Vehicle center line calibration method and system

A calibration system and centerline technology, applied in the vehicle centerline calibration method and system field, can solve problems such as large measurement errors, errors caused by elastic deformation of tape measures, and observation angle errors, so as to reduce labor costs, avoid large errors, and ensure The effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

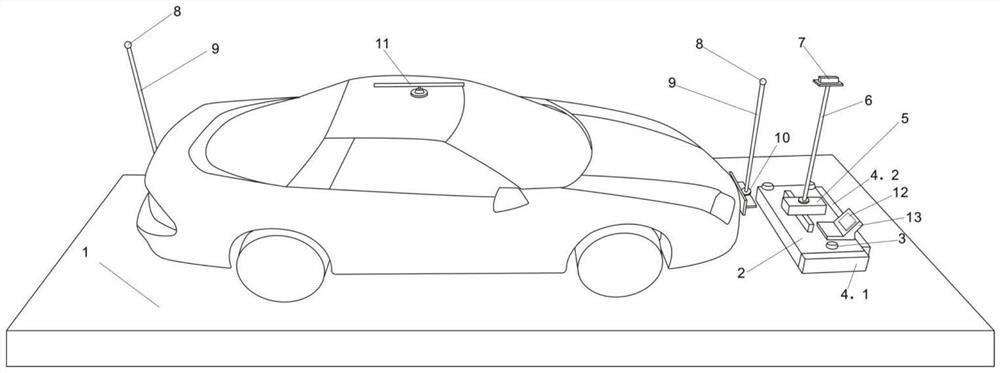

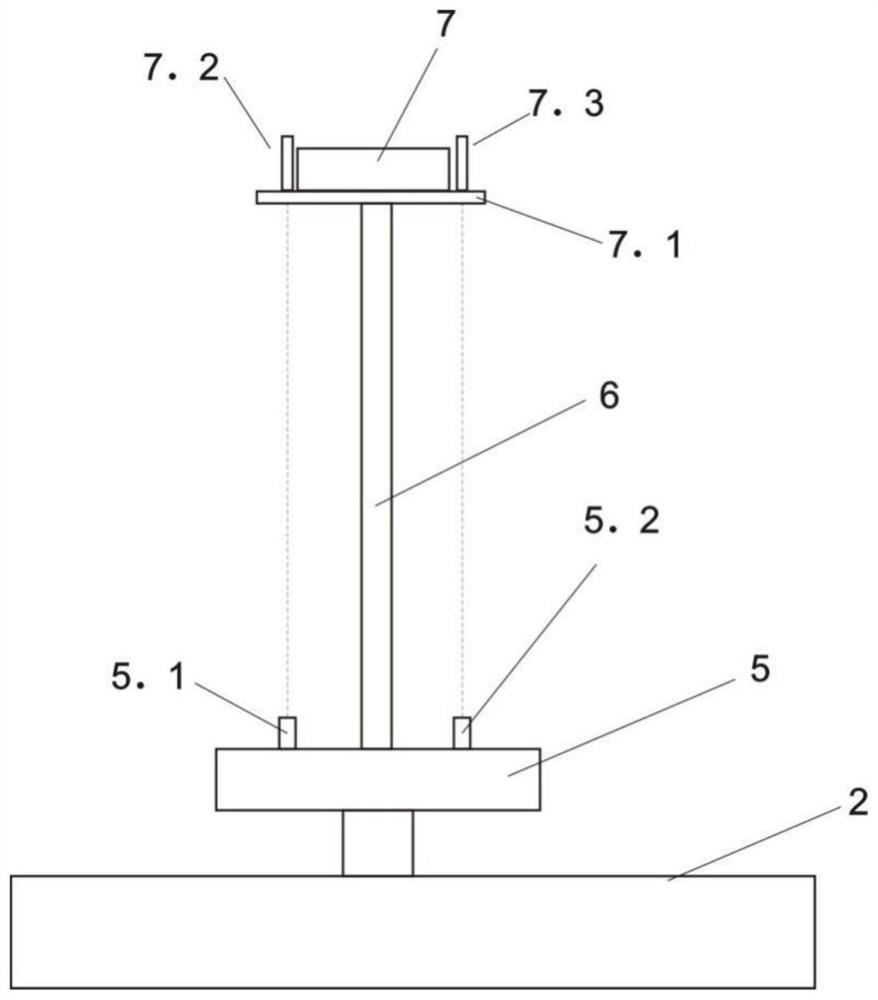

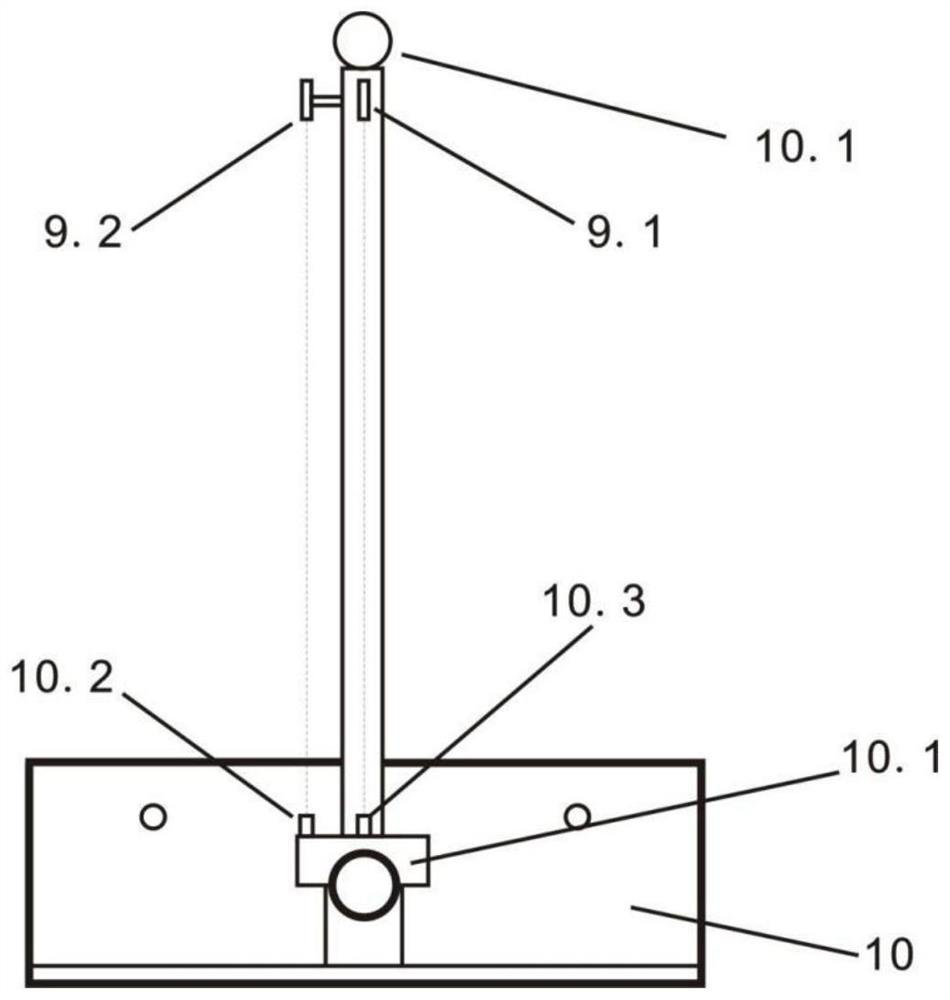

[0060] figure 1 Among them, the system for demarcating the center line of the vehicle of the present invention includes a vehicle reference device, a vehicle attitude detection device, a calibration device, and a controller 12; the vehicle reference device includes a front reference device and a rear reference device with the same structure, and The reference device is installed in the front and rear license plate frames of the vehicle to be calibrated, and is used to obtain the reference center line Y0 of the vehicle through two points; the vehicle to be calibrated is located on the preset metal platform 1, and the function of the vehicle attitude detection device is to automatically move and lift Look for the hard points protruding vertically from the front reference device and the rear reference device on the license plate frame of the vehicle body. The vehicle posture detection device includes the body support 2, and the body support 2 is provided with one end of the metal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com