A floating connection module and a smart bracelet acoustic performance test equipment

A floating connection and module technology, applied in measuring devices, using electromagnetic means, measuring ultrasonic/sonic/infrasonic waves, etc., can solve problems affecting the floating accuracy of floating mechanisms, affecting X-axis positioning accuracy, and sagging of floating connection mechanisms. Improve accuracy and test efficiency, improve test efficiency, and reduce the effect of debugging process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

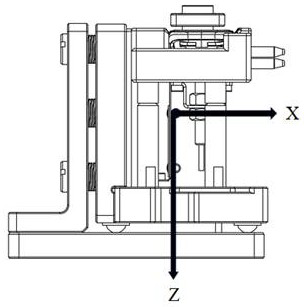

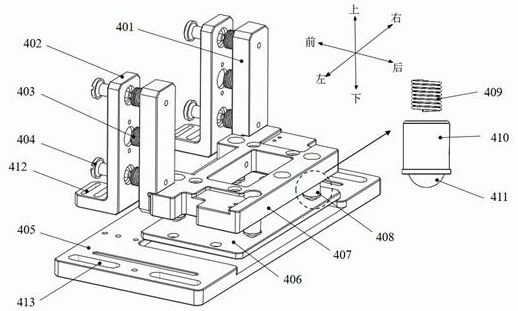

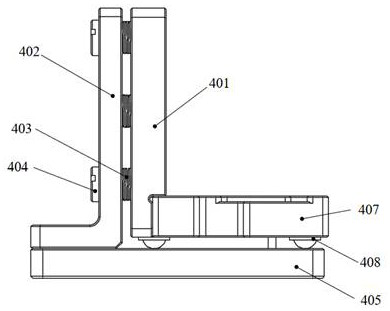

[0056] combine Figure 2-4 As shown, an embodiment of the present invention provides a floating connection module, including a first base plate 405, a first floating structure and a second floating structure;

[0057] The first floating structure includes a floating plate 407, two floating connection blocks 401 and two L-shaped support blocks 402; the horizontal bottom plate of the L-shaped support block 402 is fixedly connected to the first bottom plate 405, and the L-shaped support blocks The vertical plate of the block 402 is floatingly connected to the front end of the floating connecting block 401 through two equal-height screws 404 and three first compression springs 403 evenly distributed up and down; the bottom end of the rear side of the floating connecting block 401 is connected to the floating plate The front end of 407 is fixedly connected;

[0058] The second floating structure includes four universal positioning balls 408 arranged at the bottom end of the floati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com