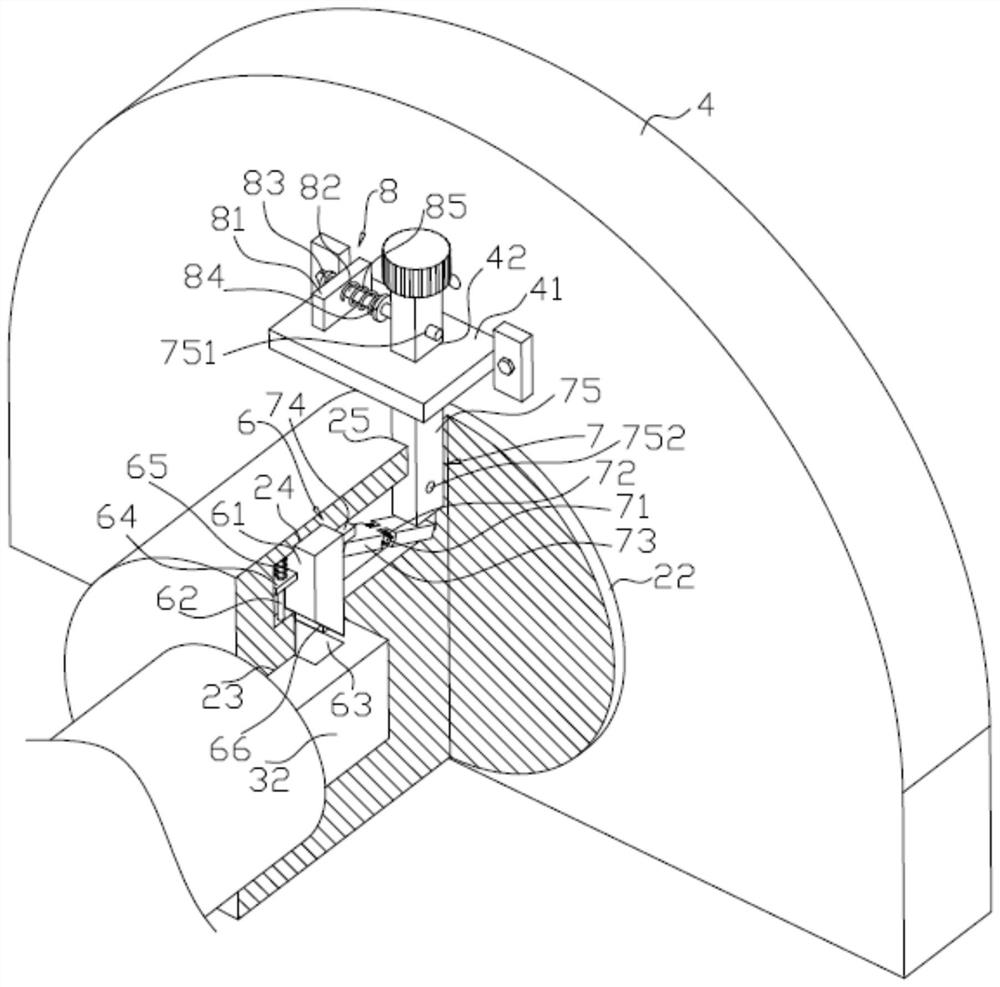

[0032] A variable speed constant frequency power generation system, such as figure 1 As shown, it includes a frame 1, a generator 2 installed on the frame 1, and an exciter 3 installed on the frame 1. A connecting frame 4 is installed on the top of the frame 1. The generator 2 includes a first rotating shaft 21, and the exciter 3 includes a second rotating shaft 31, the first rotating shaft 21 and the second rotating shaft 31 are coaxial.

[0033] like figure 1 and figure 2 As shown, one end of the first rotating shaft 21 close to the second rotating shaft 31 is fixed with a connecting block 22, the connecting block 22 is cylindrical, the connecting block 22 is connected to the connecting frame 4 through the bearing rotation, and the top of the frame 1 slides along its length direction. A moving plate 11 is connected to the moving plate, the exciter 3 is detachably connected to the moving plate 11, and a driving mechanism 5 for driving the moving plate 11 to move is install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com