Method for calculating fatigue life of belt type CVT steel belt ring under high rotating speed condition

A fatigue life and calculation method technology, applied in the field of metal belt CVT technology research, can solve the problems of easy fracture of steel belt rings, reduced reliability, and a large number of loads.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

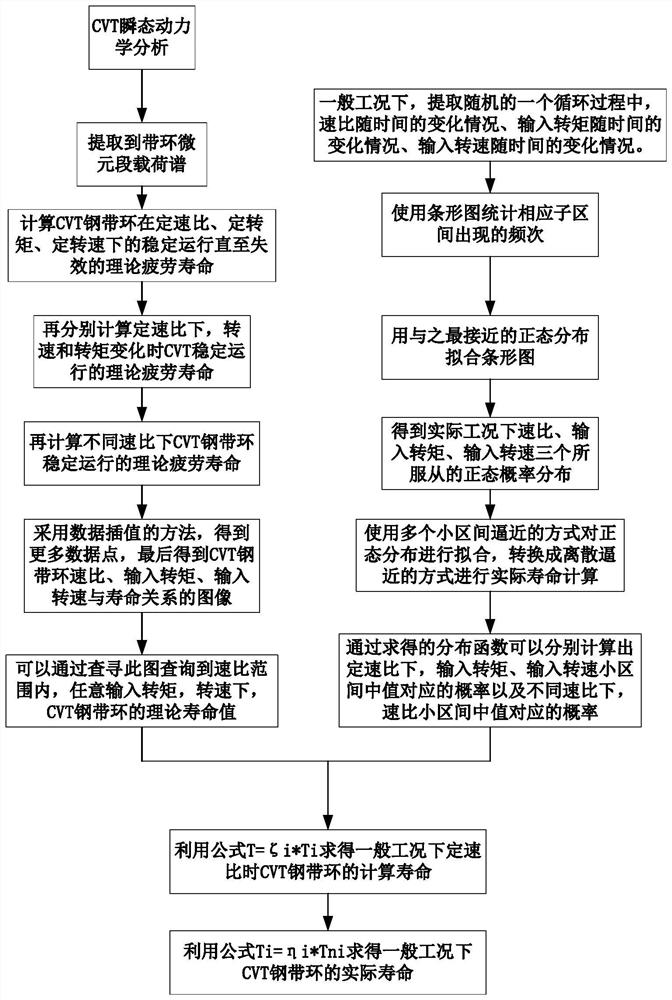

[0053] The present invention will be described in further detail below in conjunction with the accompanying drawings. The present invention adopts a calculation scheme such as figure 1 shown, the specific steps are as follows:

[0054] Step 1: Do the transient dynamic analysis of the belt CVT;

