A hook anti-rotation positioning device

A positioning device and anti-rotation technology, applied in transportation and packaging, load hanging components, wind power generation, etc., can solve the problems of low adjustment efficiency, inconvenient adjustment, automatic adjustment of hooks, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

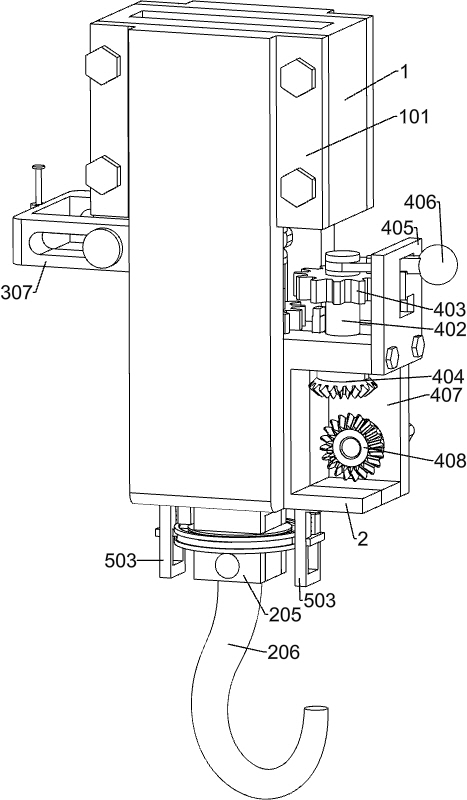

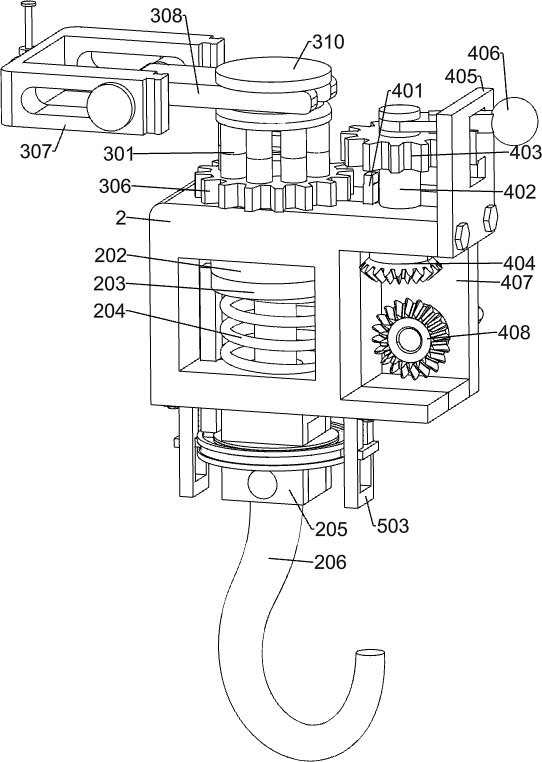

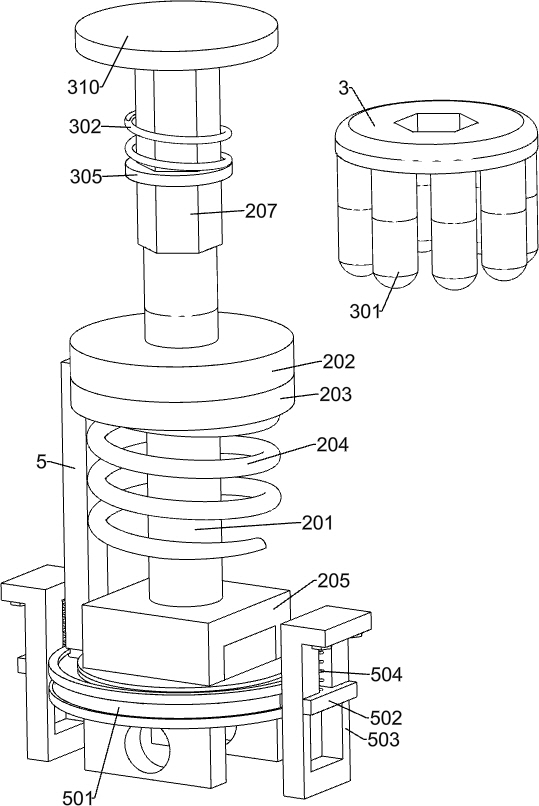

[0035] A hook anti-rotation positioning device, such as Figure 1-7As shown, it includes a connecting seat 1, a connecting plate 101, a bearing seat 2, a driving shaft 201, a first pressure plate 202, a second pressure plate 203, a return spring 204, a connecting block 205, a hook 206, a hexagonal prism 207, a limit For the position plate 303 and the limiting mechanism, the connecting base 1 is symmetrically fixed with two connecting plates 101, and the two connecting plates 101 are jointly fixed with the bearing seat 2, and the bearing seat 2 is rotatably connected with the driving shaft 201, the driving shaft A first pressure plate 202 is fixedly connected to the 201, a second pressure plate 203 is connected to the driving shaft 201, and a return spring 204 is sleeved on the driving shaft 201 for pushing the first pressure plate 202 and the second pressure plate 203 to reset upward. A connecting block 205 is fixed on the shaft 201, and a hook 206 for lifting goods is rotatab...

Embodiment 2

[0042] On the basis of Example 1, as figure 2 , Figure 4 and Figure 7 As shown in the figure, it also includes an adjustment mechanism that can drive the limit gear 306 to rotate when the goods are hoisted. The adjustment mechanism is installed on the bearing base 2, and the adjustment mechanism includes an adjustment spring 4, an adjustment rod 401, an adjustment shaft 402, and an adjustment gear. 403, the upper bevel gear 404, the adjustment guide plate 405, the adjustment handle 406, the adjustment connection plate 407, the lower bevel gear 408 and the adjustment handle 409, the limit plate 303 is slidingly connected with the bearing base 2 and connected with a plurality of adjustment springs 4, The limit plate 303 is fixedly connected with an adjustment post 401 slidably connected to the bearing base 2 , and the adjustment post 401 is used to drive the limit disc 303 to move downward. The bearing base 2 is slidably connected with an adjustment shaft 402 , and the adjus...

Embodiment 3

[0045] On the basis of Example 2, as figure 2 and image 3 As shown, it also includes a restricting mechanism that can restrict the up and down swing of the hook 206. The restricting mechanism is connected to the second pressure plate 203. The restricting mechanism includes a restricting post 5, a restricting ring 501 and a buffer guide assembly. The second pressure plate 203 is connected to the second platen 203. The first pressure plate 202 is rotatably connected, the second pressure plate 203 is fixedly connected with a restricting post 5, and the restricting post 5 is connected with a restricting ring 501 for restricting the swing of the hook 206, and the restricting ring 501 is sleeved on the connecting block 205, The limit ring 501 is connected with a buffer guide assembly for buffering and guiding it; when the driving shaft 201 moves downward, it will drive the first pressure plate 202 and the second pressure plate 203 to move downward, thereby driving the limit ring t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com