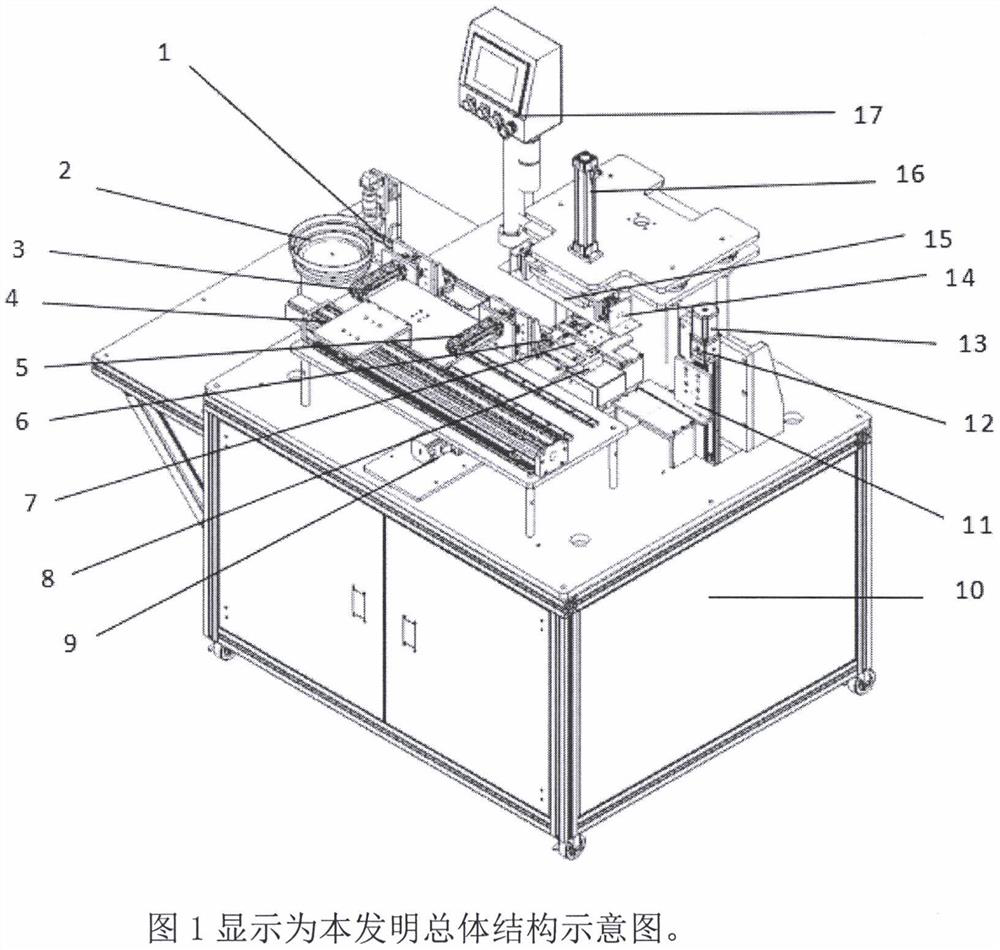

Full-automatic bipolar magnetizing equipment

A magnetizing equipment, fully automatic technology, applied in the direction of magnetic objects, circuits, electrical components, etc., can solve the problems of easy deformation of the magnetizing plate, inaccurate positioning of the equipment, and easy deformation of the positioning plate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

