Automatic unlocking storage tool coiling trolley and self-locking structure

An automatic unlocking and tooling roll technology, which is applied in the direction of thin material processing, coiling strips, transportation and packaging, etc., can solve the problems of large quantity used, short storage length, large space occupation, etc., and achieve long storage length , reduce waste, and reduce the loss of coiling tooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

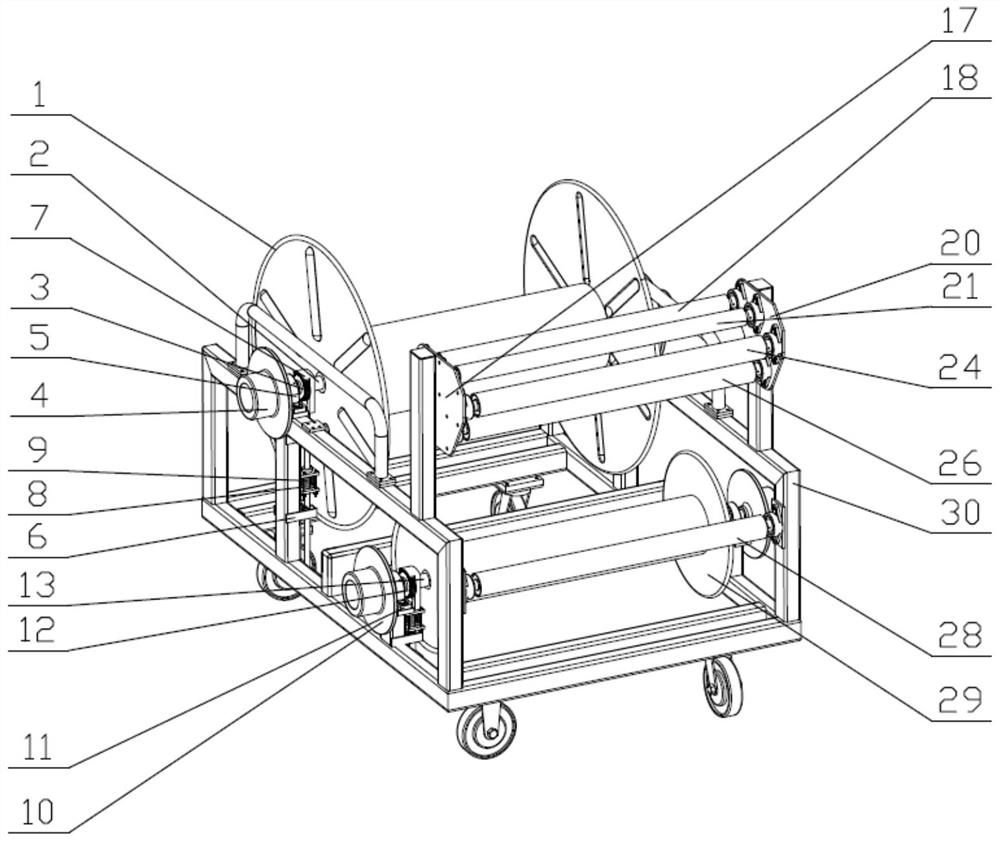

[0037] The embodiment of the present invention provides an automatic unlocking storage tooling and coiling trolley. The trolley includes a frame 30, a first transmission shaft 2 and a second transmission shaft 13, a large I-shaped wheel 1 and a small I-shaped wheel 29, and a first toothed disc. 3. The second chainring 12 , the first self-locking assembly 300 , the second self-locking assembly 600 , the connecting rod 200 and at least one driving motor (not shown);

[0038] The first transmission shaft 2 and the second transmission shaft 13 are respectively rotatably arranged on the vehicle frame 100, and they are arranged in parallel on the left and right sides of the vehicle frame 100, and the central axis of the first transmission shaft 2 is away from the vehicle. The height of the bottom side of the frame is greater than the central axis of the second transmission shaft 13, so that it is convenient to guide and unwind the coil.

[0039] The large I-shaped wheel 1 and the sm...

Embodiment 2

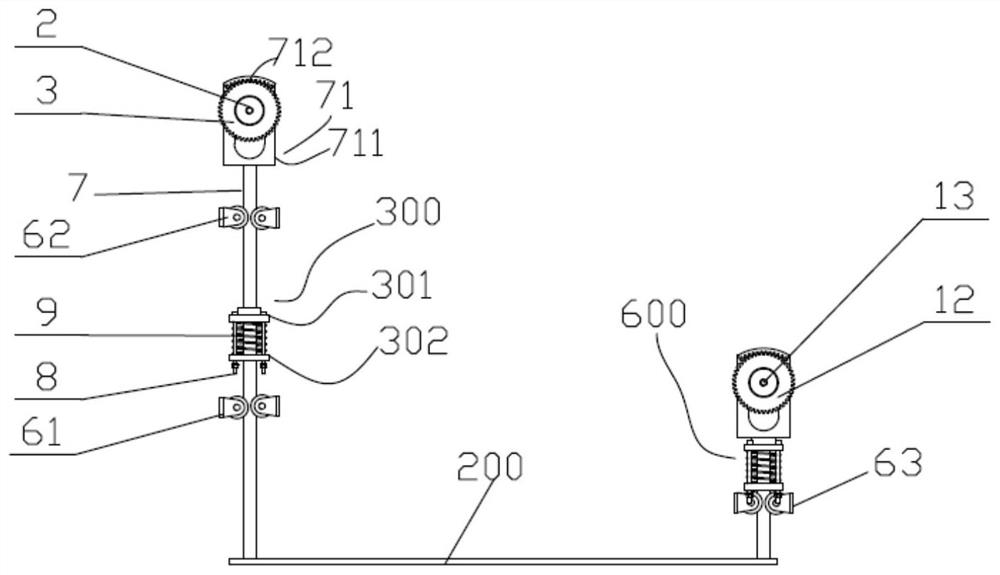

[0063] This embodiment provides a self-locking structure, which includes a first chainring 3, a second chainring 12, a first self-locking assembly 300, a second self-locking assembly 600, a connecting rod 200, and at least one driving motor. The disk 3 , the second toothed disk 12 , the first self-locking assembly 300 , the second self-locking assembly 600 , the connecting rod 200 and at least one driving motor adopt the structures described in Embodiment 1. The above self-locking structure can be widely used in the locking of transmission structures, and is very suitable for locking with two transmission structures (eg, transmission shafts).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com