Equipment and method for preparing hexamethylene diisocyanate through pyrolysis in mixed solvent

A technology of hexamethylene diisocyanate and mixed solvents, which is applied in the field of pyrolysis to prepare hexamethylene diisocyanate, can solve the problems of high energy consumption and large investment, and achieve the effects of avoiding energy waste, solving potential safety hazards, and improving yield and purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

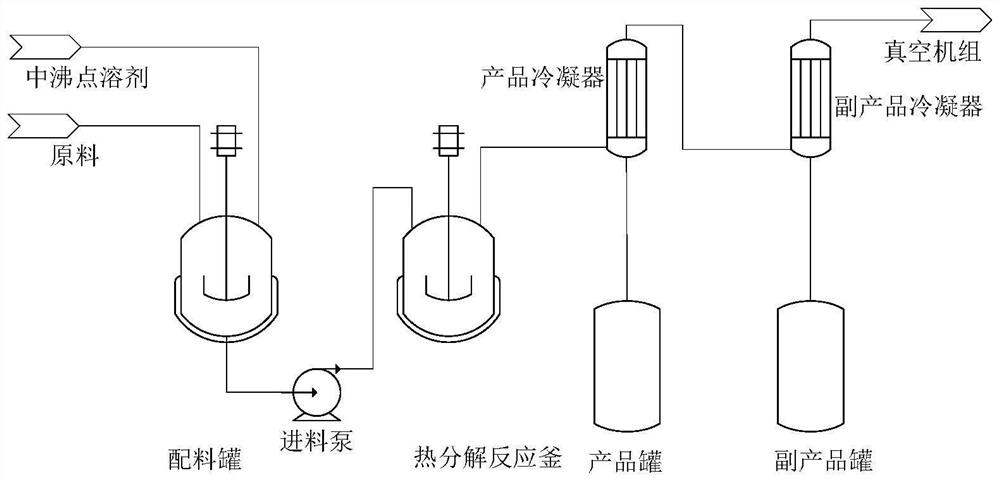

[0038] In this embodiment, the method for preparing hexamethylene diisocyanate by pyrolysis in a mixed solvent comprises the following steps:

[0039]Add the raw material 1,6-hexamethylene dicarbamate methyl ester and the medium-boiling point solvent biphenyl into the batching tank 1 according to the mass ratio of 1 / 1, and the total amount of 1,6-hexamethylene dicarbamate methyl ester and the medium-boiling point solvent biphenyl is 2000g , mix 1,6-hexamethylene dicarbamate and biphenyl in batching tank 1 and preheat to 80°C to form solution A;

[0040] The thermal decomposition reactor 2 is pre-filled with 50g catalyst nano-zinc oxide and 1000g high boiling point solvent dioctyl sebacate, solution A is transported to the thermal decomposition reactor 2000mL by the feed pump at a flow rate of 10mL / min;

[0041] The thermal decomposition reactor 2, the product condenser 4, the by-product condenser 5, the product tank 6 and the by-product tank 7 are all pumped to a negative pres...

Embodiment 2

[0044] In this embodiment, the method for preparing hexamethylene diisocyanate by pyrolysis in a mixed solvent comprises the following steps:

[0045] Add the raw material 1,6-hexamethylene dicarbamate methyl ester and the medium-boiling point solvent biphenyl into the batching tank 1 according to the mass ratio of 1 / 1, and the total amount of 1,6-hexamethylene dicarbamate methyl ester and the medium-boiling point solvent biphenyl is 2000g , mix 1,6-hexamethylene dicarbamate and biphenyl in batching tank 1 and preheat to 80°C to form solution A;

[0046] The thermal decomposition reactor 2 is pre-filled with 100g catalyst nano-Zn and 1000g high boiling point solvent octyl phthalate, and solution A is transported to the thermal decomposition reactor 2000mL by the feed pump at a flow rate of 20mL / min;

[0047] The thermal decomposition reactor 2, the product condenser 4, the by-product condenser 5, the product tank 6 and the by-product tank 7 are all pumped to a negative pressur...

Embodiment 3

[0050] In this embodiment, the method for preparing hexamethylene diisocyanate by pyrolysis in a mixed solvent comprises the following steps:

[0051] Add the raw material 1,6-hexamethylene dicarbamate methyl ester and the medium-boiling point solvent biphenyl into the batching tank 1 according to the mass ratio of 1 / 1, and the total amount of 1,6-hexamethylene dicarbamate methyl ester and the medium-boiling point solvent biphenyl is 2000g , mix 1,6-hexamethylene dicarbamate and biphenyl in batching tank 1 and preheat to 80°C to form solution A;

[0052] Thermal decomposition reactor 2 is pre-filled with 500g catalyst Zn-ZSM and 1000g high boiling point solvent paraffin, and solution A is transported to thermal decomposition reactor 2000mL by feed pump at a flow rate of 50mL / min;

[0053] The thermal decomposition reactor 2, the product condenser 4, the by-product condenser 5, the product tank 6 and the by-product tank 7 are all evacuated to a micro-negative pressure state wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com