Movable scroll plate, scroll compressor and air conditioner

A scroll compressor and movable scroll technology, which is applied in the fields of scroll compressors, air conditioners and movable scrolls, can solve the problems of end face wear, oil shortage and wear on the end faces of the moving and static discs, and achieve the effect of reducing wear and tear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

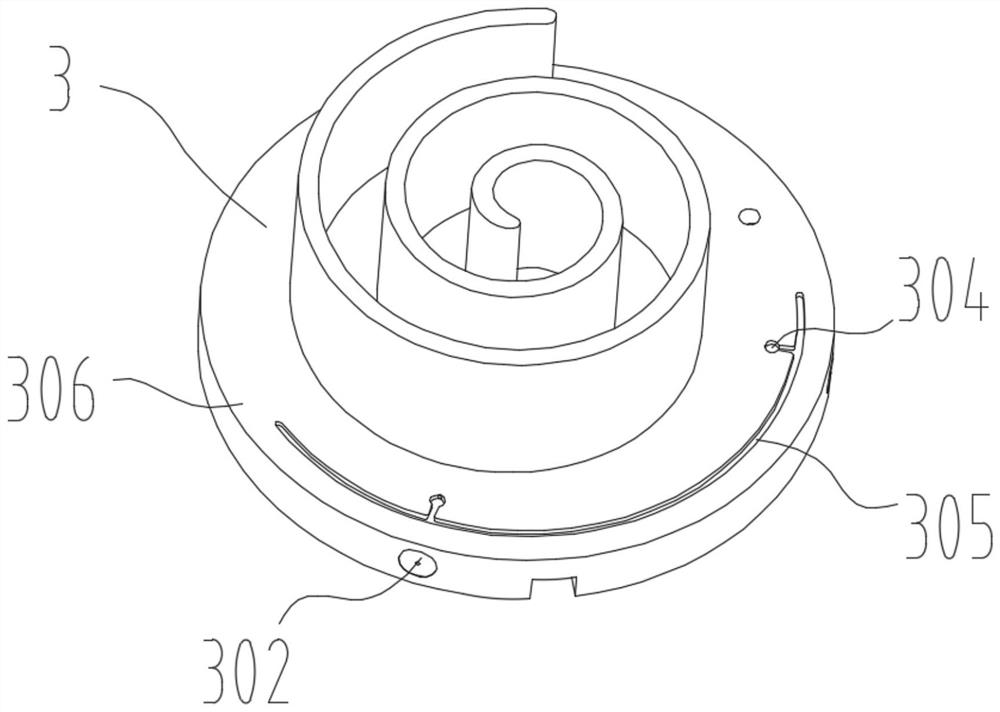

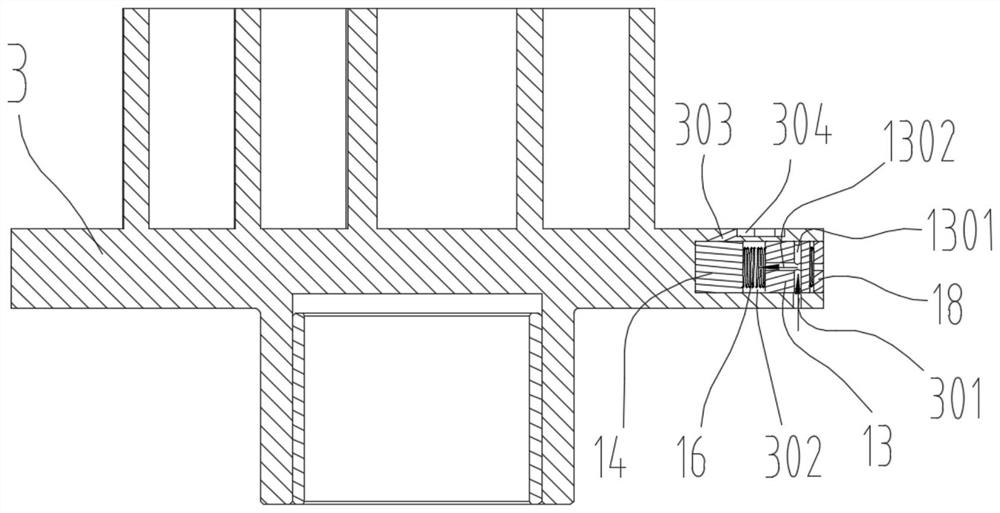

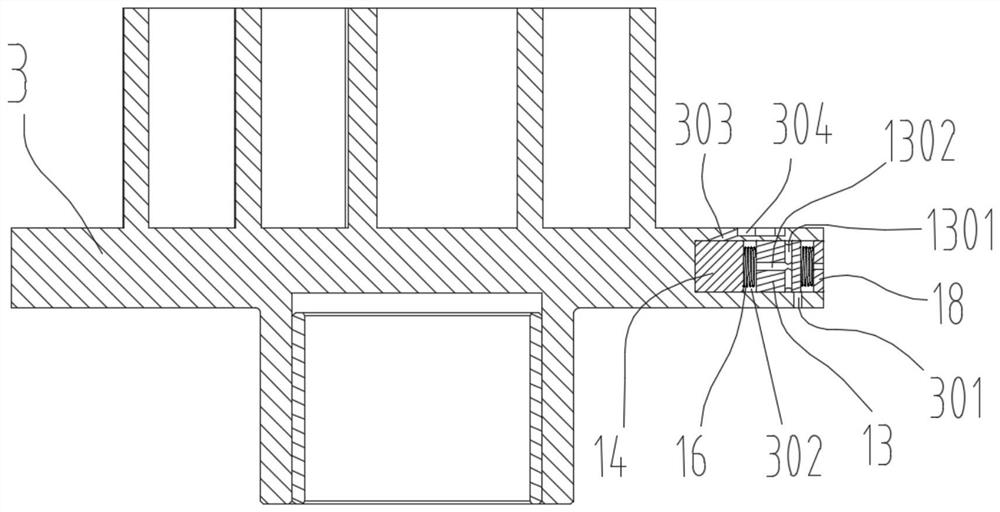

[0025] see in conjunction Figure 1 to Figure 7 As shown, according to an embodiment of the present invention, a movable scroll is provided, including a base plate 306, and a housing hole 302 is configured on the base plate 306, and an oil absorbing member 14 is arranged in the housing hole 302, and the base plate 306 has a first oil groove 304 communicating with the accommodating hole 302 on the first side, and when the oil absorbing member 14 is squeezed, the lubricating oil absorbed in it can enter the base plate 306 through the first oil groove 304 The first side of the substrate 306 is the side with the spiral teeth. In this technical solution, lubricating oil can be stored in the oil absorbing member 14, and can be squeezed into the first oil groove 304, so as to solve the problem between the movable scroll 3 and the fixed scroll when the compressor is just started. The lack of oil on the mating surface 201 between the two reduces the wear of the friction pair formed by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com