Testing system and method for applying external magnetic field to liquid metal battery

A liquid metal battery and test system technology, applied in the field of electrochemical energy storage, can solve the problems of battery operating temperature exceeding, inability to select the time of applying a magnetic field, and poor stability of the magnetic field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

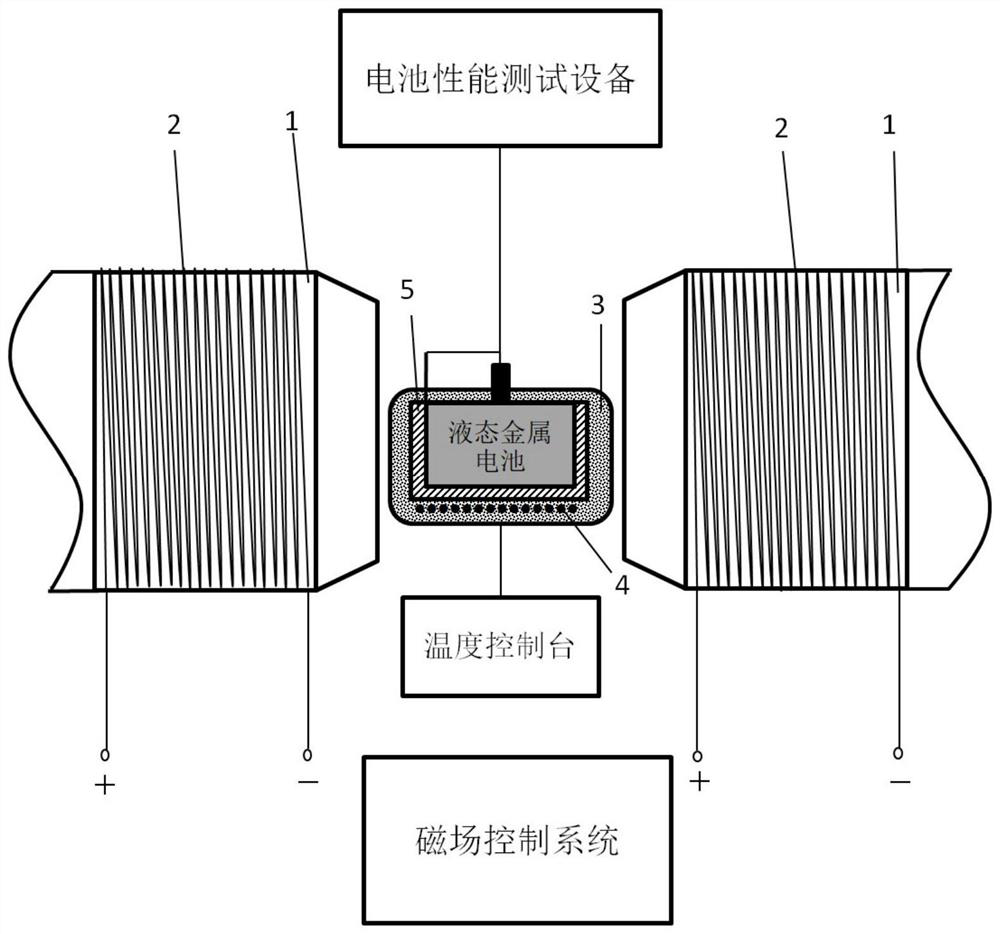

[0052] Such as figure 1 As shown, a horizontal magnetic field is applied to the liquid metal battery; two solenoids 2 are respectively arranged on the left and right sides of the liquid metal battery; the solenoid 2 selects a Cu wire with good conductivity. The number of turns of the solenoid 2 should be no less than 80 turns.

