A high-precision instrument welding clamping mechanism

A welding clip, high-precision technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of affecting welding strength, inconvenient adjustment of butt coaxiality, and large coaxiality deviation, etc. To achieve the effect of improving the assembly process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

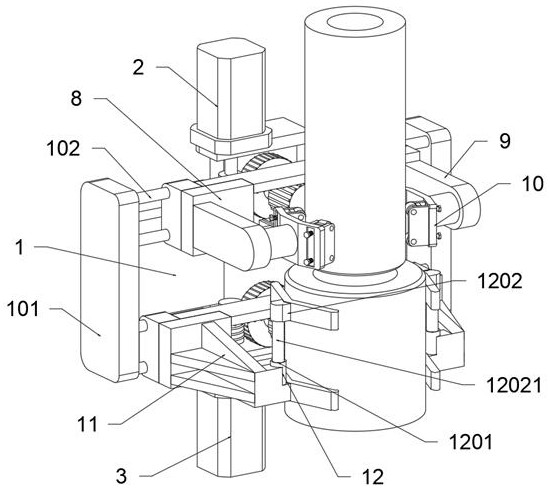

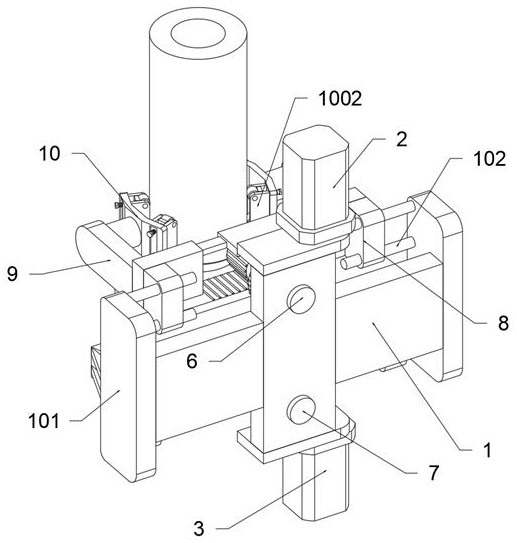

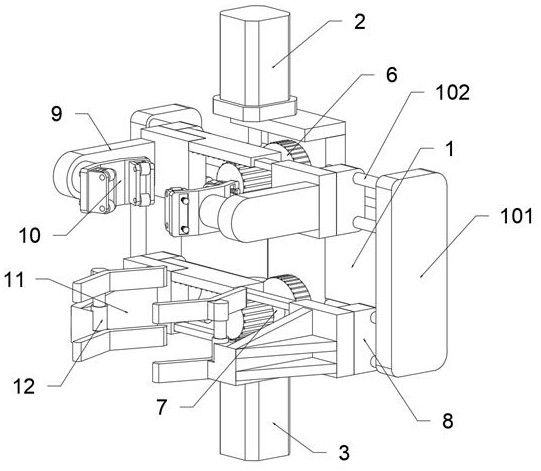

[0039] Example: please refer to Figure 1 to Figure 12 :

[0040] The present invention provides a high-precision instrument welding clamping mechanism, which includes a welding tool main frame body 1; A centering drive 3 is permanently connected, such as Figure 7 As shown, two sides of the main frame body 1 of the welding tool are respectively bent forward and provided with a side guide frame 101, and the inner surface of the side guide frame 101 is fixedly connected with four side guide columns 102 of cylindrical structure; the side guide columns 102 It is slidably connected with the balance guide hole 8011, and plays the role of balance support and guidance for the docking clamp 8; the output end of the clamping driver 2 is fixedly connected with the clamping worm 4; The end is fixedly connected with a centering worm 5; a clamping synchronization shaft 6, which is rotatably connected to the welding tool main frame 1 through a bearing; a centering synchronization shaft 7,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com