Fault monitoring method and device for automobile lamp

An automotive lamp and fault monitoring technology, which is applied in the direction of measuring devices, lamp testing, machine/structural component testing, etc. Reduced time consumption and less omissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

Embodiment 2

Embodiment 3

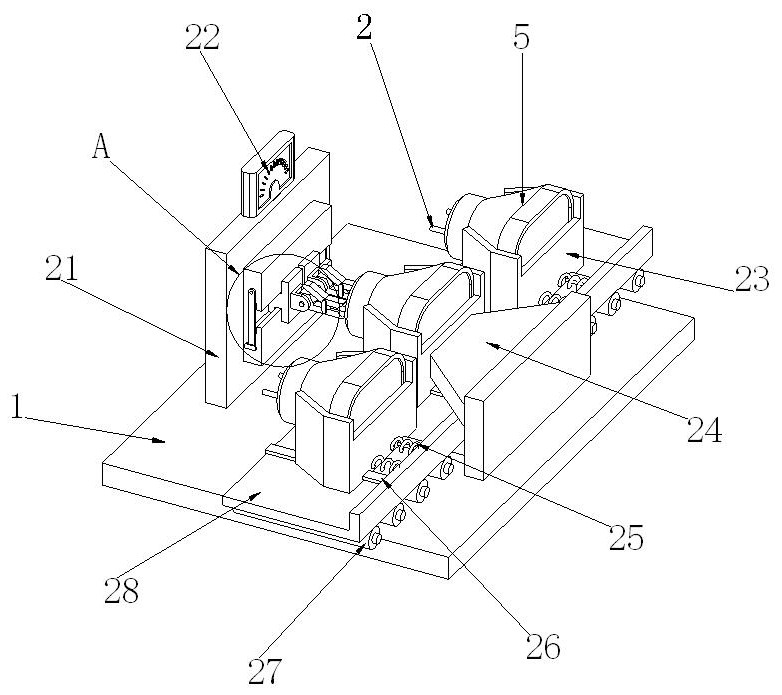

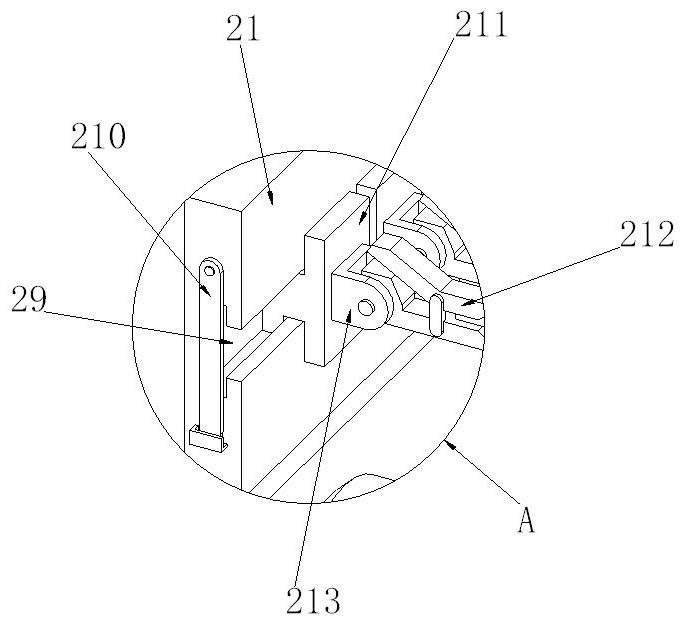

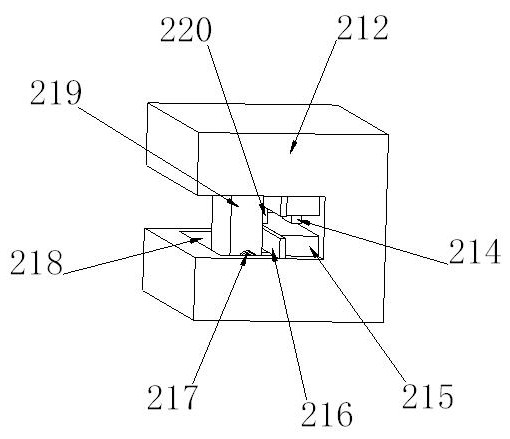

[0021] When the present invention is in use, according to the shape and size of the vehicle lamp body 5 to be detected, the positions of the two adjusting sliders 211 on the inner side of the transverse chute 29 are adjusted and fixed, and then the angle of the detection head 212 is detected by the rotating seat 213 Adjust and fix so that the position of the detection head 212 and the middle position of the vehicle lamp body 5 placed on the inside of the placing frame 23 are on the same horizontal plane, and the vehicle lamp body 5 to be detected is placed on the upper surface of the main conveyor belt 28. The upper surface is slidably connected. Place the inner side of the frame 23, so that the vehicle lamp body 5 is moved under the driving of the main conveyor belt 28. When the placement frame 23 moves to the position of the displacement guide plate 24, the placement frame 23 and the displacement guide plate 24 squeeze each other. Under the driving of the main conveyor belt 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com