Bedstead welding device and welding method thereof

A welding device and bed frame technology, applied in welding equipment, welding equipment, auxiliary equipment, etc., can solve the problems of slow manual single-point welding efficiency and poor welding quality consistency, and achieve large market promotion value and consistent appearance Good, good support and limit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1:, pic 1 and pic 2,100、200、 system 300 and 400,100,400100,400500。200210 and 220,210500,220500。 4 110120,120210 and 220500 system 300。 specific , pic 2 and pic 3,400410、420、430 and 440,410411、416 and 418,440 1 ,430440,411440。,416440,411 and 416,418 1 411 and 416,418 and 411 and 416。 ,416430417,417 and 430。, Embodiment 430,430416,410100,500 and 。 pic 3,500,411 no. 1 412, no. 1 412500 no. 1 413, no. 1 413500 no. 1 , no. 1 412418414,414500415,415500。 pic 3,420421、424 and 425,421100,421410410。424 1 421,425424,421500 no. 2 422, no. 2 422 and 411 no. 1 412,。 no. 2 422421 1 , no. 2 422500。 500 to 200,500 1 no. 2 422 no. 2 423,500 no. 1 412 and 414、 no. 2 422 and ,425 4 。 pic 4 and pic 6,210211、212 and 213,, Embodiment 211。211 and 212,211100,211100,211 and 50030-45,213,213T,500 or ,213 and 50030-45。213214,214 and system 300,213,211212215,212,212215。 pic 5 and pic 6,220221、222 and 223,, Embodiment 221。221222,221120,221120, and 50030-45,223,223T,500 or ,223 and 50030-45。223224,224 and system 300,223,221222225,222,222225。 pic 7,, Embodiment 500 pic 510,520,530,540,210510 and 520,220530 and 540。 Embodiment 2

