Artificial texture stone surface layer sanding equipment

A technology of sand laying and texture, applied in the field of sand laying equipment on the surface of artificial textured stone, can solve the problems of inability to realize control-type negative pressure extraction, inability to realize coordinated sand laying, inconvenient control and output, etc., to achieve convenient symmetrical drainage, Convenient and smooth connection, improve the effect of running efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

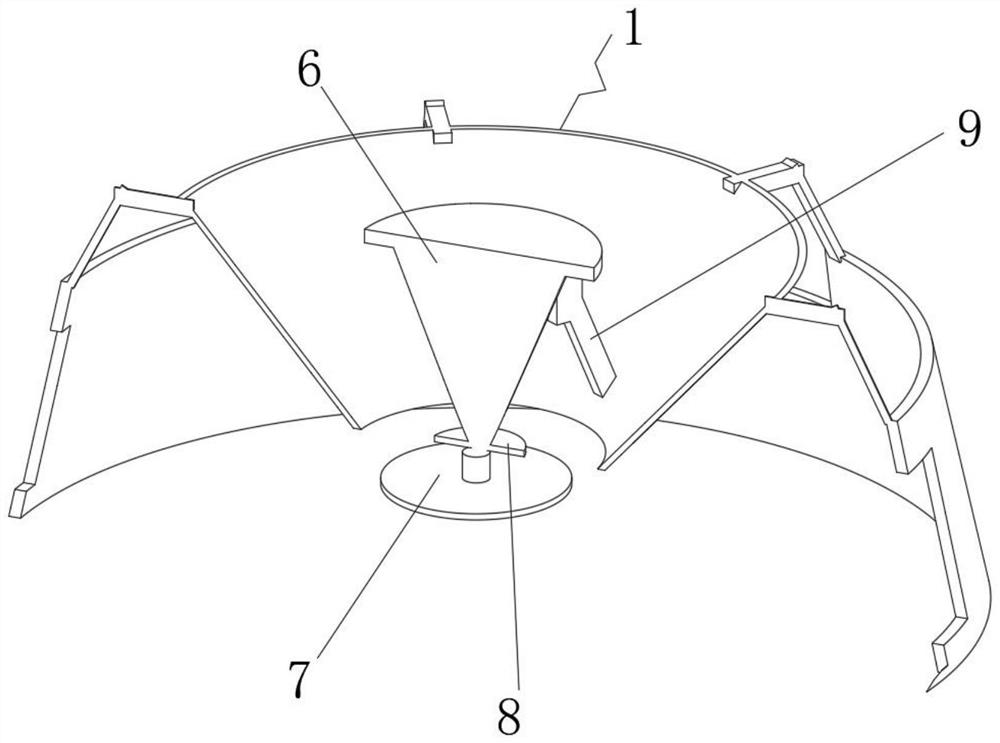

[0030] see Figure 1-8 , the present invention provides a technical solution: a sanding device for the surface of artificial textured stone, including a feeding blocking device 1, the lower end of the feeding blocking device 1 is fixedly connected with a sanding conducting device 2, and by installing the sanding conducting device 2 , the inner end of the sand-laying conduction device 2 is composed of a supporting connecting part 10 and an adjusting contact part 11. The structural setting of the supporting connecting part 10 is convenient for moving the platform, and at the same time, it can provide the driving function of the inner end and provide the basis for internal movement. By adjusting the setting of the contact part 11, adjusting the inner end of the contact part 11 can realize the control-type negative pressure extraction, which is convenient for the regulation and output of the inner end, and is driven by the movement of the inner end to better transmit the sand parti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com