Anti-fragmentation clamping tool for new material production and processing and operation technology of anti-fragmentation clamping tool

An operating process and new material technology, applied in the field of anti-fragmentation clamping tools for the production and processing of new materials and their operation processes, can solve the problems of damage to new material products, fragmentation of new material products, etc., to ensure the effect of clamping and fixing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

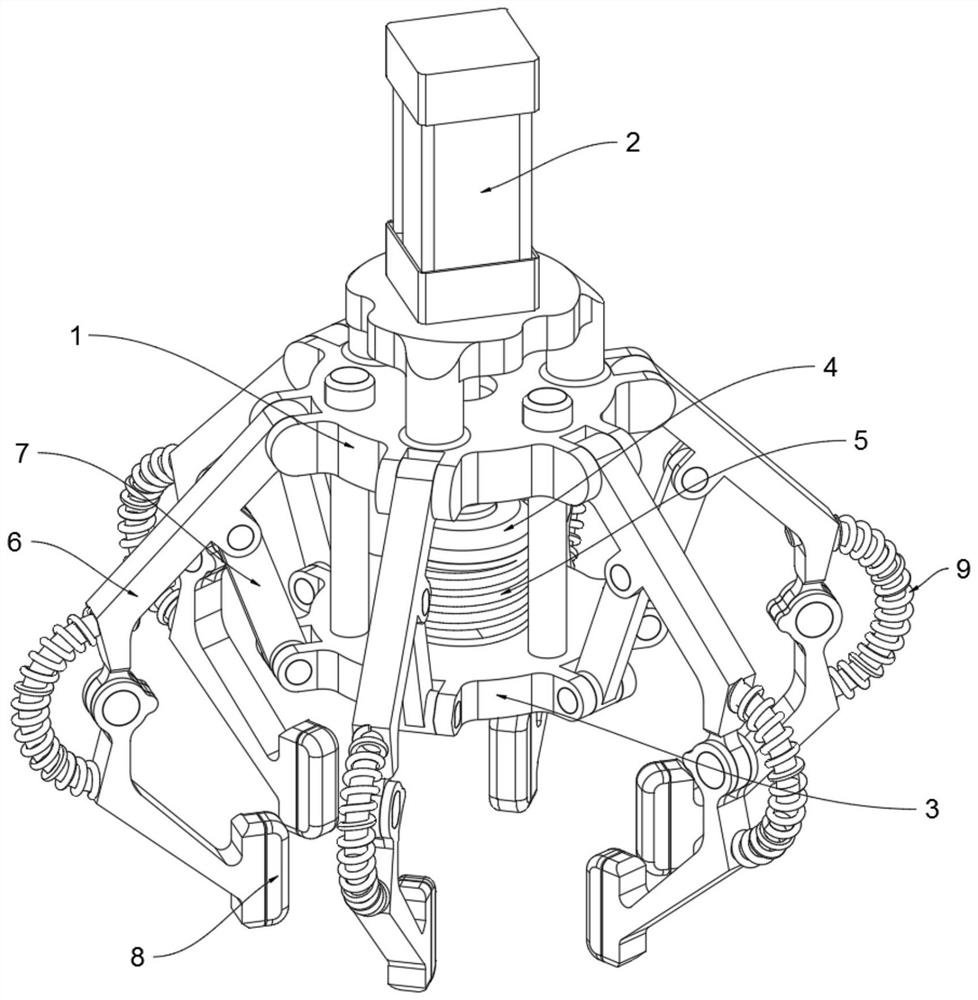

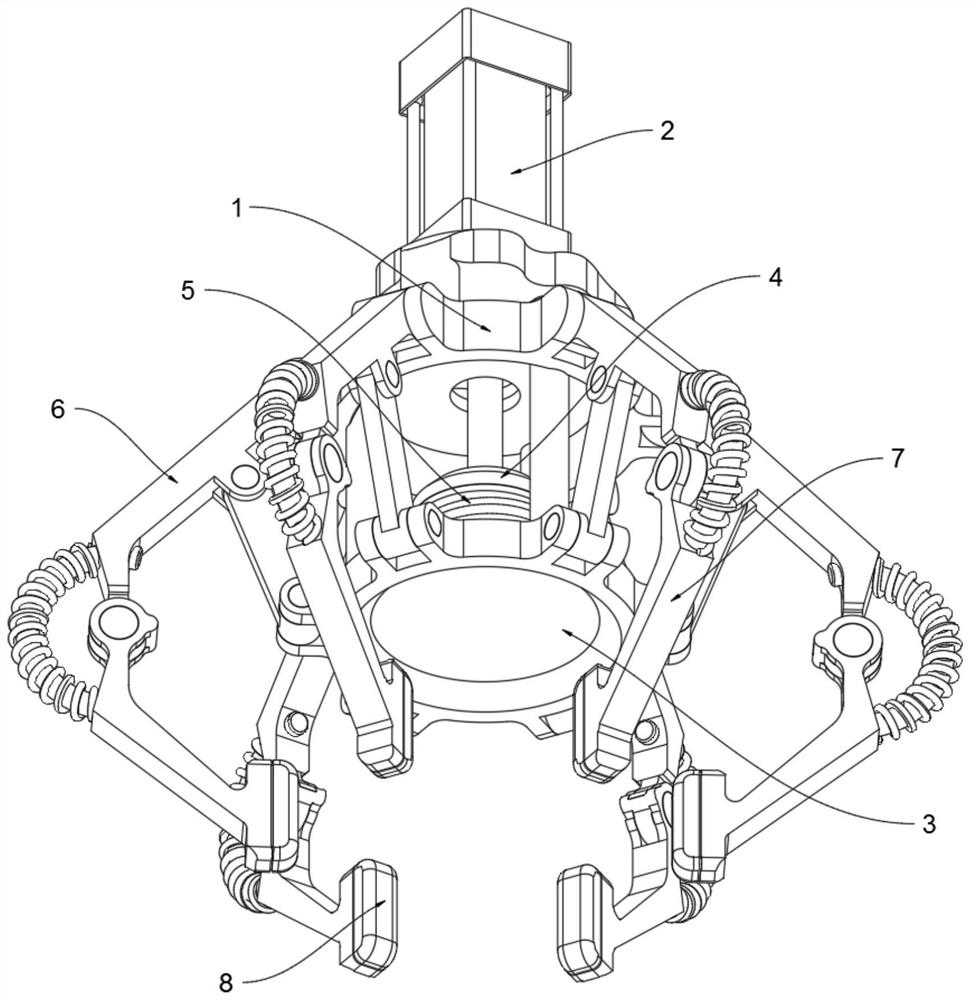

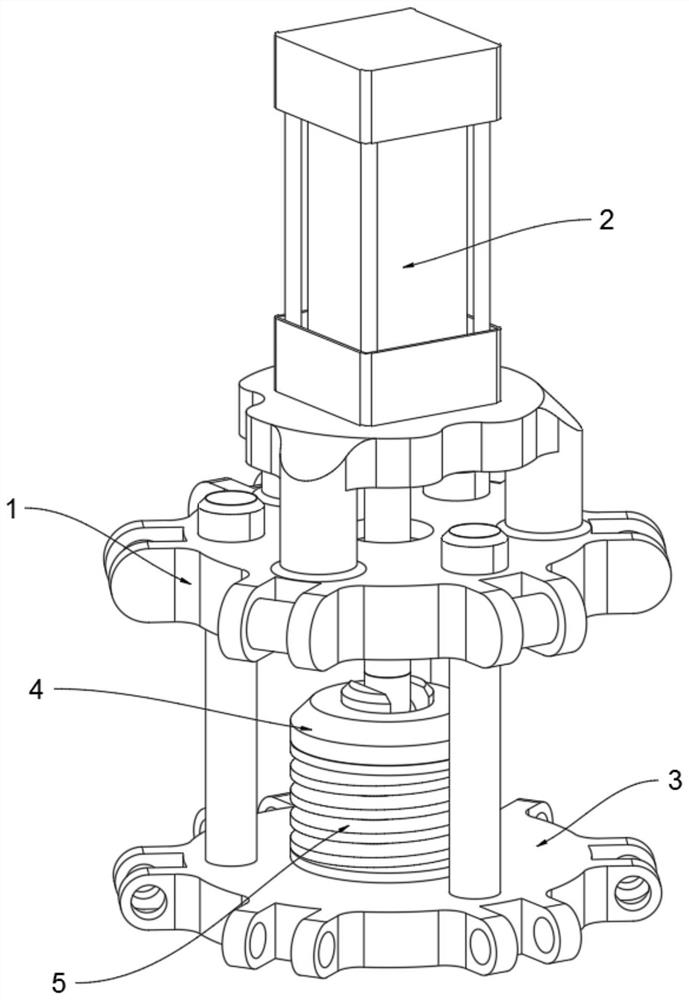

[0046] Please refer to Figure 1 to Figure 8 :

[0047] The present invention proposes an anti-fragmentation clamping tool for new material production and processing and its operation process, including: a top base 1, a movable base 3, a driving part 4, jaws 6 and a driving connecting rod 7;

[0048] The top seat 1 has a double-layer structure, and the interior of the top seat 1 is surrounded by three guide slide holes 101, and the pneumatic part 2 is installed on the top side of the top seat 1 in an inverted shape; the movable base 3 is located at the bottom of the top seat 1, and the movable The top side of the base 3 is surrounded by three guide sliders 301, and the guide sliders 301 are slidably connected in the guide slide holes 101; the driver 4 is connected to the top of the movable base 3, and the piston rod at the bottom of the pneumatic part 2 is connected to the driver. 4 are connected; the top of the jaw 6 is connected with the top seat 1, and the jaw 6 is connect...

Embodiment 2

[0054] Gripper jaw 6 is made of two parts, upper clamping rod 601 and lower clamping rod 602, and the top of upper clamping rod 601 is rotatably connected with top base 1, the bottom of upper clamping rod 601 is rotatably connected with the top of lower clamping rod 602, and the upper clamping rod 601 is connected with the top of lower clamping rod 602. The rotation angle of the lower clamping rod 602 is 0-120 degrees. The upper clamping rod 601 is provided with a curved sliding hole 6011 inside, and the outer side of the lower clamping rod 602 is provided with a curved sliding rod 6021, and the curved sliding rod 6021 is slidably connected to the curved sliding hole 6011. Inside, an auxiliary spring 9 is set on the outer side of the arc-shaped sliding bar 6021, and the upper and lower ends of the auxiliary spring 9 are attached to the upper clamping rod 601 and the lower clamping rod 602 respectively;

[0055] With the above technical solution, according to the different specifi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com