Single-stage suspension system and axle box built-in high-speed motor train unit non-power bogie

A suspension system and axle box technology, applied in the field of non-powered bogies of high-speed EMUs with built-in axle boxes, can solve the problems of not meeting the installation space requirements of the built-in axle box bogies, occupying the lateral space of the system, and not reducing space, etc. Achieve the effect of meeting the requirements of lightweight design, reducing the lateral space occupied, and reducing the wear of wheel and rail

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings.

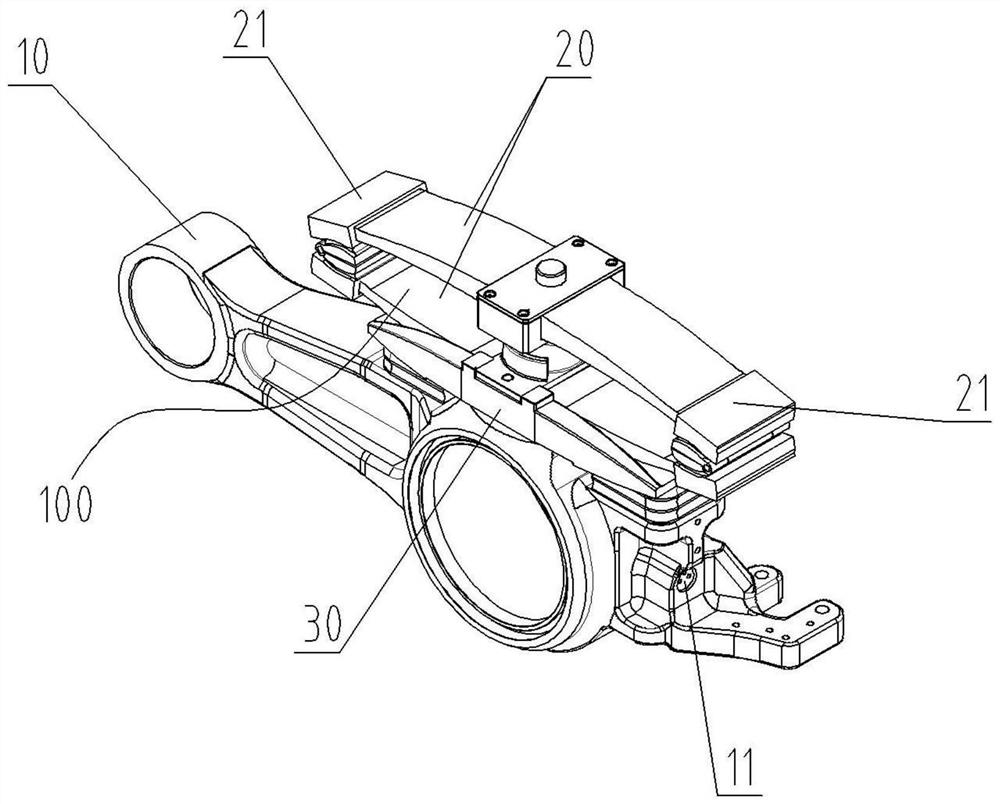

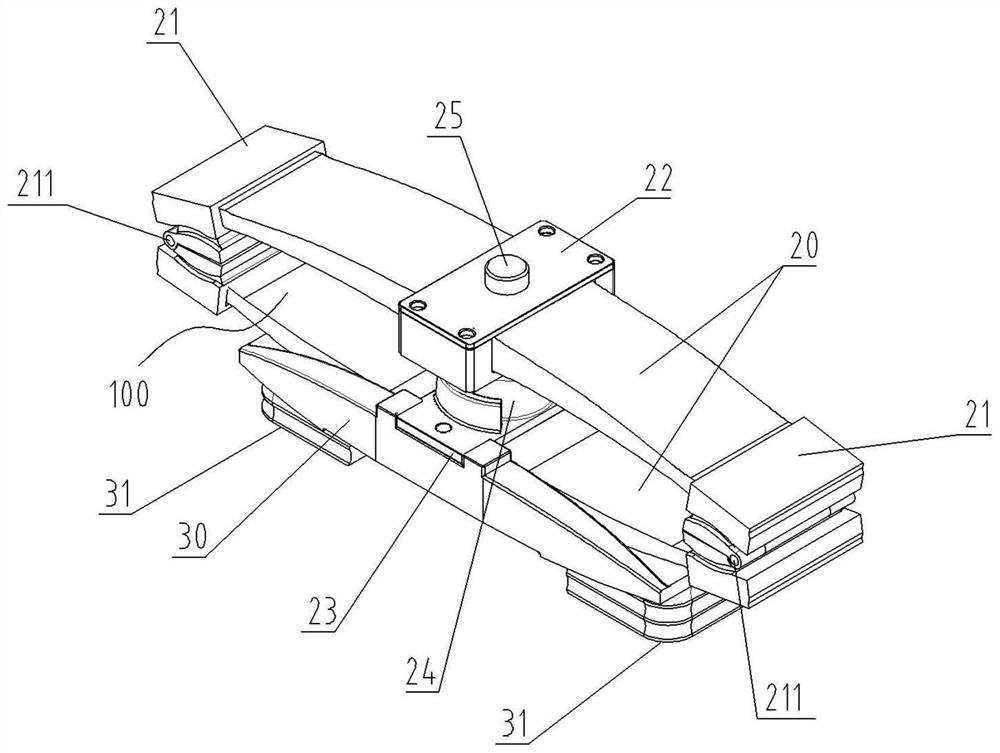

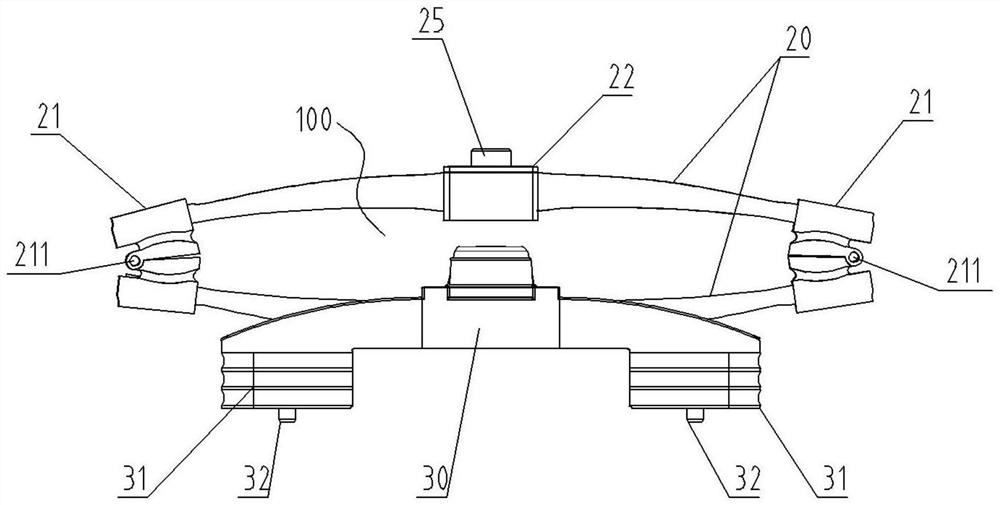

[0049] see figure 1 , 2 shown;

[0050] Invent a suspension system, which is placed inside the wheel set, and includes: axle box 10, a suspension spring;

[0051] The axle box body 10 is erected between the frame 40 and the hollow axle 50, and a series of suspension springs are installed between the axle box body 10 and the frame 40, and the axle box body 10 supports a series of suspension springs through the bearing area;

[0052] A series of suspension springs includes two fiberglass springs 20 and laminated springs 30,

[0053]The glass fiber spring 20 is formed by a molding mass production process, and the two glass fiber springs 20 are symmetrically arranged above the laminated spring 30, and the structure of the two glass fiber springs 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com