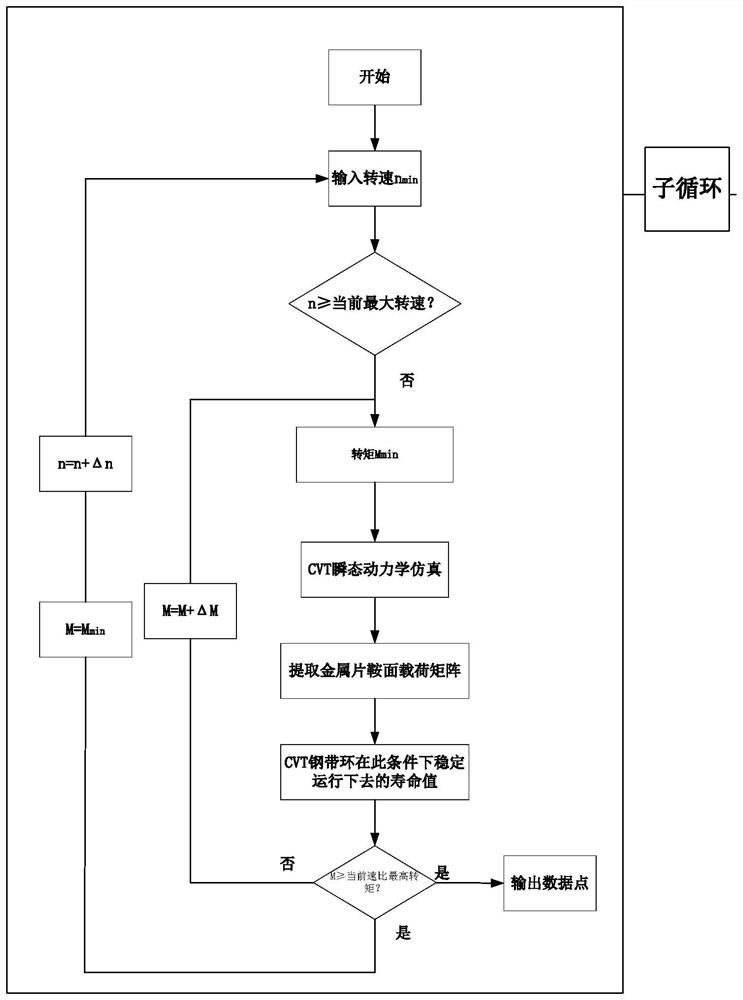

[0055] Step 2: Use the equivalent method to extract the load spectrum of the micro-element section of the steel belt ring for one week, and then calculate the fatigue life of the steel belt ring under the specified conditions;

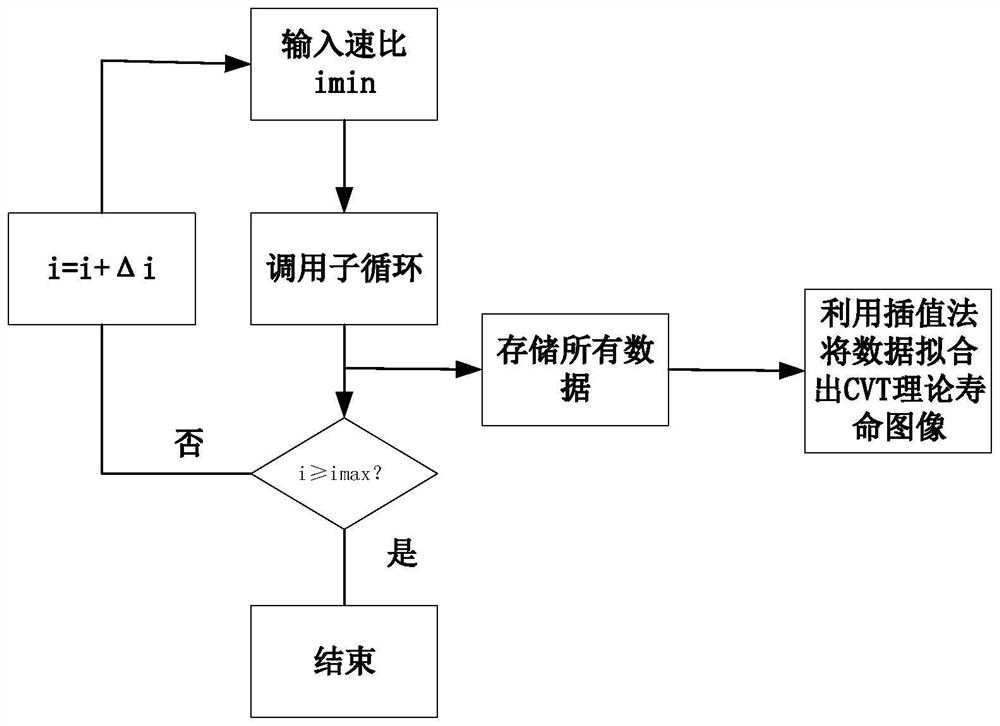

[0056] Step 3: Considering the two situations of speed, torque change and speed ratio change under a fixed speed ratio, use the same life calculation method as in the previous step and combine the data interpolation method to obtain the theoretical life image of the CVT belt ring;

[0057] Step 4: Consider the general working conditions, first use statistical methods to obtain the probability distribution of the general working condition speed ratio, input tor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com