Middle stop guide rail system for rubber track vulcanization processing technology and vulcanization processing system

A technology of rubber track and guide rail system, applied in belts, applications, household appliances, etc., can solve the problems of high labor costs, safety accidents, easy to drop feet, etc., to save workshop space, good safety, and convenient loading and unloading operations Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention. In the following examples, those that are not described in detail are conventional technical means or common knowledge in the art.

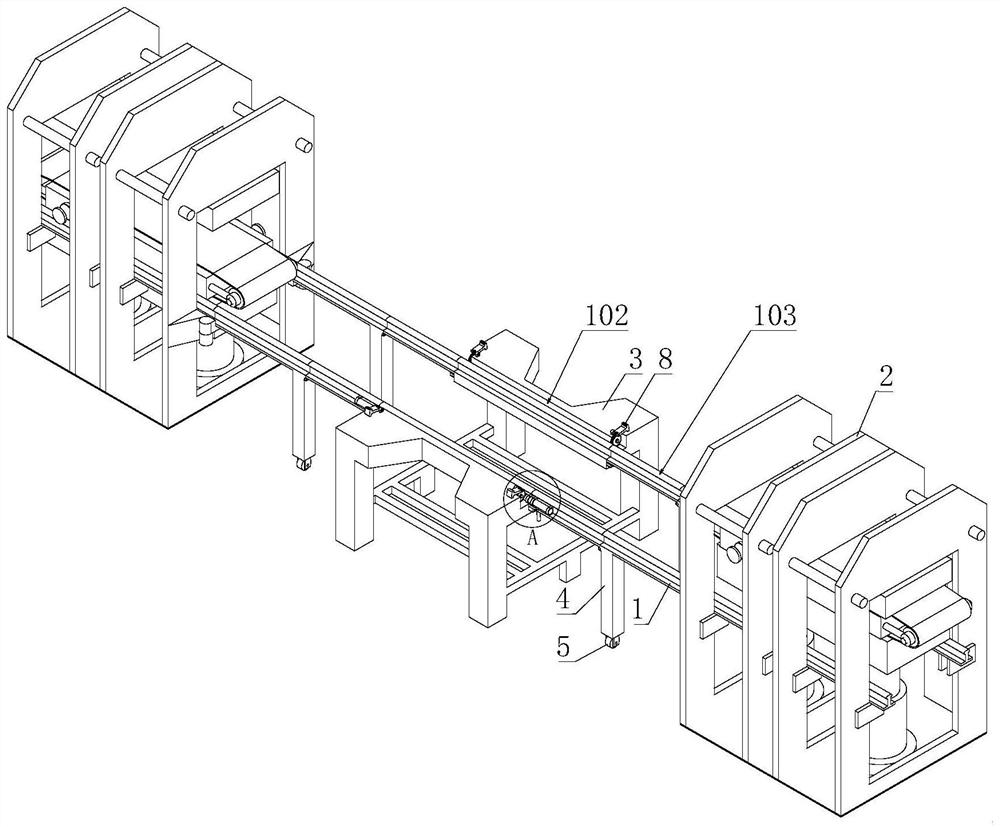

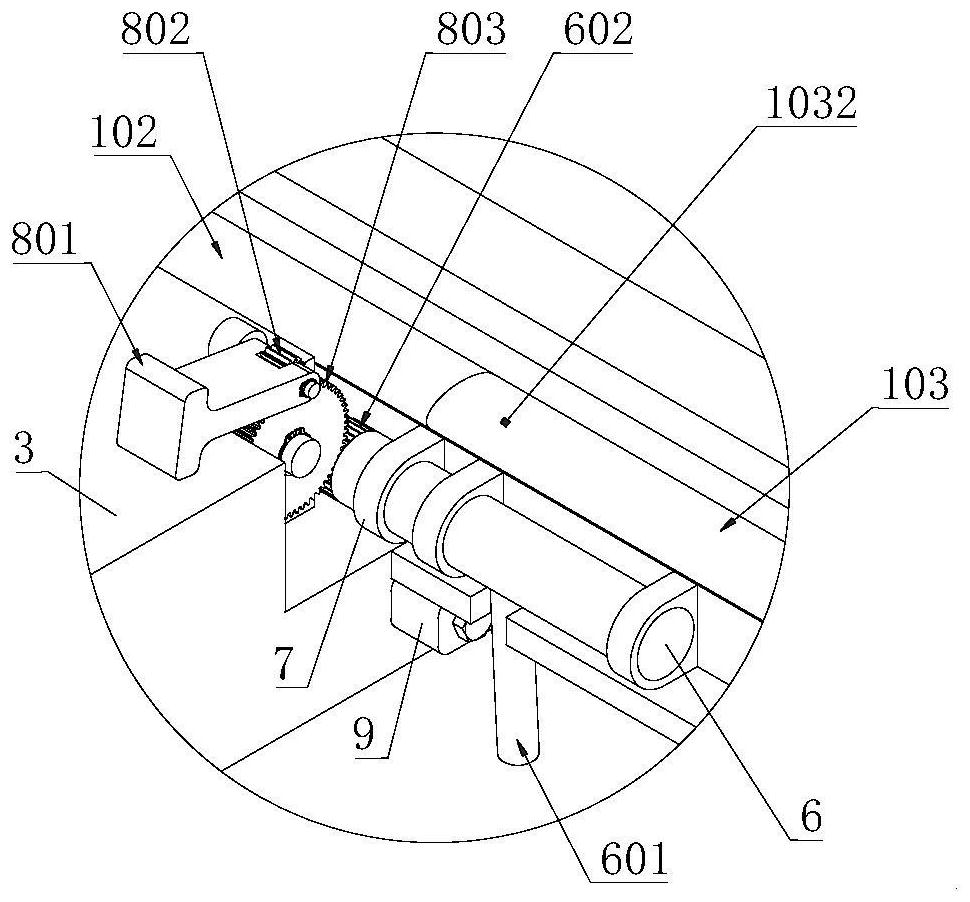

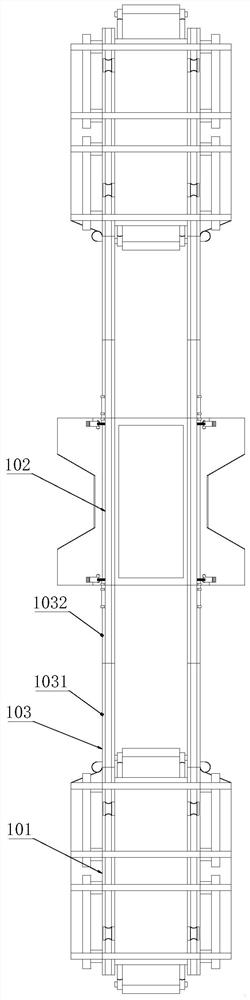

[0027] Examples (see Figure 1-6 ):

[0028] The intermediate guide rail system used in the rubber crawler vulcanization process of this embodiment includes a pair of parallel guide rails 1, and the guide rails 1 are fixedly arranged relative to the vulcanizer 2 and protrude from the inside of the vulcanizer 2. 101. The console rail section 102 fixed on 3, and the movable rail section 103 used to connect the inner rail section 101 and the console rail section 102; the movable rail section 103 includes A movable subsections 1031 and B Movable subsection 1032; the inner end of the A movable subsection 1031 is hinged with the guide rail section 101 in the machine, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com