Hybrid module and drive device for motor vehicle

A driving device and motor vehicle technology, applied in the direction of motor vehicles, power devices, mechanical drive clutches, etc., to achieve the effect of small structural space requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

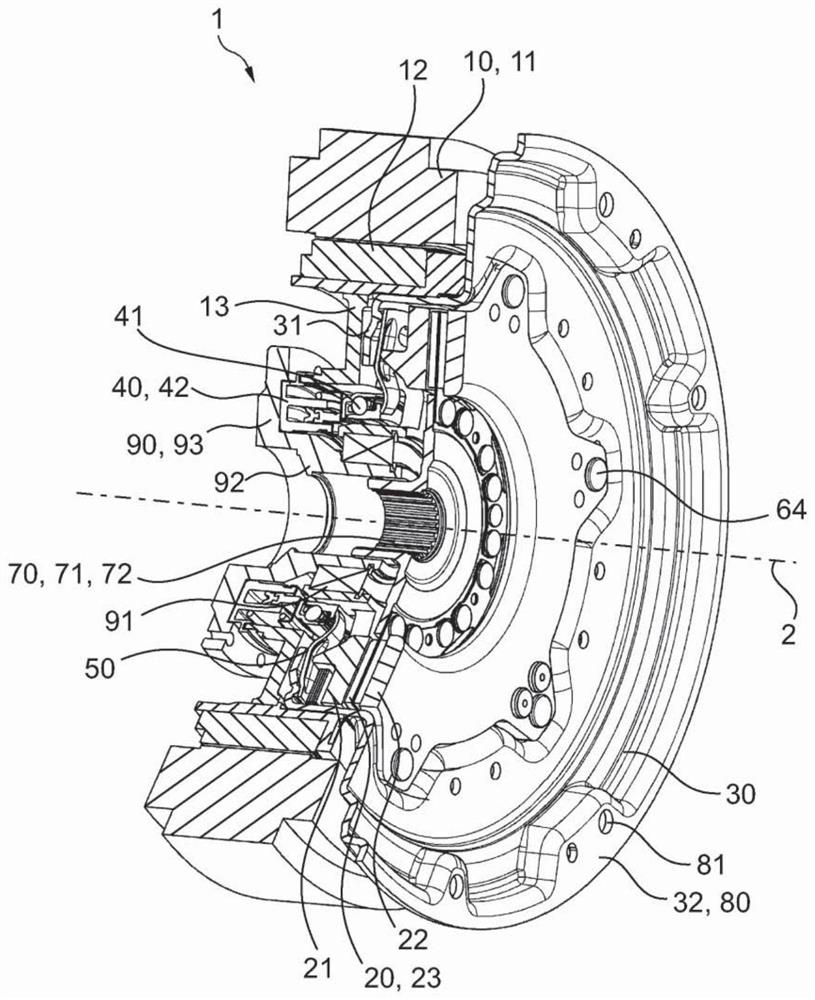

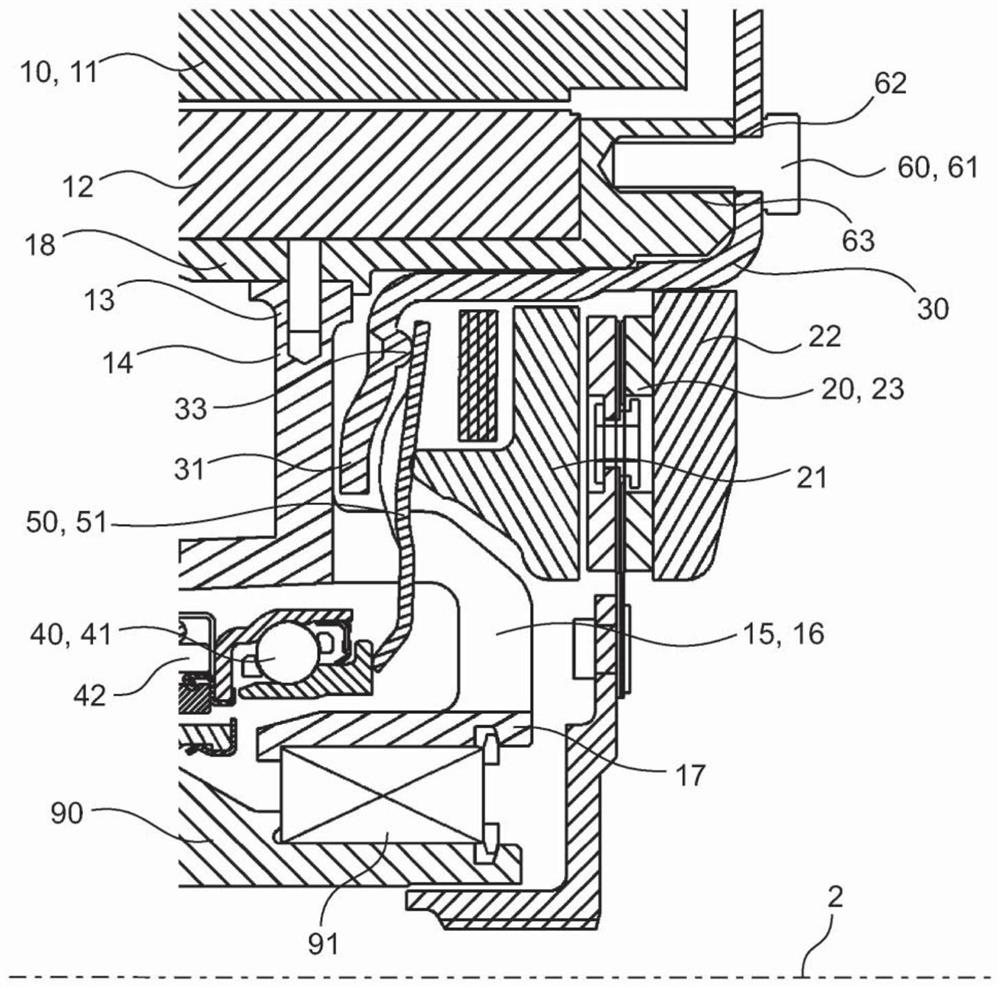

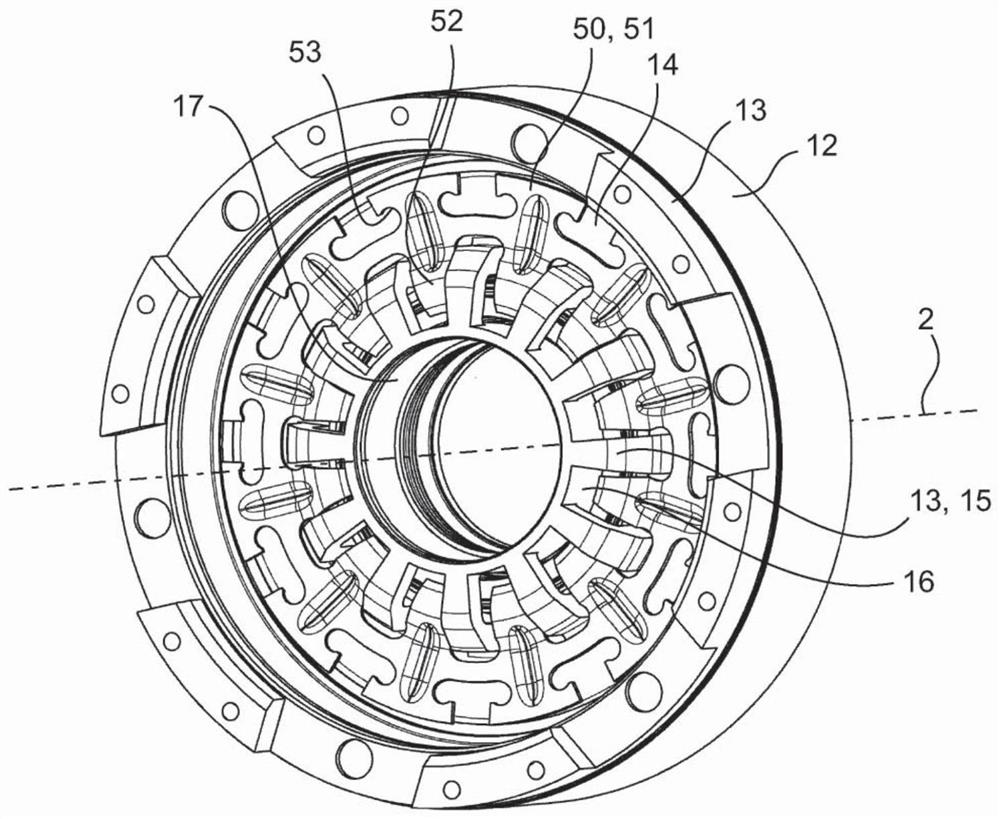

[0044] exist figure 1 A perspective sectional view of a hybrid module 1 according to the present invention is shown. The hybrid module 1 comprises an electric rotary machine 10 with a stator 11 and a rotor 12 , a disconnect clutch 20 , an actuation system 40 for actuating the disconnect clutch 20 and a force transmission element 50 .

[0045] The rotor 12 of the electric rotary machine 10 is arranged on a rotor carrier 13 which is supported via a support bearing 91 on a hollow cylindrical housing section 92 of a housing component 90 of the hybrid module 1 for The rotor 12 is mounted in rotation about the axis of rotation 2 of the hybrid module 1 . At the axial end region of the hollow-cylindrical housing section 92 , the housing component 90 also includes a radially extending housing section 93 by means of which the housing component 90 It can be connected to the remaining housing (not shown) of the hybrid module 1 or to the housing of an adjacent structural unit when the hy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com