Furnace baking method for large converter

A drying method and technology for large-scale converters, which are applied in the field of converter lining and smelting, can solve the problems of single baking method, poor adaptability, lack of dynamic monitoring and adjustment mechanism, etc., and achieve a good location, low cost, reliable real-time monitoring data Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

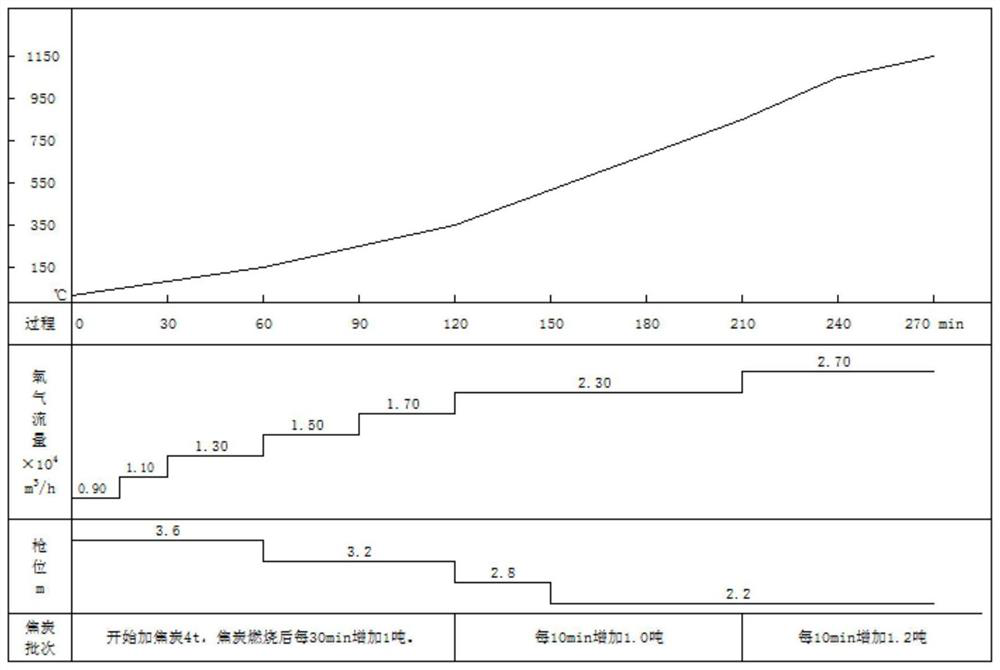

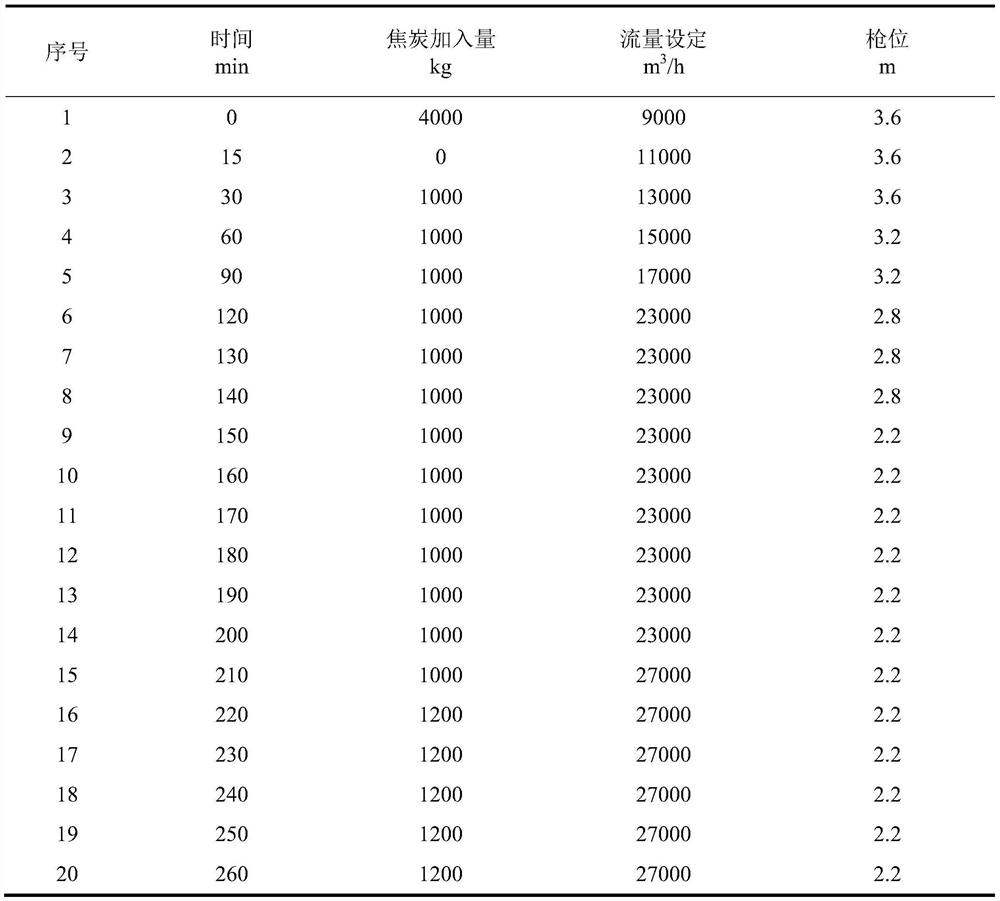

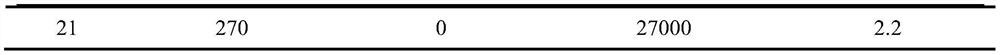

[0046] In the drying method of a large converter of this embodiment, the flow rate of the skirt cover water supply, the water outlet temperature, the flow rate of the oxygen, the sub-lance and the flux feeding water jacket, the outlet water temperature, and the pressure of the deaerator must be closely monitored during the oven, so as to quantify the The process gun position, flow rate, coke addition amount and timing are controlled. When one of the following conditions is met, the furnace operation will be suspended when the gun is lifted. After recovery, the gun lifting point will be connected for time accumulation (that is, the fault processing time will not be counted), and continue to follow Table 1. and figure 1 Perform related operations, including:

[0047] A1. The water supply flow rate of the skirt cover is less than or equal to 120t / h or the outlet water temperature of the skirt cover is greater than or equal to 150℃, and the duration is more than 60 seconds;

[00...

Embodiment 2

[0055] A method for drying a large-scale converter of the present embodiment, the basic structure is the same as that of Embodiment 1, and the difference and improvement are: a method for drying a 300-ton converter, which specifically includes the following steps:

[0056] Step 1. After the furnace is built, the converter is kept vertically locked, and the residual bricks and other debris in the furnace are cleaned up;

[0057] Step 2, before the moving skirt trolley is in place, put about 3 tons of dry and miscellaneous wood materials for the oven into the furnace from the furnace mouth;

[0058] Step 3. Start the fan, and start the dust-removing washing and spraying system once;

[0059] Step 4. Add 30kg of fuel oil from the oxygen lance hole to the surface of the dry and miscellaneous wood in the furnace, then ignite the fuel-impregnated cotton yarn or rag torch, and add it into the furnace from the oxygen lance hole to ignite the wood; the oxygen lance is manually operated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com