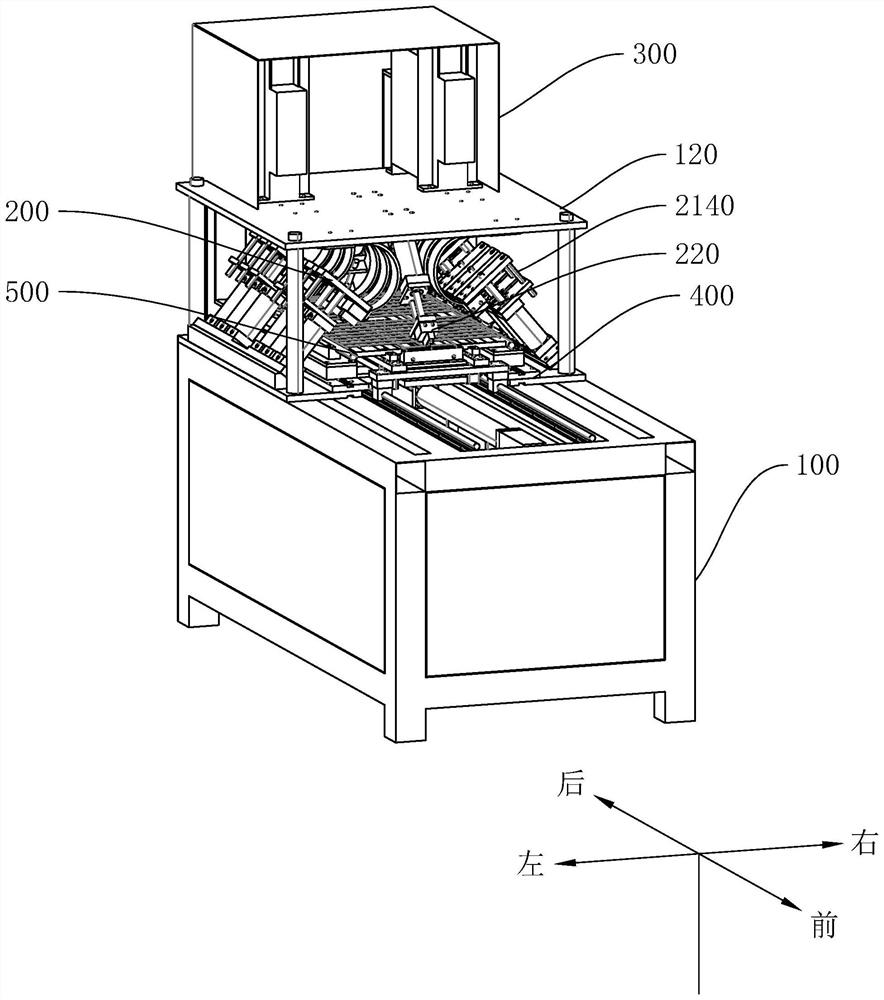

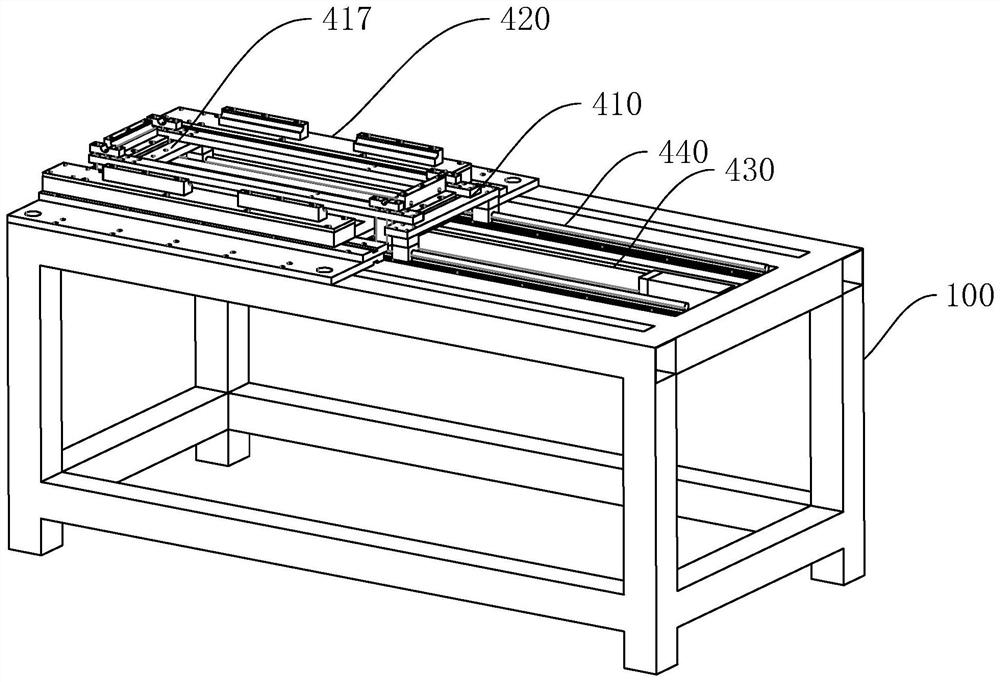

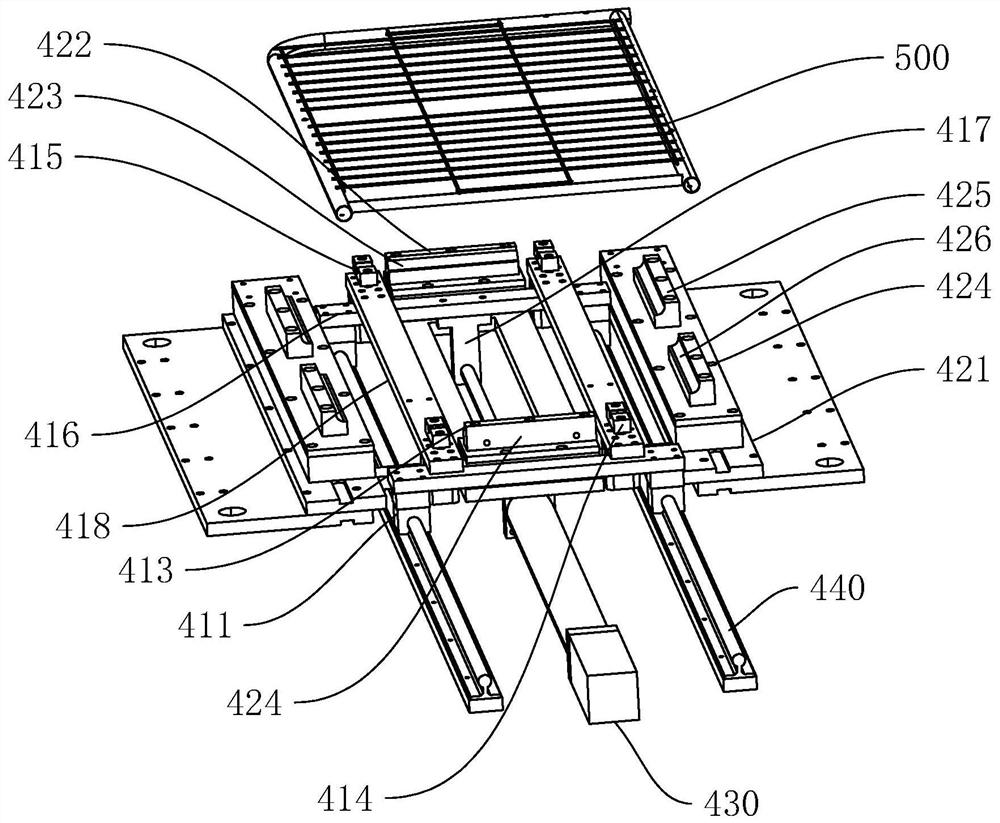

[0054] Example 1: Bed frame welding device, see figure 1 and figure 2 , including the frame 100 , the welding mechanism 200 , the control system 300 and the positioning mechanism 400 , the frame 100 is a rectangular structure, the positioning mechanism 400 is installed on the top of the frame 100 , and the bed frame assembly 500 is installed on the positioning mechanism 400 . The welding mechanism 200 includes a main welding frame 210 and an auxiliary welding frame 220 . The main welding frame 210 is symmetrically distributed along the left and right sides of the bed frame assembly 500 with a number of simultaneous welding points. The auxiliary welding frame 220 is along the front and rear of the bed frame assembly 500 . Symmetrical distribution in the middle of both sides. The outer periphery of the positioning structure is provided with a receiving plate 120 by setting four positioning columns 110 enclosed in a square shape. Welded fixed control system 300 . Specifically...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com