Rock cross-cut coal uncovering high-pressure air fracturing anti-reflection and outburst prevention effect evaluation method

A technology of high-pressure air and Shimen coal removal, which is applied in earthwork drilling, climate sustainability, and other gas emission reduction technologies, can solve problems such as high difficulty in implementation, impact on mine operation safety, and difficulty in obtaining evaluation parameters. Achieve the effect of improving the safety factor, strong applicability and high comprehensiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention. In addition, it should be noted that, for the convenience of description, the drawings only show some but not all structures related to the present invention.

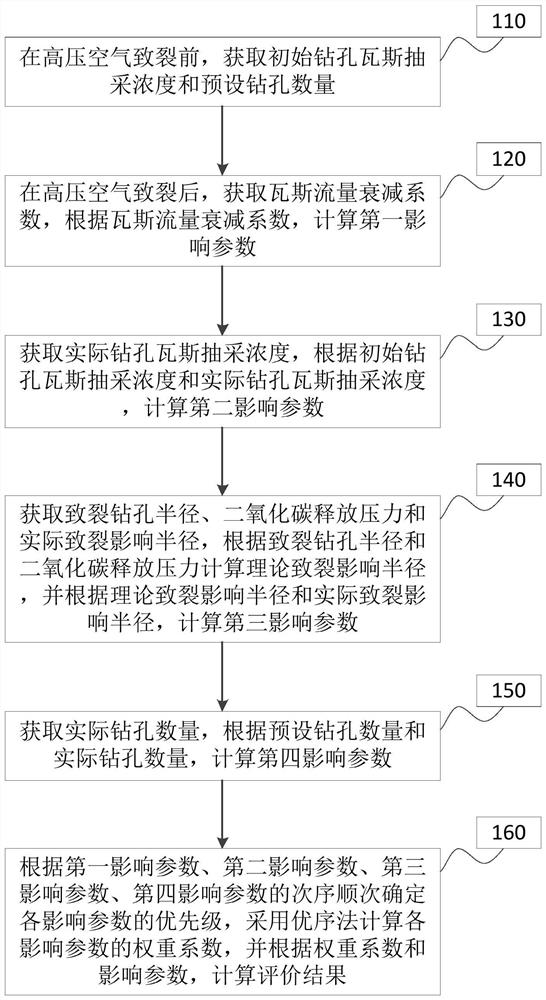

[0042] figure 1 The flow chart of the method for evaluating the effect of high-pressure air cracking and anti-outburst in Shimenjie coal provided by the embodiment of the present invention specifically includes the following steps:

[0043] Step 110: Before the high-pressure air cracks, obtain the initial borehole gas drainage concentration and the preset borehole quantity.

[0044] In the daily operation of the mine, it is necessary to drill holes in the coal seam and gas accumulation areas, and then install special pipelines on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com