[0053] Number of turns vs. magnetic field is available In the formula, N is the number of turns, H is the applied magnetic field, and i is the maximum current of the solenoid 2; u r is the relative magnetic permeability of FeCo alloy, S 1 is the cross-sectional area of the solenoid 2, S 2 is the cross-sectional area of the central area of the sample test, l 1 is the magnetic path length of solenoid 2, l 2 Test the width of the central area for the sample. Select the relative permeability u of the FeCo alloy r is 8000, the diameter of solenoid 2 is 14cm, then S 1 0.0154m 2 , the diameter of the test center area is 8cm, then S 2 0.005m ...

Embodiment 2

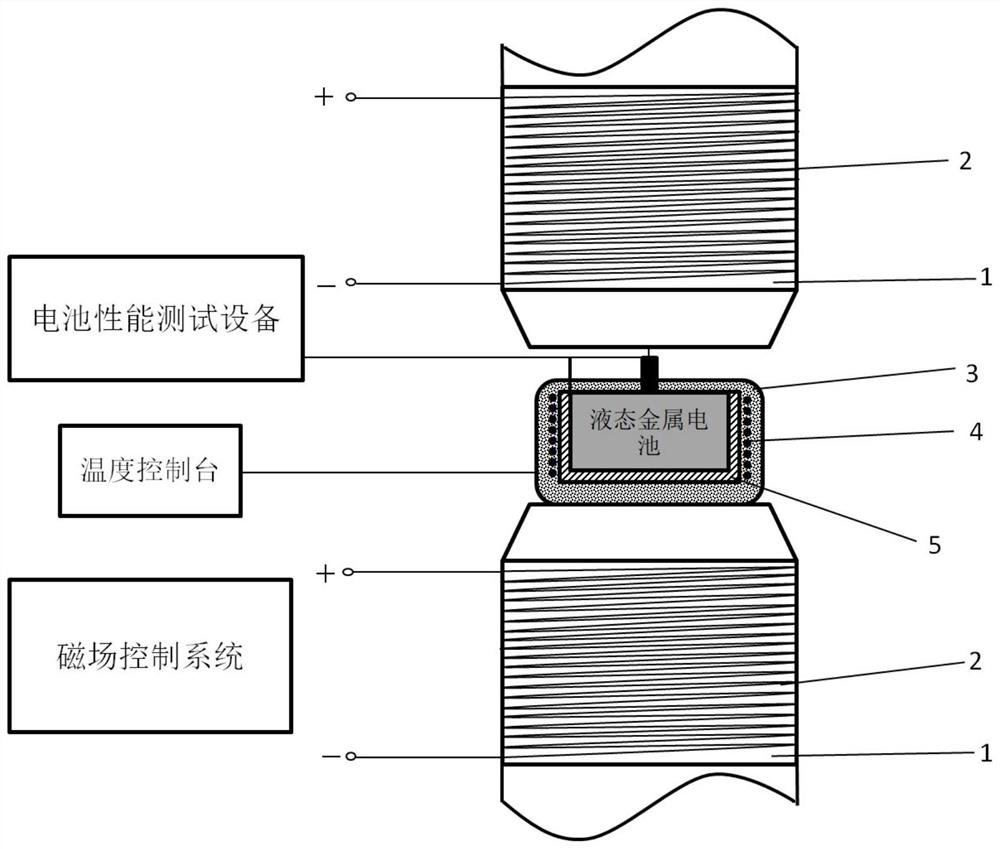

[0059] Such as figure 2 As shown, a vertical magnetic field is applied to the liquid metal battery; two solenoids 2 are arranged above and below the liquid metal battery; The number of turns, the calculation method is as shown in the embodiment;

[0060] Before the test, use a Gauss meter to measure the magnetic field strength at this place, give the relationship between the current and the magnetic field, and precisely control the strength of the applied magnetic field.

[0061] Heat conduction container 5 selects materials such as Cu alloy with excellent thermal conductivity;

[0062] The magnetic field control system converts the strength of the applied magnetic field by controlling the magnitude of the solenoid current. The current control accuracy is 1mA, and a periodically changing external magnetic field of 500A / m is applied;

[0063] The liquid metal battery test device is used to test the electrochemical parameters of the liquid metal battery, select the battery co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap