A hood type anti-sway building construction tower crane

A technology for tower cranes and building construction, which is applied in cranes, load hanging components, transportation and packaging, etc. It can solve the problems of lack of automatic anti-sway stability and balance function, inability to evenly guide and balance, inability to self-protect and balance, etc. , to achieve the effect of increasing friction, increasing contact area and reducing load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

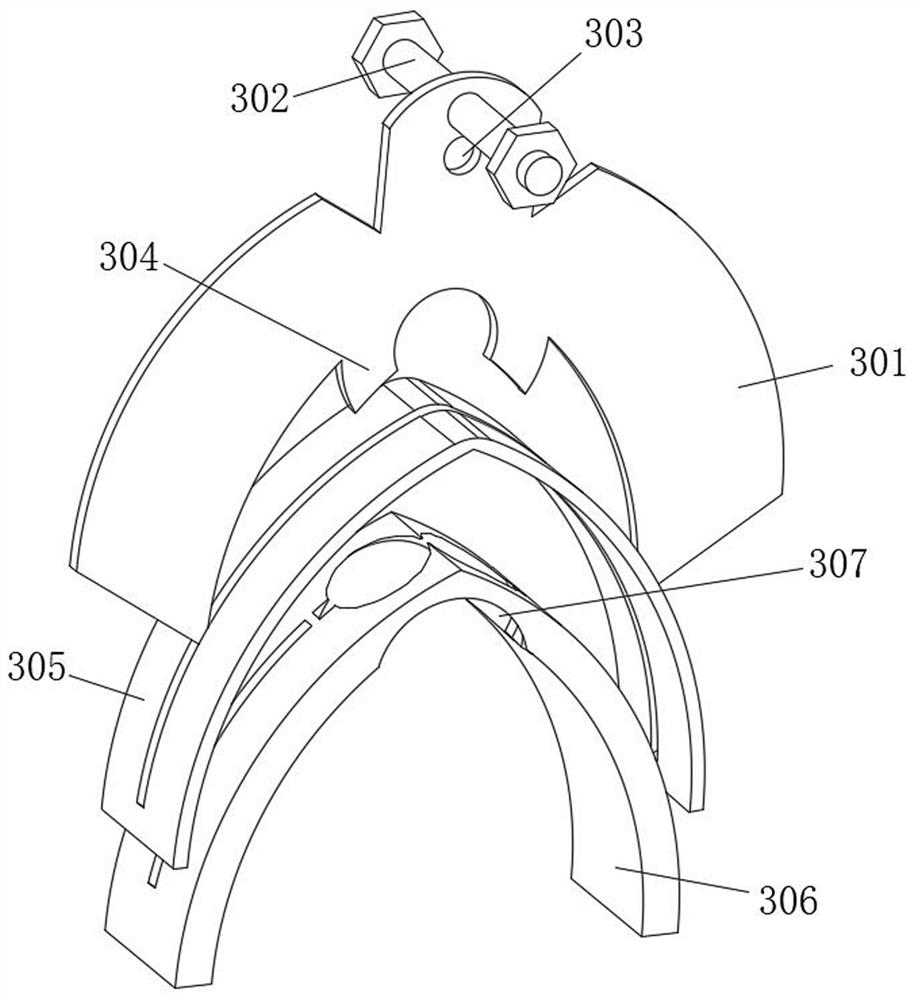

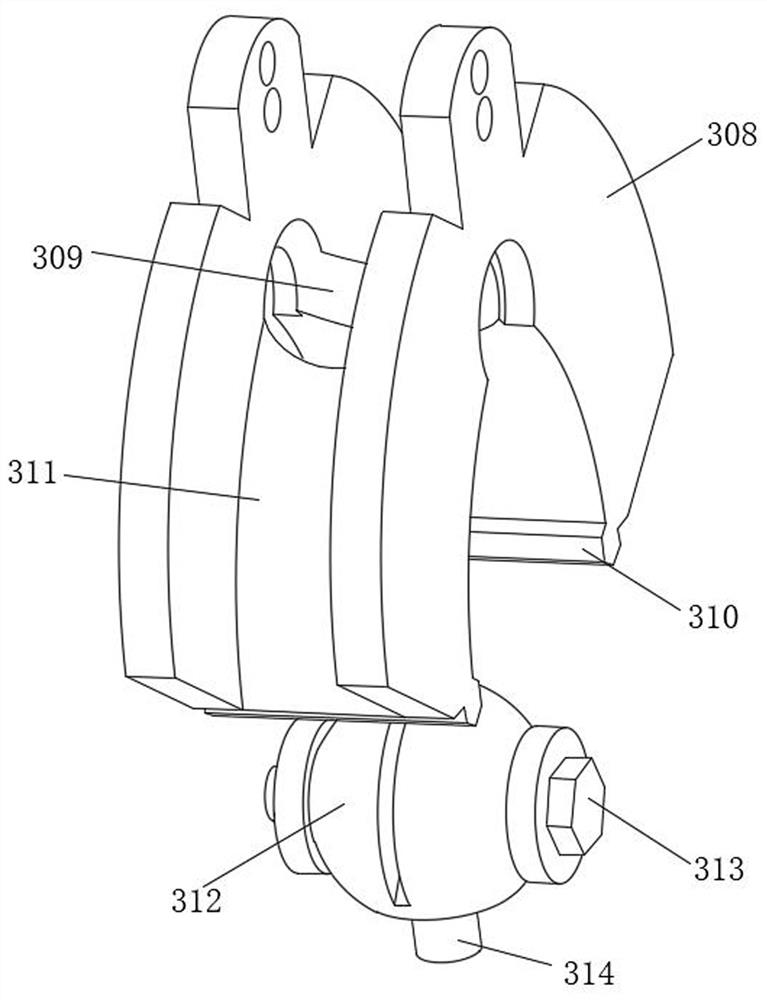

[0032] like Figure 1-Figure 7 As shown, the present invention provides a technical solution: comprising a tower arm structure 1, the upper end of the tower arm structure 1 is movably installed with a motor vehicle mechanism 2, the upper end of the motor vehicle mechanism 2 is installed with a front crane assembly 3, and the lower end surface of the front crane assembly 3 has two A lifting rod 4 is installed symmetrically on the side, and a torsion hanging assembly 5 is installed at the lower end of the lifting rod 4; A plastic pad 306 is installed at the lower end, an arch bridge 308 is installed at the lower end of the plastic pad 306, and a middle sphere 312 is installed in the middle of the lower end of the arch bridge 308; A through hole 303 is formed through the surface near the middle position of the upper side. The lower end surface of the pinch plate 301 is symmetrically connected with a lower pinch plate 304 on both sides. The inner side wall surface of the plastic p...

Embodiment 2

[0037] like Figure 5-Figure 7 As shown, the torsion hanger assembly 5 includes a bridging plate 501. Both sides of the inner side wall surface of the bridging plate 501 are fixedly connected with wall blocks 502. Both ends are fixedly connected with a sliding sleeve 507, and the front and rear ends of the sliding sleeve 507 are movably installed with lanyard hooks 509; the lower end of the bridge plate 501 is fixedly connected to the front and rear sides with a downward extension plate 504. The downward extension plate 504 There are limited rope holes 505 running through the surface of the rope, a plastic plate 508 is installed between the bridging plate 501 and the rope guide plate 506, the lower end of the rope guide plate 506 is installed with a split plate 510, and both sides of the upper end of the split plate 510 are fixedly connected There is an upper pinch plate 511, and a third screw 512 is installed in the middle position of the lower side of the splitter plate 510;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com