Counterweight structure of construction machinery

A technology of construction machinery and main counterweight, which is applied to earth movers/shovels, construction, vehicle parts, etc., which can solve problems such as difficult adjustment of counterweight weight, safety accidents, and counterweight jamming, and achieve easy disassembly and assembly , smooth maintenance, and the effect of maintaining weight balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] Preferred embodiments of the counterweight structure of construction machinery of the present invention will be described in detail below with reference to the accompanying drawings.

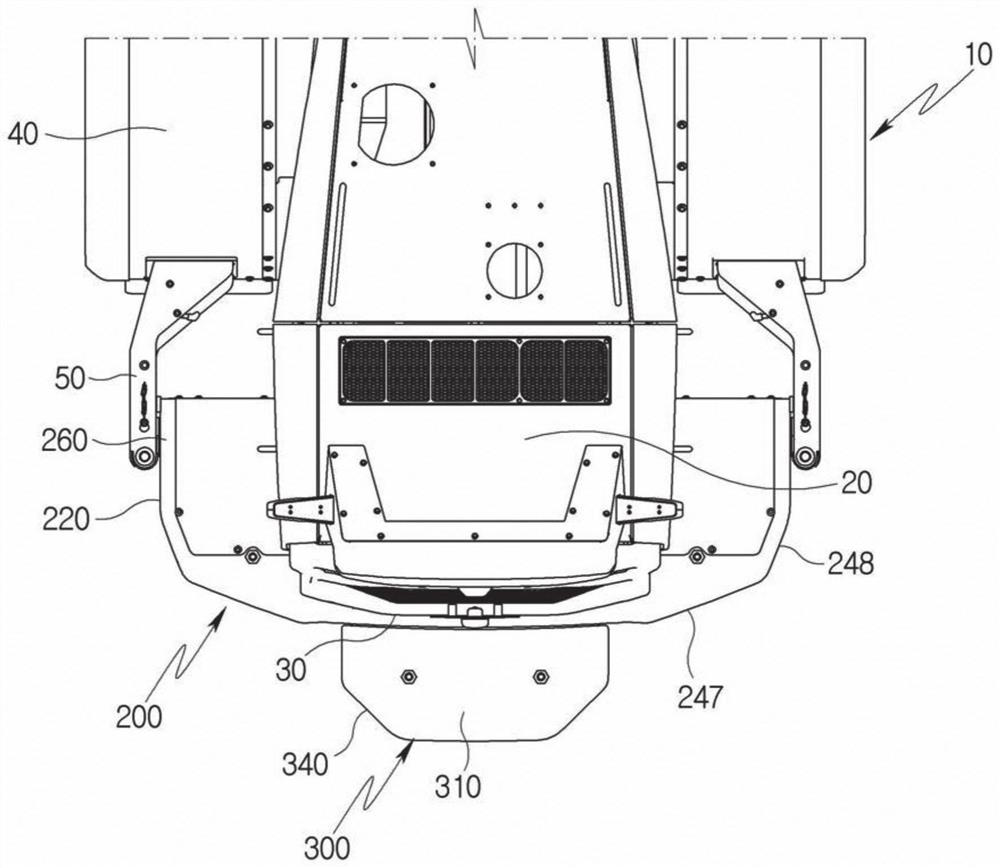

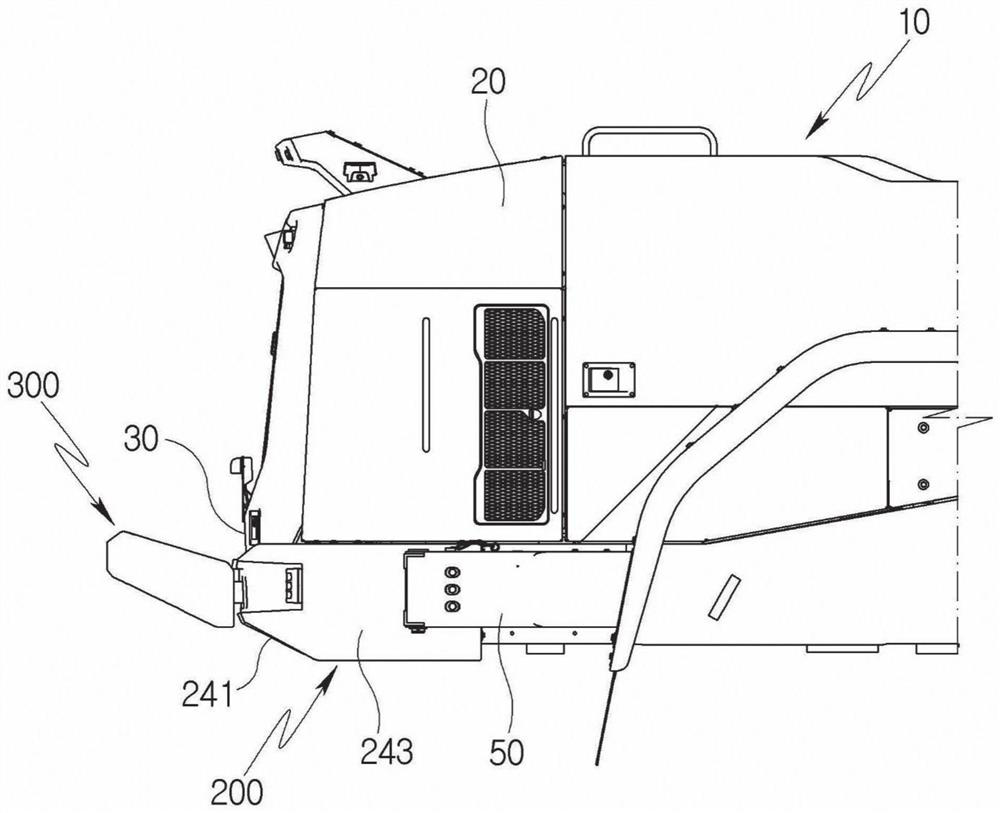

