Production device and preparation method of silage

A technology for silage and production equipment, which is applied in the preservation methods of animal feed raw materials, biochemical equipment and methods, and biological material sampling methods, etc., can solve the problems of low degree of automation, low production efficiency, and inconvenience.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

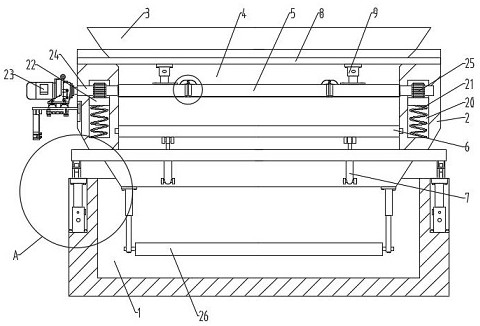

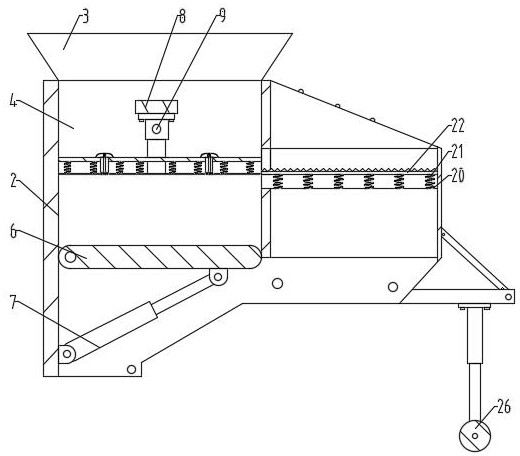

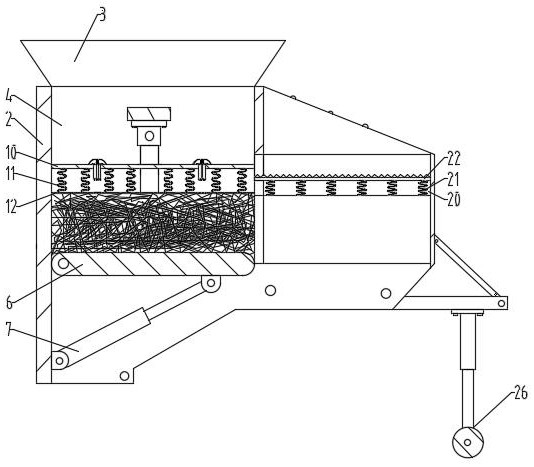

[0035] Example: as Figure 1-8 As shown, a production device for silage includes a pit 1 for storing silage and a rack 2 that can walk on the pit 1. The rack 2 passes through the walking devices installed on both sides of the pit 1. Drive to walk, the frame 2 is provided with a feed port 3 and a processing cavity 4 communicated with the feed port 3. The processing cavity 4 is provided with a laterally movable control processing cavity 4 at a position close to the middle thereof. The closed baffle plate 5 is provided with several exhaust components for exhausting the straw during the compaction process. The bottom of the processing chamber 4 is hinged with a blanking plate 6, and the machine The frame 2 is hinged with a hydraulic telescopic arm 7 for controlling the swing of the blanking plate 6; a power output mechanism for pressing the straw is fixedly installed in the processing chamber 4 at a position above the baffle plate 5; the power The output mechanism includes a conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com