Main bearing of heading machine and assembly method of main bearing

A technology for main bearings and roadheaders, applied in the direction of bearing components, roller bearings, shafts and bearings, etc., can solve problems affecting the running state and service life of main bearings of roadheaders, abnormal noise wear, collisions, etc., and achieve the goal of reducing skew Probability, avoidance of wear and collisions, effect of reducing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

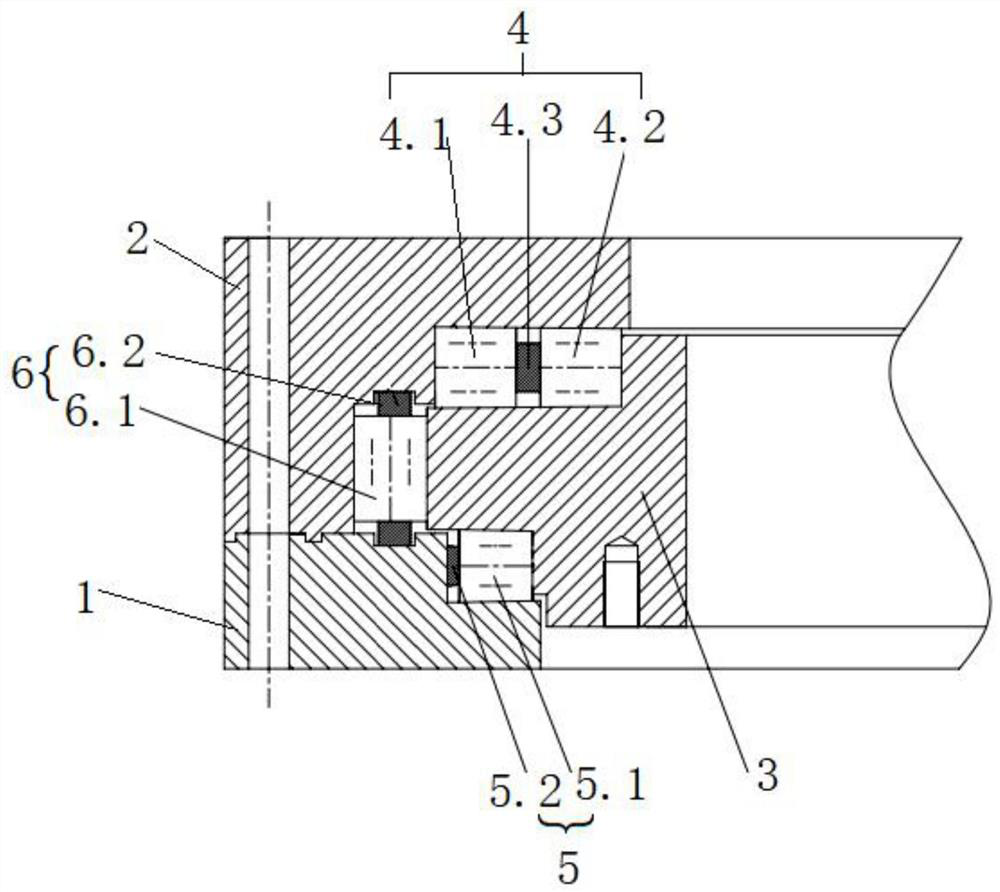

[0057] see Figure 1 to Figure 8 As shown, a roadheader main bearing provided by the present invention includes a first outer ring 1, a second outer ring 2, an inner ring 3, a main thrust roller assembly 4, an auxiliary thrust roller assembly 5 and a radial roller assembly 6 ; The first outer ring 1 is sleeved on the inner ring 3, and an auxiliary push raceway for installing the auxiliary push roller assembly is formed between the inner wall of the first outer ring 1 and the outer wall of the inner ring 3; 2 sets of second outer rings It is arranged on the inner ring 3, and the main thrust raceway for installing the main thrust roller assembly and the radial raceway for installing the radial roller assembly are formed between the inner wall of the second outer ring 2 and the outer wall of the inner ring 3 . Preferably here: the first outer ring 1 and the second outer ring 2 are connected to each other to form an outer ring assembly.

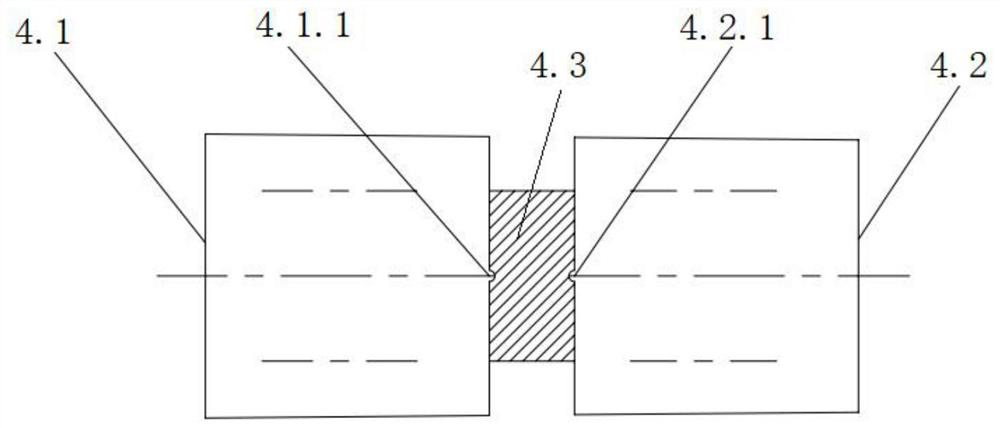

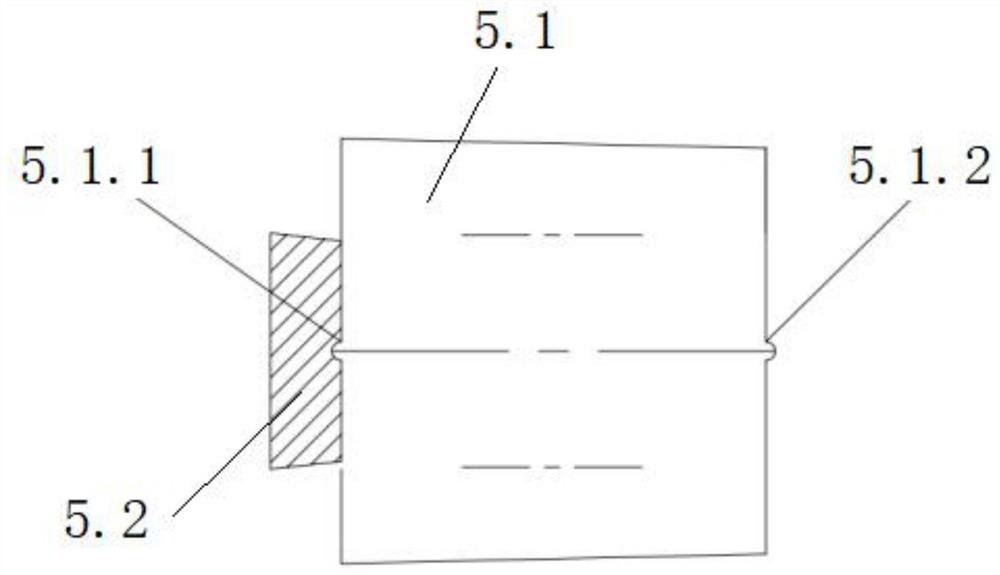

[0058] The main thrust roller assembly 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com