Method and machine for cutting a covering element

A technology covering components and machines, which is applied in metal processing and other directions, can solve the problems of foreign matter in stacked layers, and achieve the effect of saving time and reducing risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

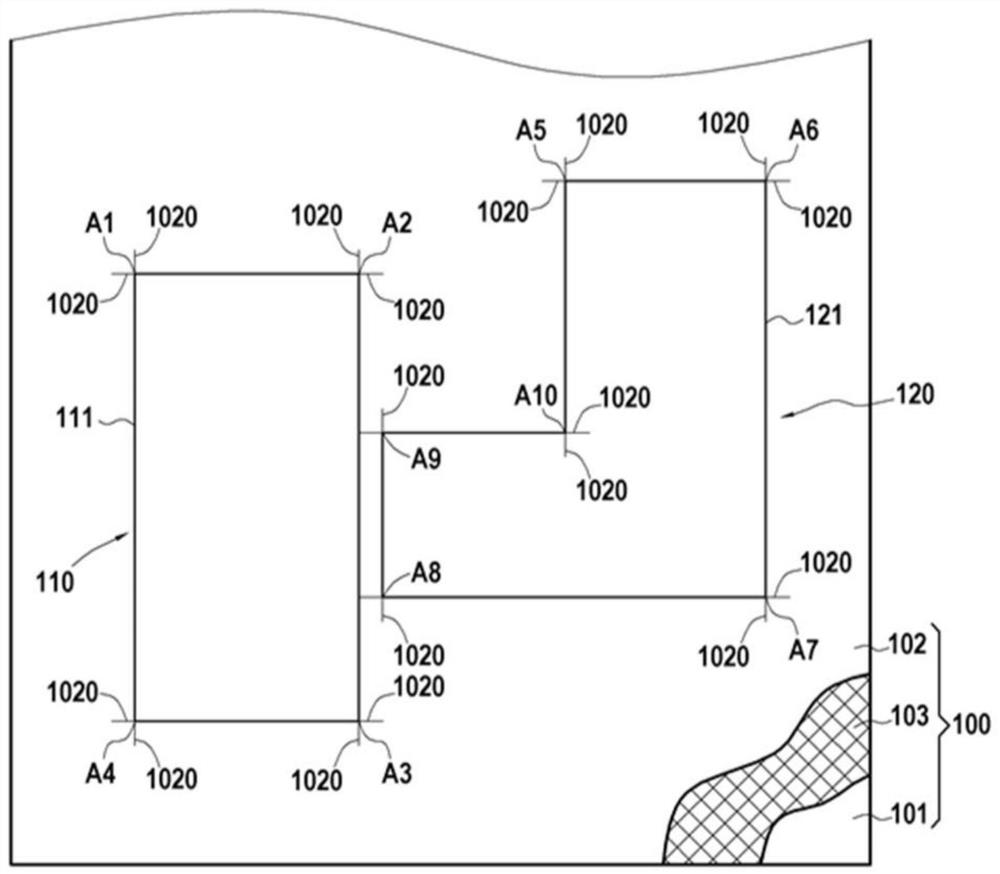

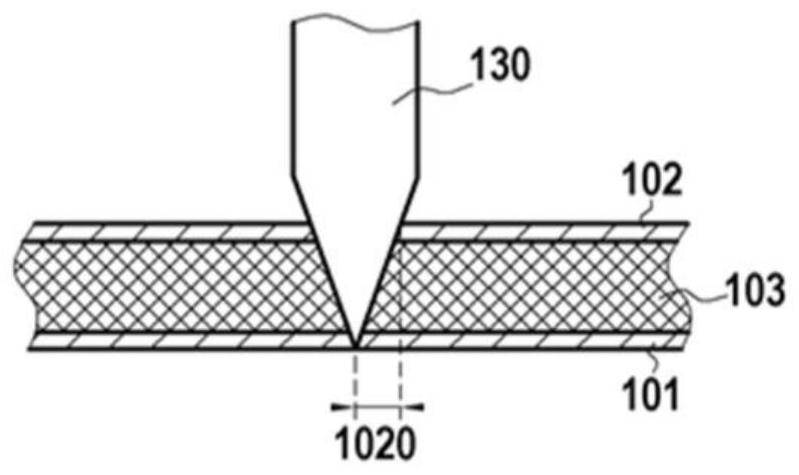

[0022] Generally, the invention applies to the cutting of plies or layers in a strip of material comprising a dry or pre-impregnated fabric layer and having a film on at least one face thereof which is cut simultaneously with the fabric layer. The invention has particular application in the manufacture of composite parts by covering fibrous layers pre-impregnated with matrix precursor resin.

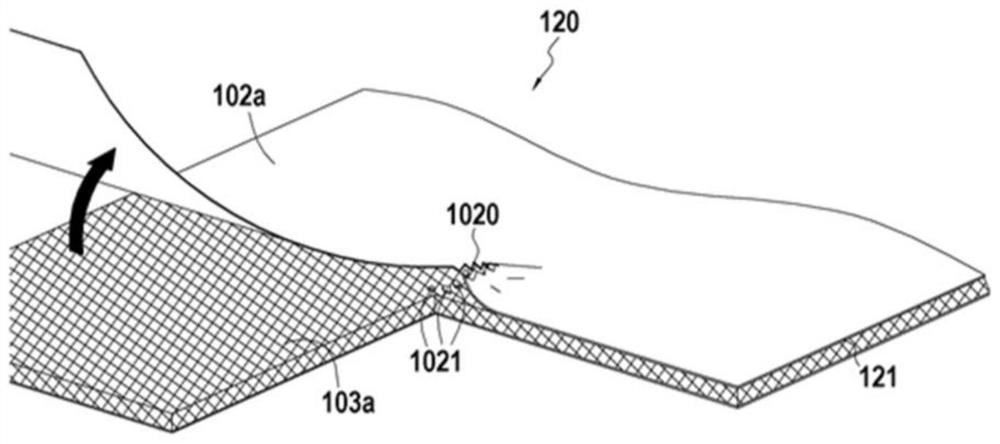

[0023] The layers used in the production of composite parts by covering are previously cut out from usually pre-impregnated fabric layers, and this fabric layer is in the form of a strip covered with a release film on one or both sides, to avoid impregnation due to There is resin in direct contact with the bonding or adhesive layer. When the layer is covered on the covering mould, the operator peels off one or more film portions present on one or more faces of the covering element.

[0024] The inventors have found that the material of the release film present on the face or faces of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com