Electric drive axle system and pure electric operation vehicle using same

A technology for operation and bridge driving, which is applied in the direction of electric vehicles, vehicle parts, electric power devices, etc., can solve the problems of scattered system layout and low degree of integration, and achieve the effects of compact system layout, improved transmission efficiency, and reduced power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

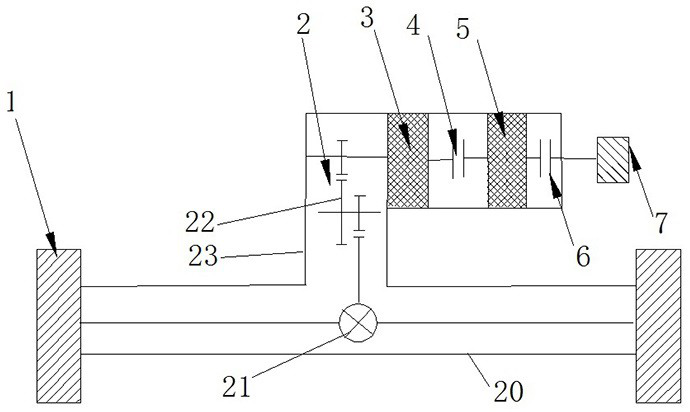

specific Embodiment 1

[0088] like figure 2 As shown, the electric drive axle system in this embodiment includes a vehicle axle 2, and the vehicle axle 2 is T-shaped as a whole, including a transverse axle portion 20 and a longitudinal axle portion 23, wherein the transverse axle portion 20 is along the left and right sides of the vehicle body. Extending in the width direction, the longitudinal axle portion 23 extends along the longitudinal direction of the front and rear of the vehicle body, and the wheels 1 are respectively mounted on both ends of the transverse axle portion 20 .

[0089] The axle 2 is provided with an axle main reducer 22 and an axle differential 21 , the axle main reducer 22 is located on the longitudinal axle part 23 , and the output end of the axle main reducer 22 is connected to the axle differential 21 . The power is input, and the axle differential 21 inputs the power to the wheels 1 on both sides through the semi-axes on both sides to drive the wheels 1 to rotate, and the...

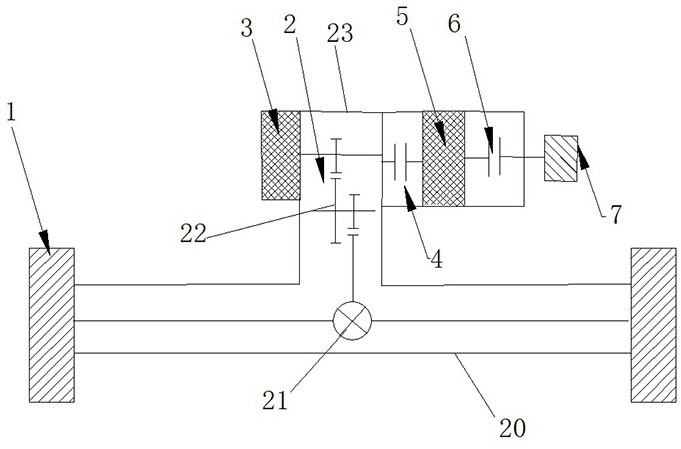

specific Embodiment 2

[0107] like image 3 As shown, the electric drive axle system in this embodiment also includes an axle 2, and the axle 2 is also T-shaped, and also has a transverse axle portion 20 and a longitudinal axle portion 23, wherein the transverse axle portion 20 is also along the vehicle axle. The body extends in the left and right width directions, the longitudinal axle portion 23 extends along the longitudinal direction of the vehicle body front and rear, and the wheels 1 are respectively mounted on both ends of the transverse axle portion 20 .

[0108] The axle main reducer 22 and the axle differential 21 are installed on the axle 2. The axle main reducer 22 is located in the longitudinal axle part 23 and is also a two-stage reducer. The axle differential 21 inputs power, and the axle differential 21 inputs the power to the wheels 1 on both sides through the two semiaxes, and drives the wheels 1 to rotate and drive the vehicle to run.

[0109] A drive motor 3 , a drive clutch 4 ,...

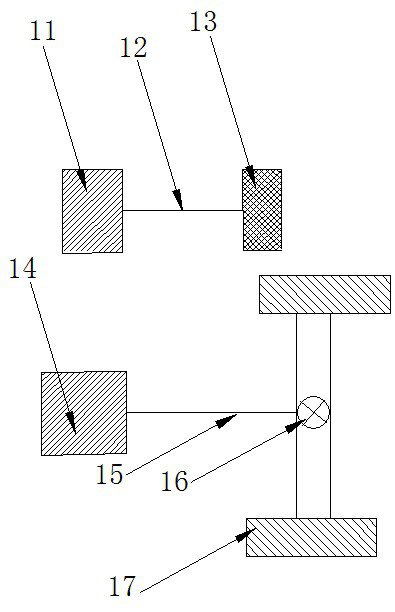

specific Embodiment 3

[0115] The main difference from Embodiment 1 is that in Embodiment 1, the two output shafts of the working motor are arranged coaxially, so that the driving clutch and the working clutch are correspondingly arranged on both sides of the working motor in the axial direction. In this embodiment, the two output shafts of the working motor are arranged vertically, and at this time, the positions of the driving clutch and the working clutch are also adjusted accordingly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com