LED driving system for plant illumination and plant illumination system

A technology for LED driving and plant lighting, which is applied in the direction of electrical components, etc., and can solve problems such as high heat dissipation and high power loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

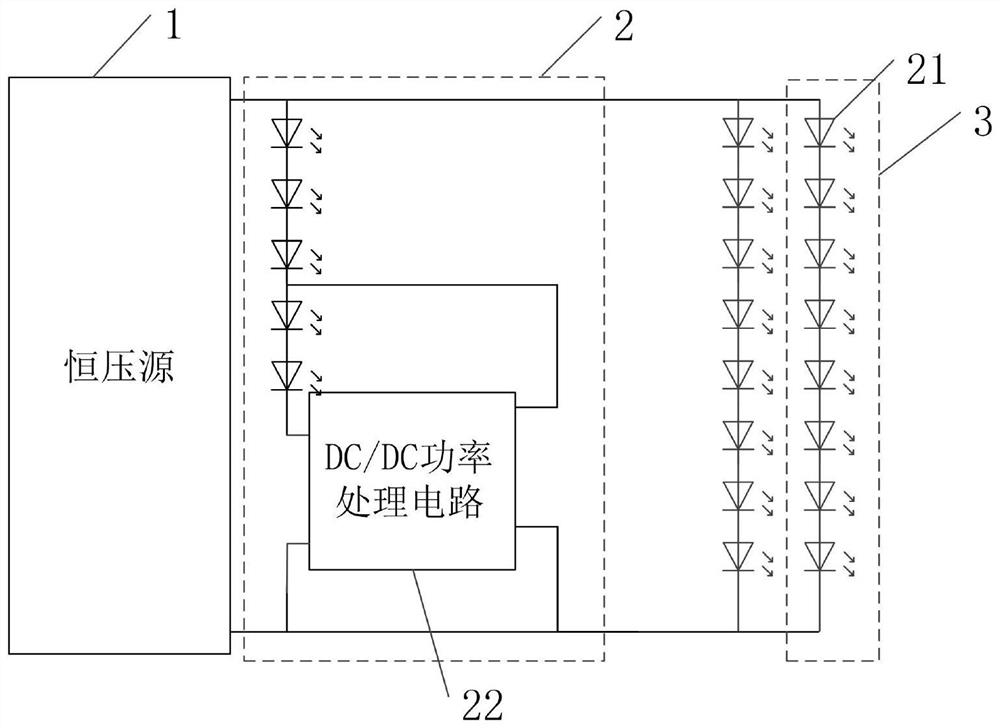

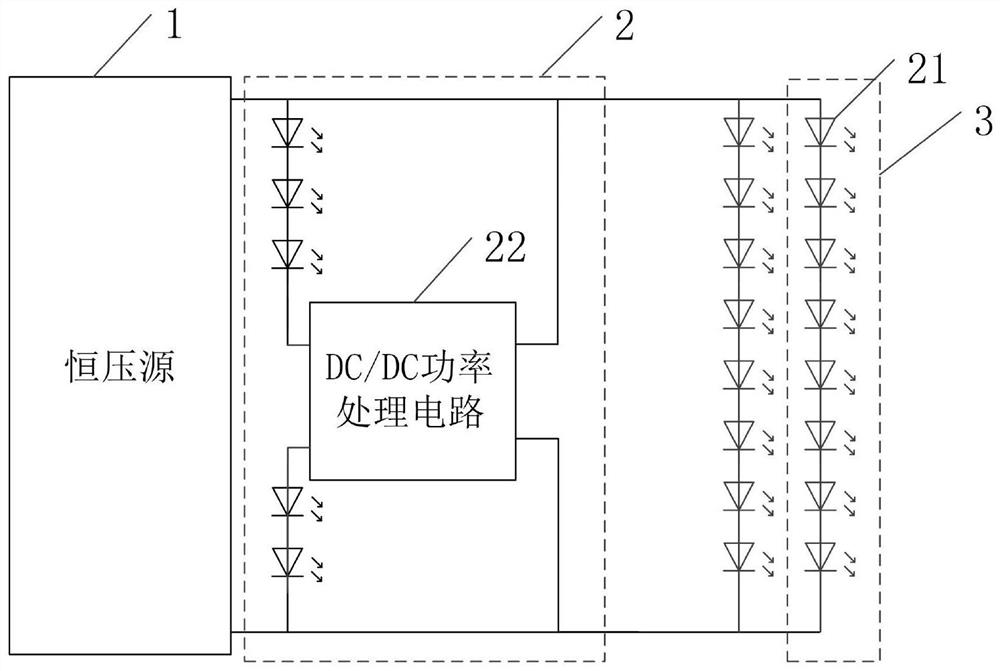

[0038] Such as Figure 1-8 As shown, the embodiment of this specification provides an LED drive system for plant lighting, including:

