Sampling device for geological structure exploration

A sampling device and geological structure technology, applied in the direction of sampling devices, etc., can solve the problems of inconvenient use, easy to throw on the surrounding staff, and many on-site tools

Active Publication Date: 2022-06-21

CHENGDU UNIVERSITY OF TECHNOLOGY

View PDF15 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] However, when the existing sampling device is in use, the drill bit is used to drill the rock formation. When the drill bit is working, the drill bit needs to be cooled by spraying water, and the water flow at the drill hole is easily thrown to the surrounding area by the drill bit. The body of the staff, and when the existing sampling device is in use, the drilled core needs to be manually sampled by tapping the drill bit with a hammer, and there are many on-site tools for sampling, which is inconvenient to use

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

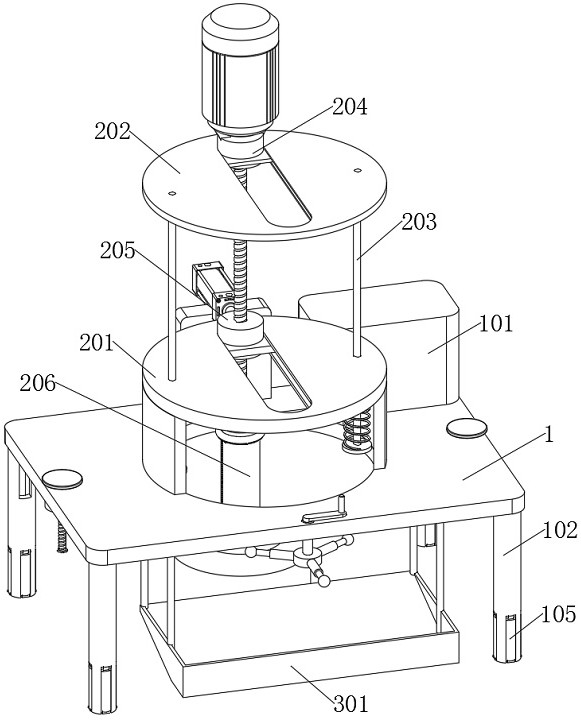

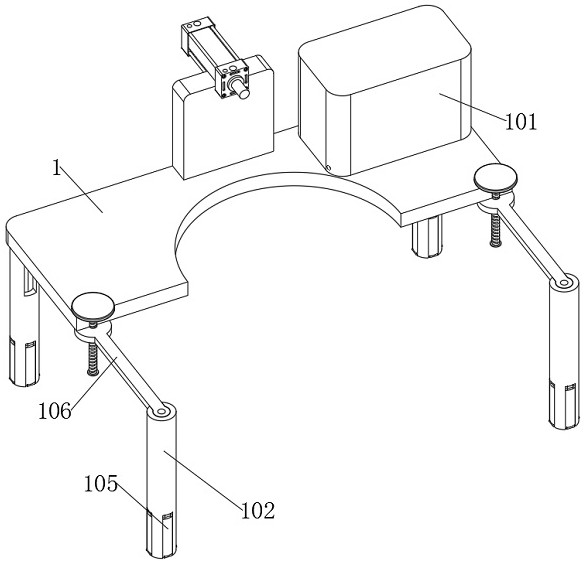

The invention provides a sampling device for geological structure survey, and relates to the technical field of geological survey sampling equipment.The sampling device comprises a main body, the main body is of a rectangular plate-shaped structure, an air cylinder is installed on the rear side of the top of the main body through a connecting plate, and an open groove is formed in the middle of the top of the main body and is of a circular structure; a rotating assembly is mounted at the top of the main body; the rotating assembly comprises a carrier plate, supporting plates are installed at the bottom of the carrier plate, the bottoms of the supporting plates are installed at the top of the main body, the supporting plates at the bottom of the carrier plate are located on the two sides of the open groove in the top of the main body, and a sliding groove is formed in the top of the carrier plate; and the material taking mechanism is mounted at the bottom of the main body. The protective cover moves along with the movement of the rotating part, so that the protective cover is placed on the ground to protect the periphery of the drilled hole, and the problems that when an existing sampling device is used, a drill bit needs to be cooled by spraying water flow, and the water flow is easily thrown to surrounding workers under the driving of the drill bit are solved.

Description

technical field [0001] The invention relates to the technical field of geological survey sampling equipment, in particular to a sampling device for geological structure survey. Background technique [0002] Geological structure survey refers to the exploration and detection of the shape left by the deformation or displacement of the rock layer or rock mass under the internal and external stress of the earth by various means. In the process of surveying, a sampling device is required to sample the rock layer . [0003] However, when the existing sampling device is in use, the drill bit is used to drill the rock formation. When the drill bit is working, the drill bit needs to be cooled by spraying water, and the water flow at the drill hole is easily thrown to the surrounding area by the drill bit. On the body of the staff, and when the existing sampling device is in use, the drilled core needs to be manually sampled by hammering the drill bit, and there are many on-site tool...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01N1/08

CPCG01N1/08

Inventor 张晨文华国马超王韶辉董翼昕孔祥晔王鑫

Owner CHENGDU UNIVERSITY OF TECHNOLOGY

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com