Multi-layer sliding rail composite motion mechanism and application thereof

A composite motion, slide rail technology, applied in conveyors, transportation and packaging, electrical components, etc., can solve the problem of transporting the product to be tested to the center of the soundproof box, transporting the product to be tested in the soundproof box, increasing the volume of the soundproof box, etc. problem, to improve the effect of acoustic function test, increase the effective movement stroke, and run sensitively.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

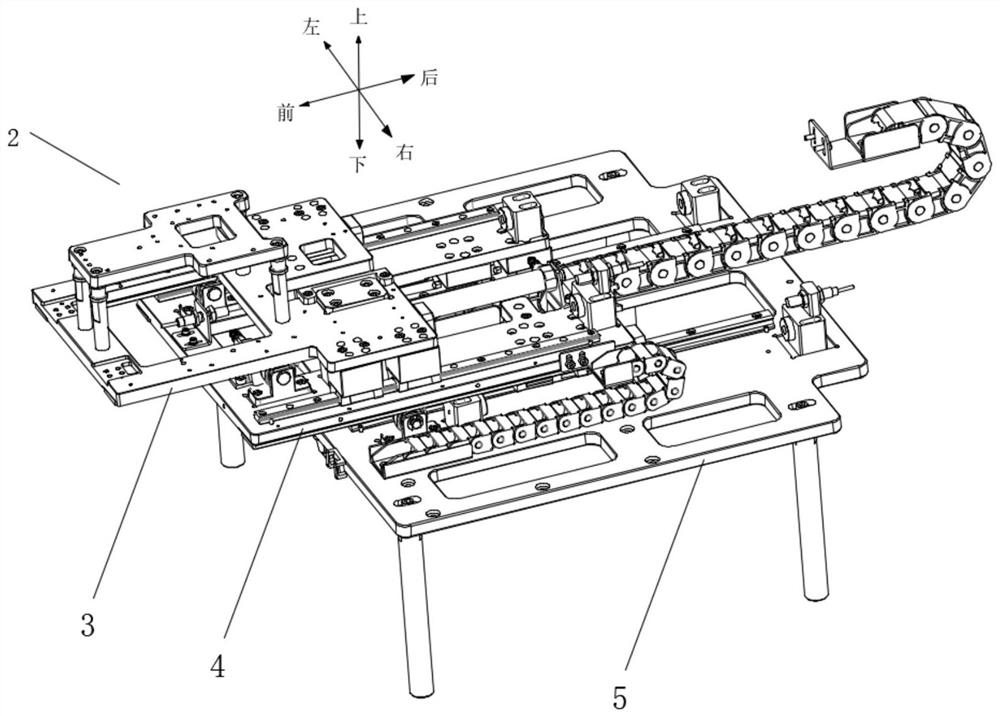

[0034] Such as figure 1 As shown, the present invention provides a multi-layer slide rail compound motion mechanism, the multi-layer slide rail motion mechanism includes a motion module 2, and the motion module 2 includes a carrier module 3, an upper slide rail module 4 and the lower slide module 5; the carrier module 3 is used to place the product to be tested, the carrier module 3 is slidably connected to the upper slide module 4, and the upper slide module 4 Slidingly connected to the lower slide rail module 5.

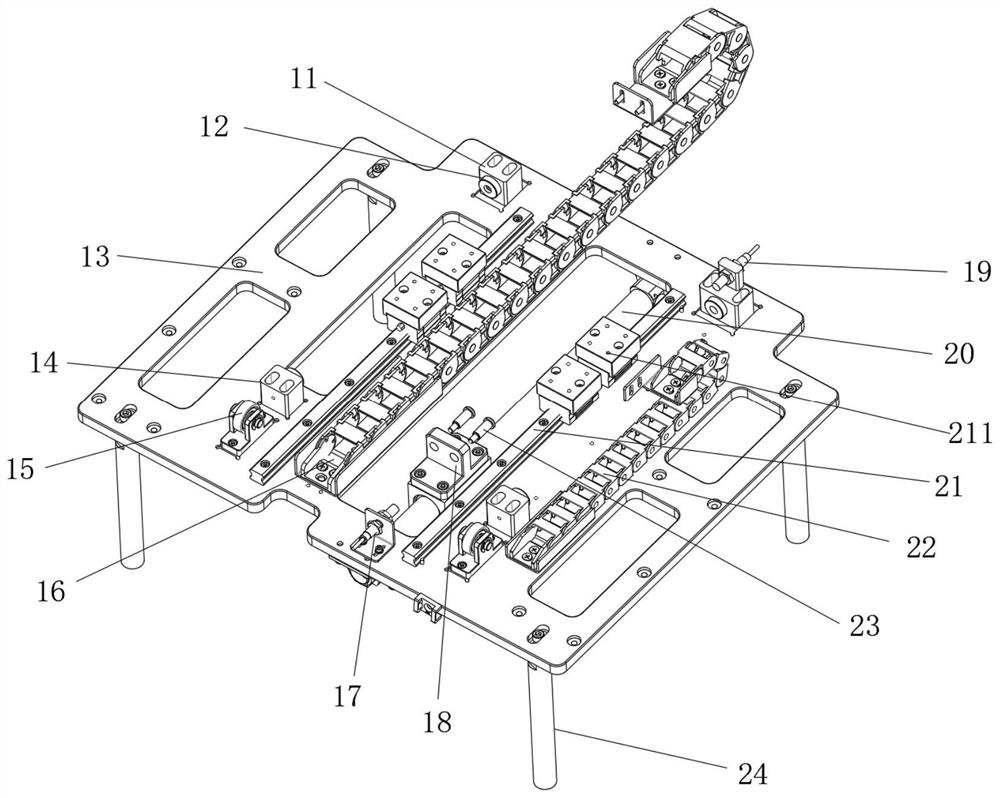

[0035] Such as figure 2 As shown, the lower slide module 5 includes a lower base plate 13 and two lower linear slide rails 21 fixed parallel and symmetrically on the lower base plate 13, and the two lower linear slide rails 21 are fixedly connected to the upper layer through the lower slide block 211. The slide rail module 4; the lower bottom plate 13 is provided with a lower front sensor 17 and a lower rear sensor 19 respectively near the front and rear ends, w...

Embodiment 2

[0044] Such as Figure 6 As shown, the present invention provides a soundproof box 1, the inner cavity of the soundproof box 1 is fixedly installed with the movement module 2 in the first embodiment, and the movement module 2 passes through the lower end of the lower bottom plate 13 of the lower slide rail module 5 The four bottom plate support columns 24 provided are fixedly installed on the inner cavity bottom plate of the soundproof box 1 . Wherein, the soundproof box 1 provides a low-noise environment for acoustic testing and shields noise interference from the external environment; the moving module 2 is used to transport test products into and out of the soundproof box for testing.

[0045] Test process: First, manually place the product to be tested on the carrier base plate 46 of the carrier plate module 3, and accurately locate it by the profiling positioning block set on the carrier base plate 46; then press the start button on the soundproof box 1 button, the upper...

Embodiment 3

[0048] In addition, the present invention also provides a machine loading and unloading transportation device, which also uses any of the above-mentioned multi-layer slide rail compound motion mechanisms to realize product transportation on the production line and complete the product loading and unloading process.

[0049] It needs to be added that the above embodiment is a double-layer slide rail compound motion mechanism. In practical applications, more than two layers of multi-layer slide rail compound motion mechanisms can be adaptively set according to the structure of this embodiment, and its structural principle is similar to , and will not repeat them here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com