[0039] constant voltage source 1,

[0040] At least one first LED circuit 2, the first LED circuit 2 is electrically connected to both ends of the constant voltage source 1, the first LED circuit 2 includes a plurality of lamp bead units and a DC / DC power processing circuit 22, the DC / DC power processing circuit 22 through its positive input terminal, negative input terminal and multiple lamp bead units in series in sequence, the positive output terminal of the DC / DC power processing circuit 22 is electrically connected to the positive pole of one of the lamp bead units in the first LED circuit 2, and the DC / DC The negative output terminal of the power processing circuit 22 is electrically connected to the negative terminal of the constant voltage source 1, the lamp bead unit is composed of at least one LED lamp bead 21, and the DC / DC power p...

Embodiment approach

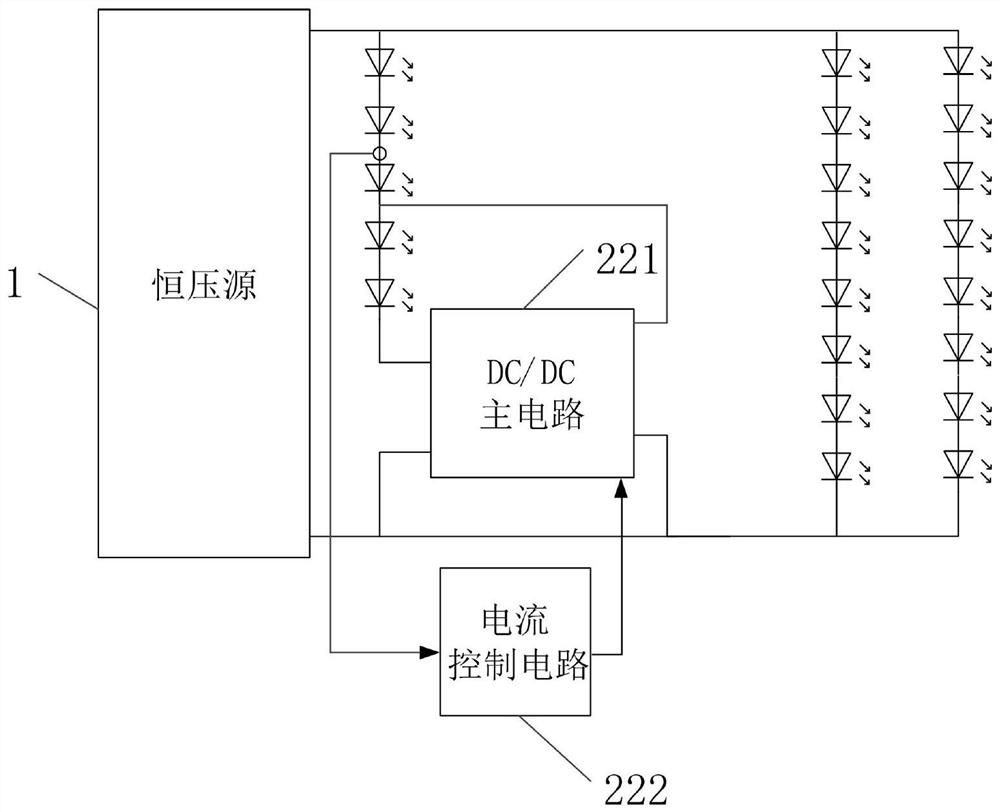

[0051] In one embodiment, as image 3 As shown, the DC / DC power processing circuit 22 includes a DC / DC main circuit 221 and a current control circuit 222, the current control circuit 222 includes a proportional integral circuit, and the current control circuit 222 is set to pass the detected current of the first LED circuit 2 The value is input into the proportional integral circuit so that the output voltage amplitude of the proportional integral circuit adjusts the input power of the DC / DC main circuit 221 to control the current value of the first LED circuit 2 to be equal to the current preset value, and the output voltage amplitude of the proportional integral circuit The value and the difference between the detected current value of the first LED circuit 2 and the current preset value are in a proportional-integral relationship.

[0052] Wherein, the current control circuit 222 is used to detect the current of the first LED circuit 2 connected to the input end of the DC / D...

Embodiment 2

[0070] The embodiment of this specification provides a plant lighting system, including multiple LED drive systems for plant lighting in Embodiment 1. A plant lighting system includes a plurality of LED driving systems in Embodiment 1, that is, includes a plurality of constant voltage sources 1, and each constant voltage source 1 is electrically connected to a plurality of first LED circuits equipped with a DC / DC power processing circuit 22 2. It is convenient to realize accurate control of LED driving systems corresponding to different plant lighting areas.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com