Safety system for energy storage battery container

A safety system and energy storage battery technology, applied in the field of safety systems, can solve the problems that the coolant is difficult to directly act on the high temperature area, the battery is bulged and deformed, and it is difficult to isolate and extinguish the fire, so as to avoid secondary safety problems and reduce the dosage. , the effect of reducing the concentration of flammable gases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below with reference to the accompanying drawings and embodiments.

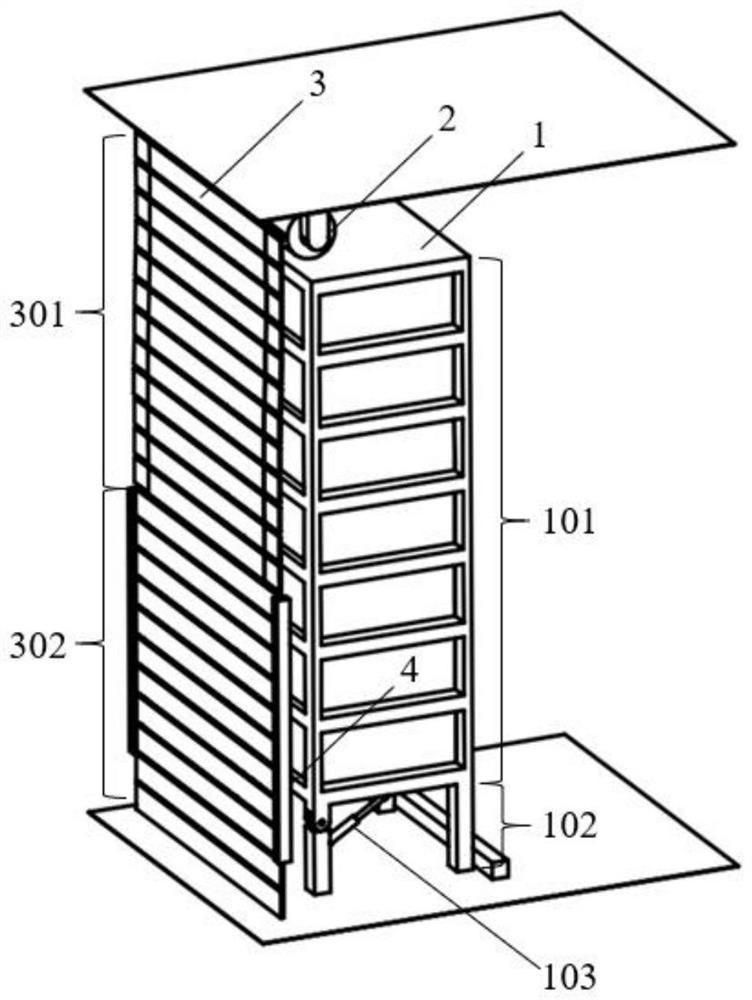

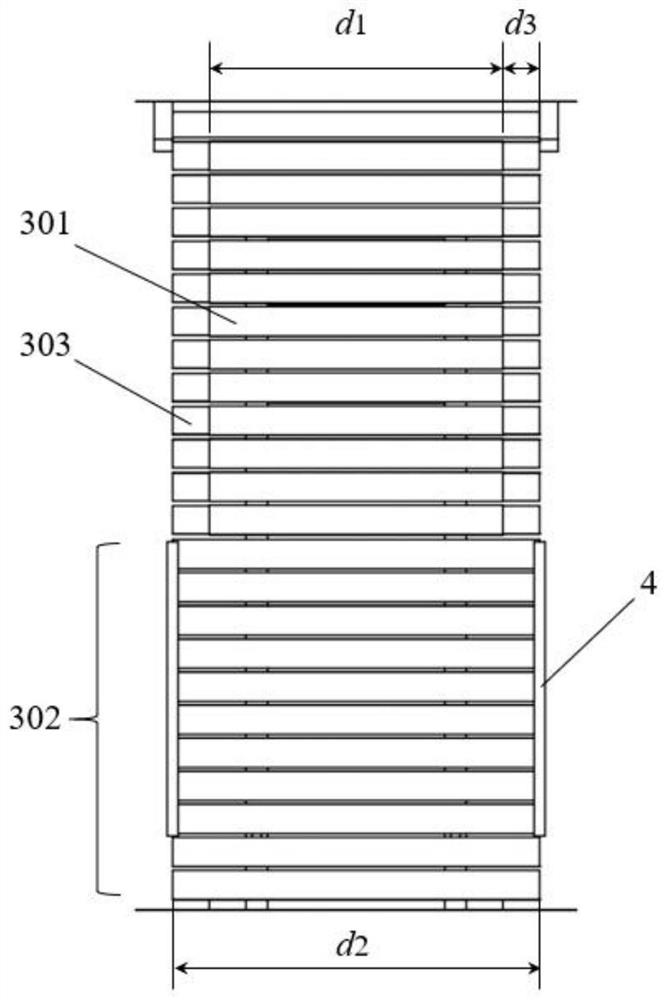

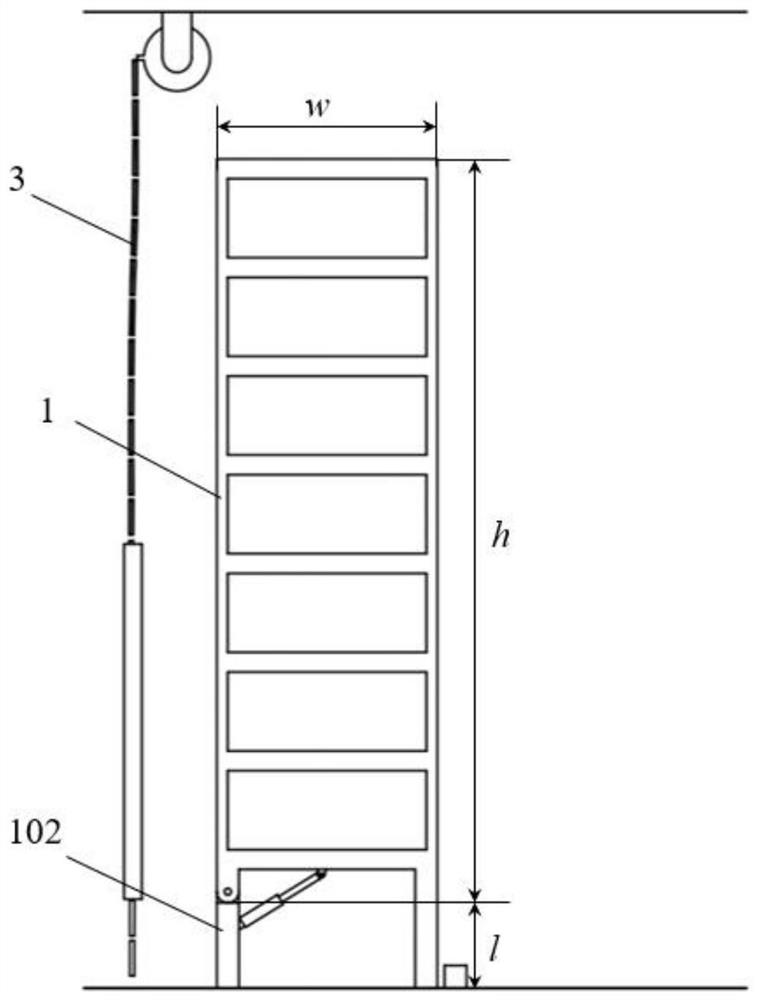

[0043] figure 1 It is a three-dimensional schematic diagram of a safety system for an energy storage battery container according to the present invention. A safety system for an energy storage battery container includes a control device, a battery rack 1 , a safety buffer door, and a sensor arranged in the battery box. The safety buffer door includes a winding motor (not shown in the figure), a reel 2 , a rolling shutter door panel 3 , a door frame (not shown in the figure) and a limiting portion 4 .

[0044] The winding motor is connected with the reel 2 to rotate the reel 2. The reel 2 is connected with the upper end of the rolling shutter door panel 3, and the rolling shutter door panel 3 includes an upper rigid strip 301 and a lower rigid strip 302. Normally, when the reel 2 rotates, the rolling shutter door panel 3 is wound on the reel 2 to open th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com