[0050] The counterweight structure 100 of the construction machine of the present invention may be configured to include a main counterweight 200 and a sub counterweight 300 .

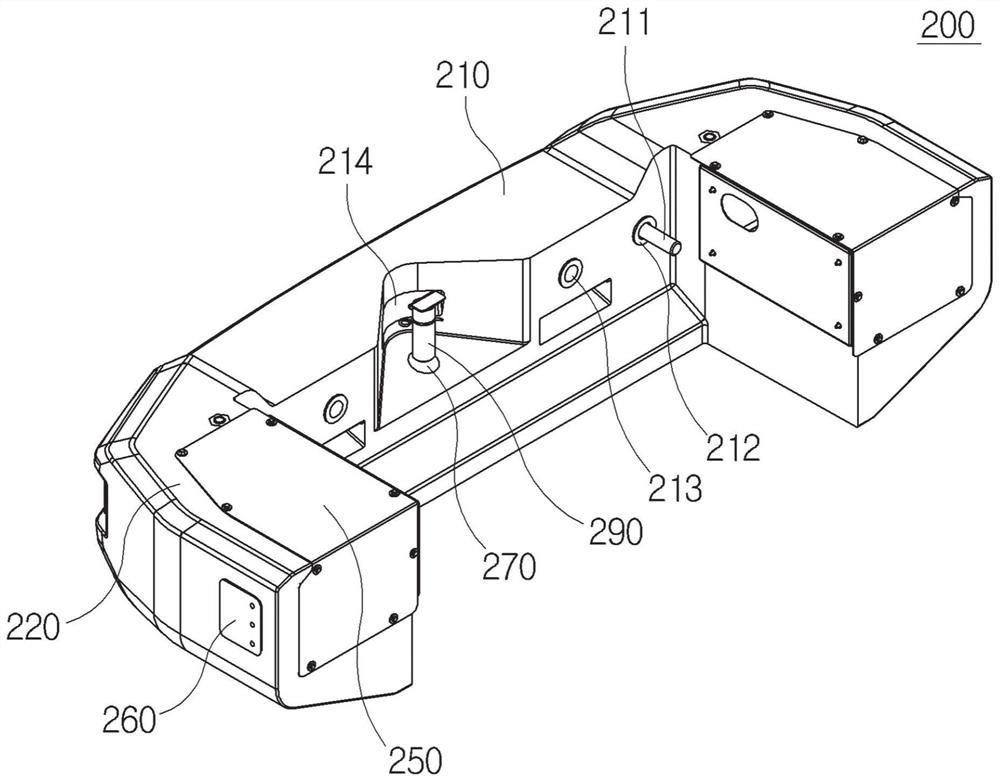

[0051] refer to Figure 2a to Figure 2h , the main counterweight 200 may be configured to include a central portion 210 , a side portion 220 , a battery space portion 250 , a pull-type fender mounting portion 260 and a traction pin mounting portion 270 .

[0052] The central part 210 can be made of metal material, and can be the front surface part 30 (refer to Figure 1a to Figure 1b)part. Such a central portion 210 may be configured to include a first fastening hole 212 , a second fastening hole 213 , a central hole 214 , a central line 215 and a side groove 216 .

[0053] A pair of the first fastening holes 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com