Fixing part used for fixing electromagnetic valve and provided with protection structure

A protective structure and solenoid valve technology, applied in the field of solenoid valves, can solve the problems of affecting the service life of the device, incapable of solenoid valve protection, line wear, etc., and achieve the effects of facilitating maintenance and detection, avoiding short circuits, and increasing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

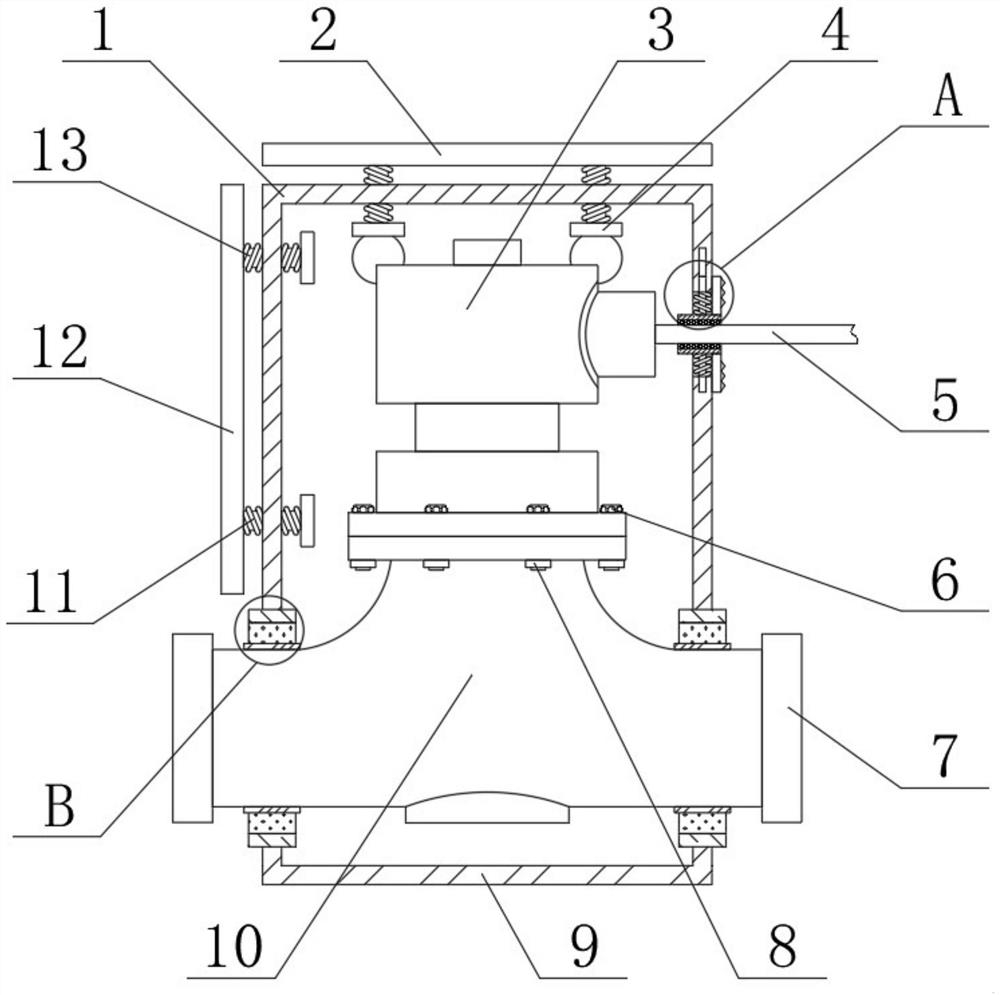

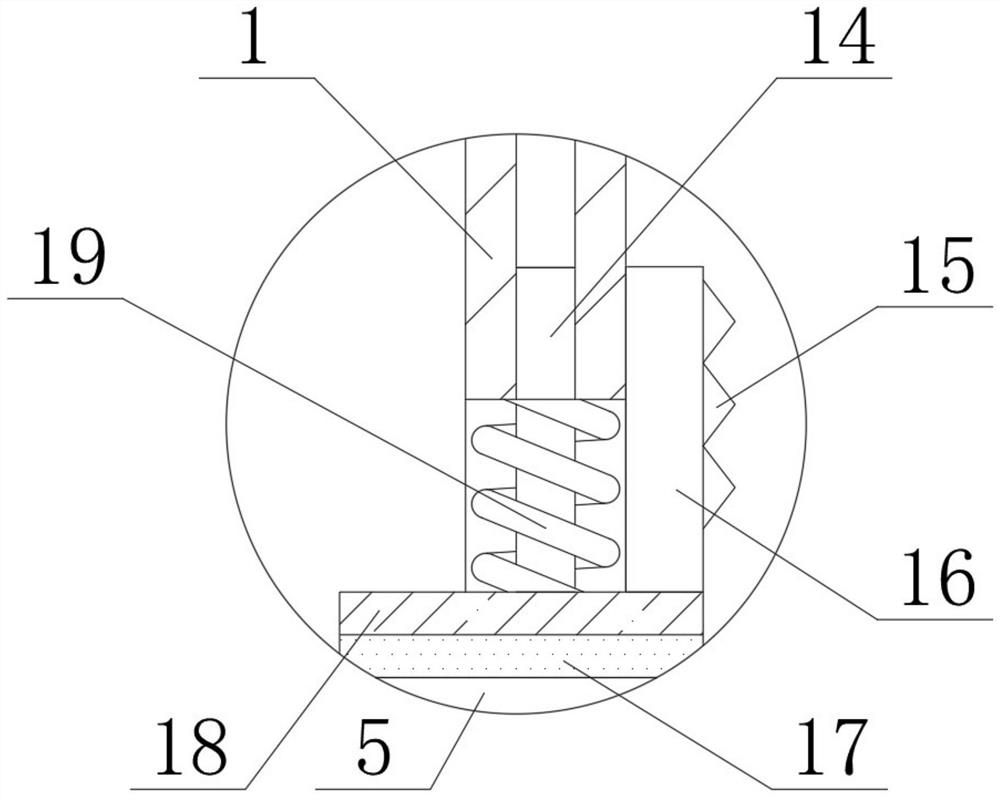

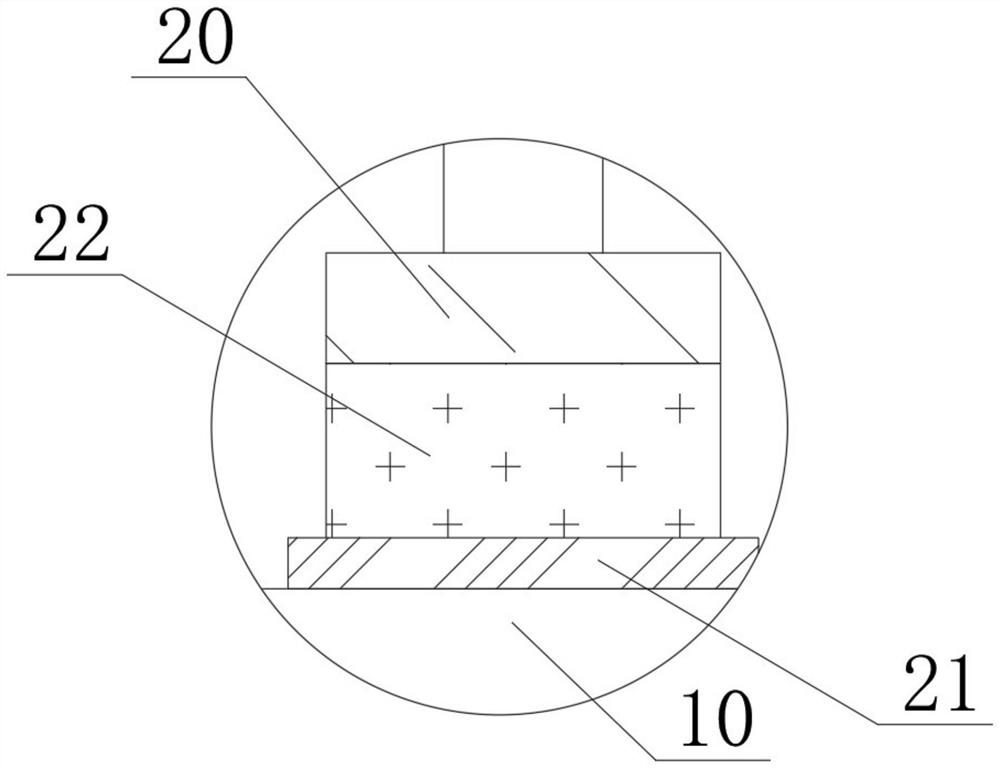

[0027] see Figure 1-5 , the present invention provides a kind of technical scheme:

[0028] A fixing piece with a protective structure for fixing a solenoid valve, comprising an upper protective cover 1, a lower protective cover 9 and a solenoid valve body 3, the solenoid valve body 3 is arranged in the upper protective cover 1, and the side of the upper protective cover 1 is provided with side guards Plate 12, the upper end of the upper protective cover 1 is provided with an upper protective plate 2, and one end of the upper protective plate 2 and the side protective plate 12 close to the upper protective cover 1 is provided with a limit rod 13, and the limit rod 13 passes through the upper protective cover 1. The protective cover 1 is slidably connected with the limit rod 13 . The limit rod 13 is provided with a fixing plate 4 at one end close to the solenoid valve body 3 . A spring 11, the first spring 11 is connected to the upper protective cover 1, the first spring 11 i...

Embodiment 2

[0032] see Image 6 , the present invention provides a kind of technical scheme:

[0033] Both ends of the upper connecting plate 23 are provided with fixing cavities 29. A threaded rod 30 is passed through the fixing cavity 29. The threaded rod 30 is rotatably connected to both ends of the lower connecting plate 24. The threaded rod 30 is screwed with a threaded sleeve 28. 28 is slidably connected to the upper connecting plate 23, and the upper protective cover 1 and the lower protective cover 9 can be easily disassembled and installed through the threaded rod 30 and the threaded sleeve 28.

[0034] Workflow: In Embodiment 2, the same parts as in Embodiment 1 will not be repeated, the difference is that when the upper protective cover 1 and the lower protective cover 9 are disassembled, the threaded sleeve 28 can be rotated to make the threaded sleeve 28 and the upper protective cover 9. The connecting plate 23 is separated, and then the threaded rod 30 is rotated. At this t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com