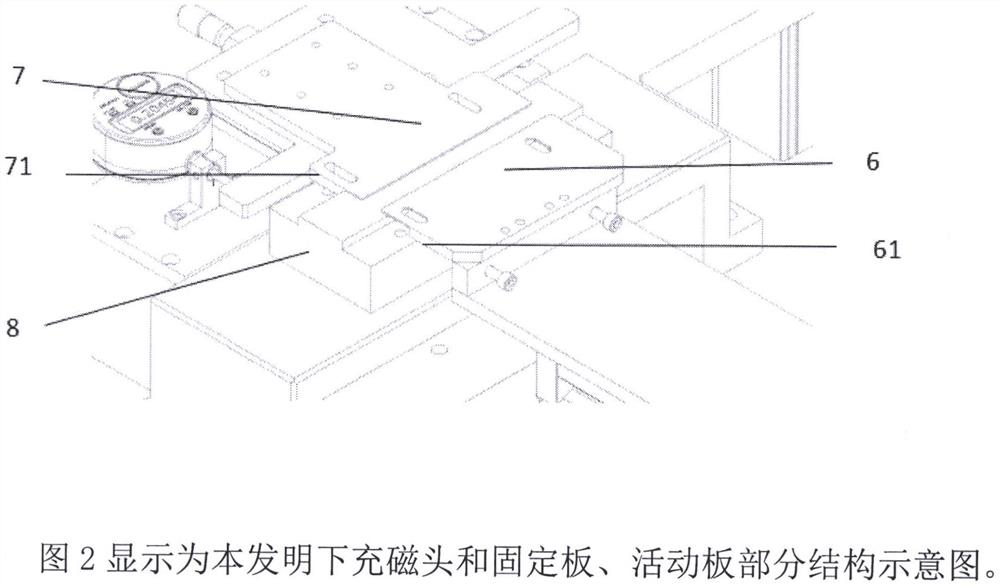

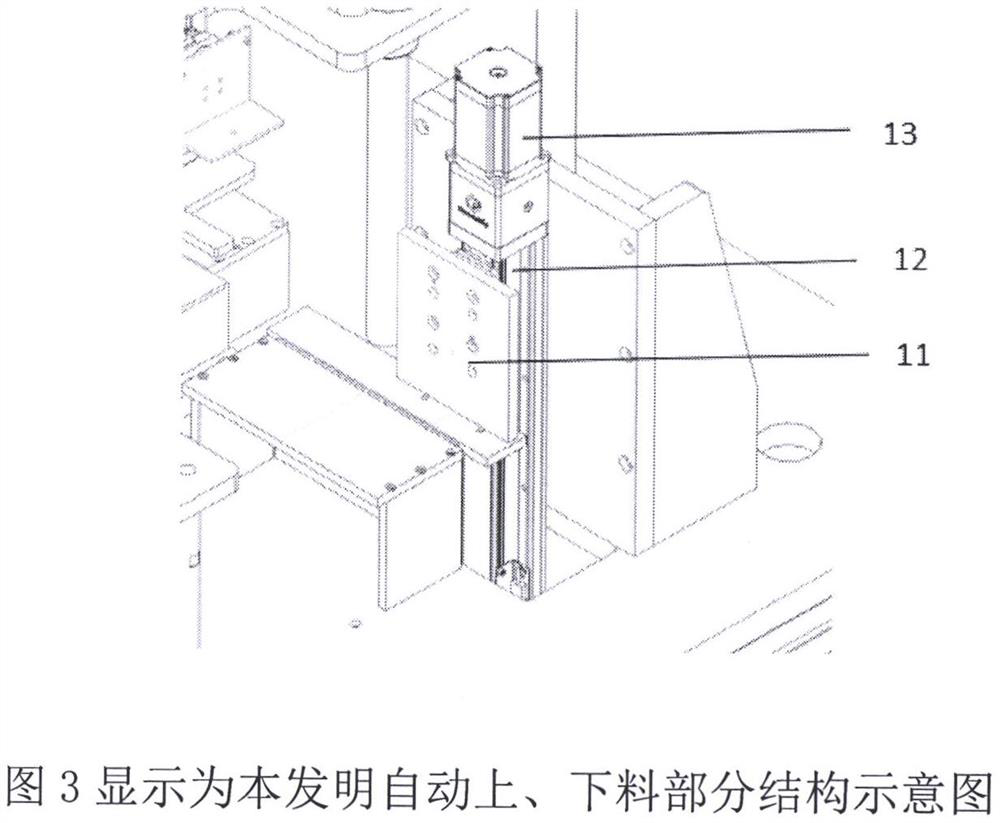

[0021] The size of the magnet for bipolar magnetization is 4.52*2.06*0.97 mm, 0.97 mm is the magnetization direction, the effective length of the magnetization head is 165 mm, 30 pieces are magnetized each time, the equipment is fully automatic, and the output is about 6000 pieces per hour.

[0022] The full-automatic bipolar magnetization equipment is used for magnetization, and compared with the manual magnetization method. Operators: one operator is arranged for each of the two magnet magnetization methods.

[0023] The average magnetization of traditional domestic artificial magnets is about 800 pieces per hour. The automatic magnet installation equipment of the present invention completes the magnetization of about 6000 pieces per hour on average, and the magnetization efficiency is increased by 5.5 times. The NS pole error ratios of the two magnetization methods are all within the range of 5MT, and the magnetization is qualified.

[0024] The average continuous working t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com