Manufacturing equipment of interphone integrated mainboard

A technology for manufacturing equipment and walkie-talkies, which is used in printed circuit manufacturing, printed circuits, electrical components, etc. to improve positioning and fixing efficiency, strengthen strength, and avoid cleaning.

Active Publication Date: 2022-06-10

深圳市华思物联科技有限公司

View PDF5 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] When the integrated motherboard on the walkie-talkie is manufactured, through holes need to be opened on the four corners of the motherboard to facilitate the later installation of the motherboard, while the integrated motherboard When the drilling device drills the main board, it needs to fix the main board to ensure the accuracy of the drilling. However, when the current drilling equipment fixes the main board, its fixing form is more complicated, and the operation is more time-consuming. It affects the working efficiency of drilling. In addition, when drilling, due to the lack of support at the drilling, cracks are prone to occur, resulting in the scrapping of the main board. Moreover, the waste generated after the drilling is completed falls on the drilling surface. It is not easy to clean up the equipment, and it takes a lot of manpower and time

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

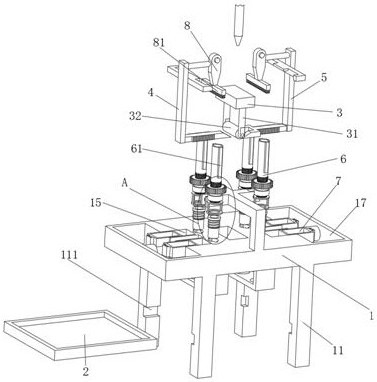

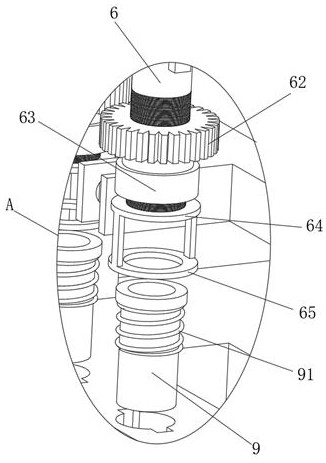

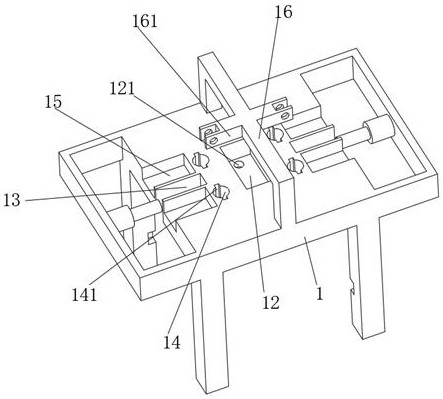

The invention relates to the technical field of interphone main boards, in particular to interphone integrated main board manufacturing equipment which comprises a drilling table, supporting legs are fixedly arranged at the lower end of the drilling table, inserting grooves are formed in the supporting legs, a rectangular hole is formed in the center of the upper end of the drilling table, two connecting holes are formed in the rectangular hole, and the two connecting holes are communicated with the drilling table. The connecting hole penetrates through the hole bottom of the rectangular hole, barrel holes are symmetrically formed in the two sides of the rectangular hole, two guide grooves are symmetrically formed in each barrel hole, mainboard supporting chip receiving devices are installed in the rectangular hole, the barrel holes and the supporting legs, moving grooves are symmetrically formed in the two ends of the drilling table, and the moving grooves are arranged in the rectangular hole. Mounting grooves are symmetrically formed in the positions, on the two sides of the moving groove, of the drilling table, the positioning and fixing efficiency of the main board is greatly improved very conveniently, and then the working efficiency of drilling is greatly improved.

Description

technical field [0001] The invention relates to the technical field of walkie-talkie motherboards, in particular to manufacturing equipment for walkie-talkie integrated motherboards. Background technique [0002] When the integrated main board on the walkie-talkie is being manufactured, through holes need to be opened on the four corners of the main board to facilitate the later installation of the main board, and the drilling device for the integrated main board needs to drill the main board when drilling holes. fixed to ensure the accuracy of the drilling, and the current drilling equipment fixes the motherboard when its fixing form is more complicated, and the operation is more time-consuming, which affects the drilling efficiency. In addition, when drilling Due to the lack of support at the drilled hole, cracks are prone to occur, resulting in the scrapping of the main board. Moreover, the waste generated after the drilling is completed falls on the drilling equipment an...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B26D7/02B26D7/18B26D7/00B26F1/16H05K3/00

CPCB26D7/025B26D7/18B26D7/00B26F1/16H05K3/0047B26D2007/0018

Inventor 邱中华邱根波

Owner 深圳市华思物联科技有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com